A kind of preparation method of positive electrode slurry

A positive electrode slurry and specific surface technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve problems such as negative impact on battery performance, difficulty in dispersion, and graphene barriers, and achieve the effects of reducing difficulties, reducing impact, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

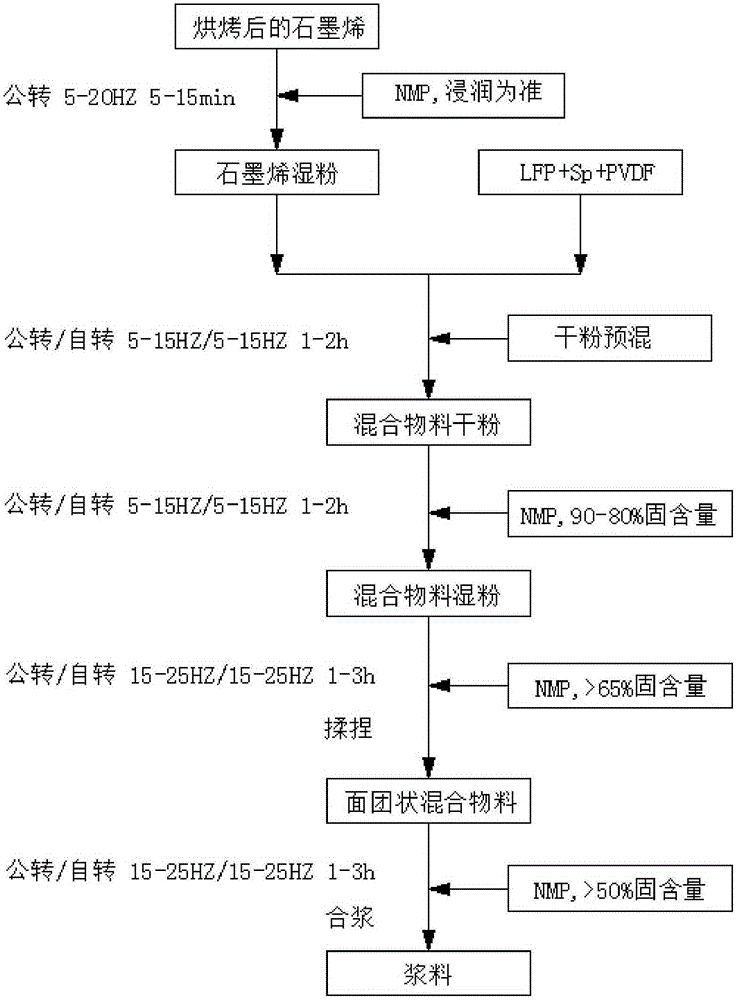

[0019] figure 1 It is a preparation process of positive electrode slurry, including the following 6 steps:

[0020] (1) Seal the graphene powder and place it in a 150°C oven for 24-48 hours in a vacuum oven, and the moisture content of the tested powder is <500ppm;

[0021] (2) Put the baked graphene into a mixer, infiltrate it with NMP, stir at a low speed for 5-15min to make a graphene wet powder, and the equipment parameters revolve at 10Hz;

[0022] (3) Add the baked positive electrode active materials (LFP, SP, PVDF) into the mixer in turn and pre-mix with the graphene wet powder for 1-2 hours. The parameters of the mixer are: revolution / rotation 10 / 6.6Hz;

[0023] (4) Add NMP, and now the solid content is controlled at about 80-90%, so that the mixed material is in a wet powder state and continues to premix;

[0024] (5) Add NMP to make the premixed material into a dough state, turn on the mixer to knead the mixed material, control the solid content at this time above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com