Preparation technology for graphene conductive printing ink

A technology of conductive ink and preparation process, which is applied in ink, household utensils, applications, etc. It can solve the problems that the conductive properties of carbon black, graphite and carbon fiber cannot meet the development needs, and achieve a large market application prospect, low curing temperature, and volume resistance. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

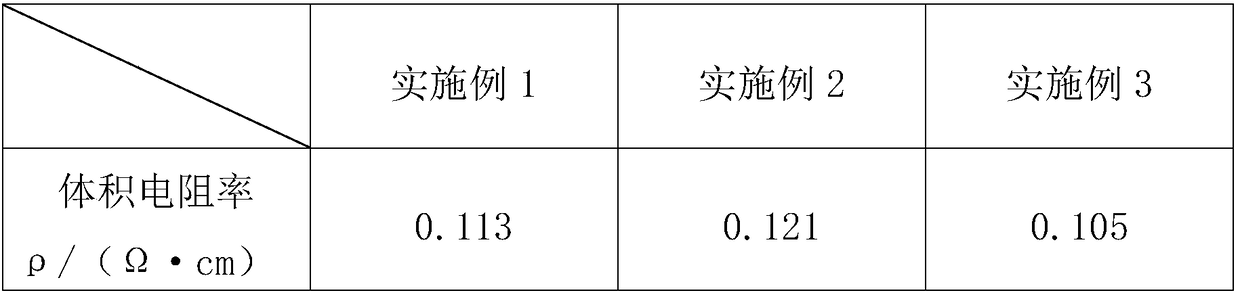

Embodiment 1

[0025] A kind of preparation technology of graphene conductive ink, comprises the following steps:

[0026] (1) Use the mixed acid solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 to pretreat flake graphite. The pretreatment time is 35 minutes, and the pretreatment temperature is 60°C. Then add potassium perchlorate powder, flake graphite and high The mass ratio of potassium chlorate powder is 120:1. After being sealed and oxidized for 7 hours, add hydrogen peroxide solution dropwise at room temperature, stir for 1-3 hours, then filter with suction, rinse with dilute hydrochloric acid with a mass concentration of 10%, and then use deionized After washing with water until neutral, put it in an oven and dry it at 75°C, add the obtained graphene oxide into deionized water, ultrasonically vibrate and peel off, after peeling, evaporate at low temperature, and evenly disperse the brown graphene oxide solution;

[0027] (2) Configure a ce...

Embodiment 2

[0032] A kind of preparation technology of graphene conductive ink, comprises the following steps:

[0033](1) Use a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid at a volume ratio of 5:1 to pretreat the flake graphite. The pretreatment time is 45 minutes, and the pretreatment temperature is 55°C. Then add potassium perchlorate powder, flake graphite and high The mass ratio of potassium chlorate powder is 130:1. After being sealed and oxidized for 5 hours, add hydrogen peroxide solution dropwise at room temperature, stir for 1-3 hours, then filter with suction, rinse with dilute hydrochloric acid with a mass concentration of 11%, and then use deionized After washing with water to neutrality, put it in an oven and dry it at 78°C, add the obtained graphene oxide into deionized water, ultrasonically vibrate and peel off, after peeling, evaporate at low temperature, and evenly disperse the brown graphene oxide solution;

[0034] (2) Config...

Embodiment 3

[0039] A kind of preparation technology of graphene conductive ink, comprises the following steps:

[0040] (1) Use a mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 1:1 to pretreat flake graphite. The pretreatment time is 30 minutes, and the pretreatment temperature is 50 ° C. Then add potassium perchlorate powder, flake graphite and high The mass ratio of potassium chlorate powder is 100:1. After being sealed and oxidized for 5 hours, add hydrogen peroxide solution dropwise at room temperature, stir for 1-3 hours, then filter with suction, rinse with dilute hydrochloric acid with a mass concentration of 8%, and then use deionized After washing with water to neutrality, put it in an oven and dry it at 70°C, add the obtained graphene oxide into deionized water, ultrasonically vibrate and peel it off, after peeling off, evaporate at low temperature, and evenly disperse the brown graphene oxide solution;

[0041] (2) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com