Planar coil diaphragm loudspeaker and application thereof

A planar coil and speaker technology, applied in the field of electro-acoustics, can solve the problems of inability to transfer coils, increase in product cost, and insufficient low-frequency sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

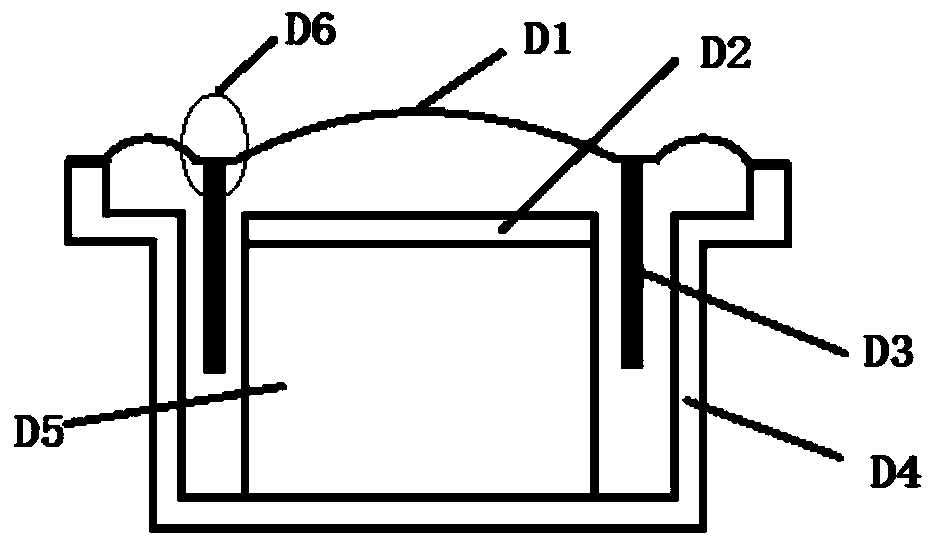

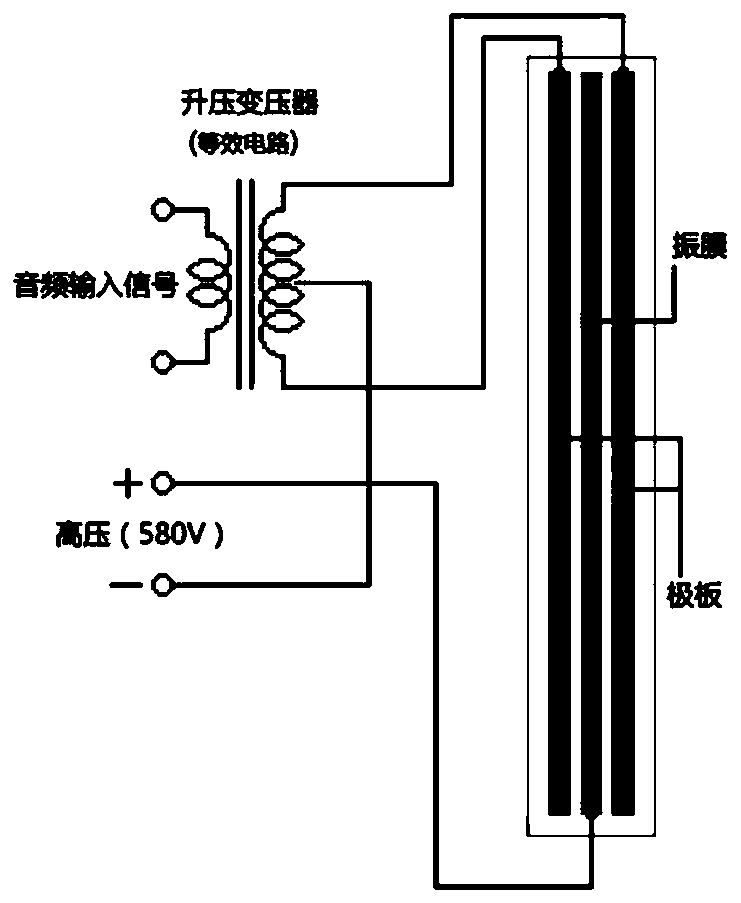

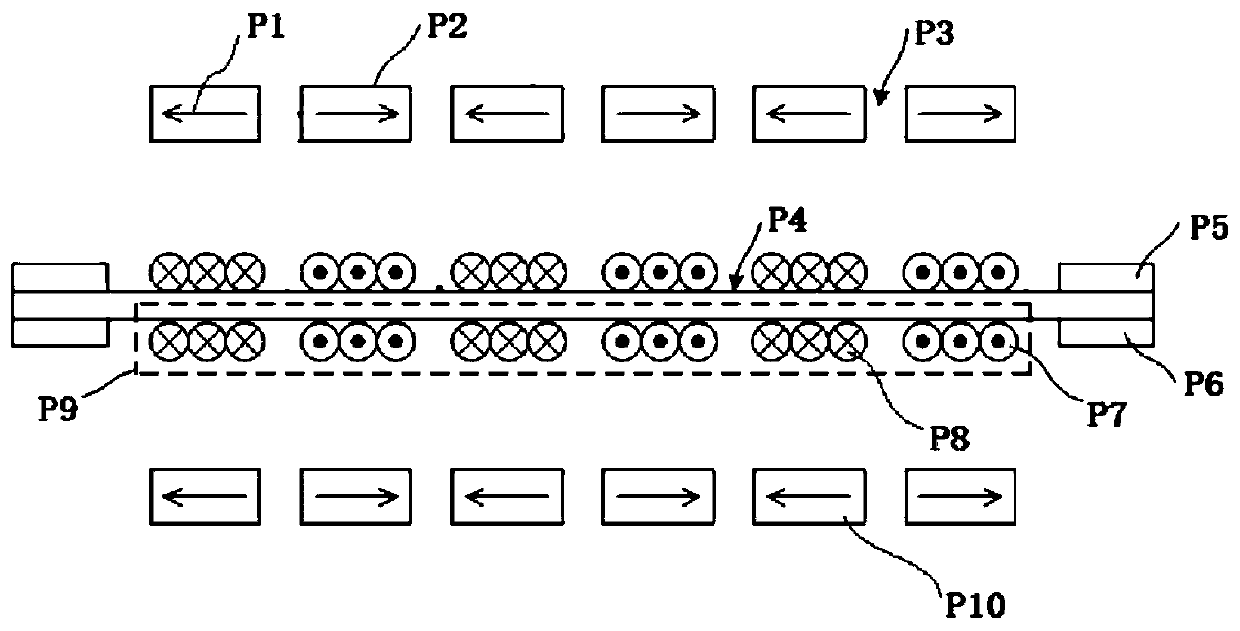

[0091] Such as Figure 7 , Figure 9 , Figure 10 and Figure 11 As shown, a planar coil diaphragm speaker includes a diaphragm assembly 5, the diaphragm assembly 5 includes a diaphragm 5a, the upper surface and the lower surface of the diaphragm 5a are respectively attached with a front coil 5d and a reverse coil 5g, and the front coil 5d and the reverse coil 5g is arranged mirror-symmetrically with the central plane of the vibrating membrane 5a as the plane of symmetry.

[0092] The routing mode of the front coil 5d and the rear coil 5g is spiral routing.

[0093] The two ends of the front coil 5d are respectively provided with a first end point 5e and a second end point 5f, the second end point 5f is located outside the front coil 5d, and the first end point 5e is located inside the front coil 5d; the two ends of the back coil 5g The ends are respectively provided with a third end point 5h and a fourth end point 5j, the fourth end point 5j is located outside the reverse...

Embodiment 2

[0120] The same part as that of Embodiment 1 has been discussed in detail in Embodiment 1, and will not be repeated here. Compared with Embodiment 1, this embodiment is modified as follows:

[0121] Such as Figure 17-Figure 19 As shown, the membrane assembly 5 includes a ring diaphragm 15, the diaphragm 15 replaces the diaphragm 5a, the center of the diaphragm 15 is provided with an inner ring 5m, and the outer edge is provided with an outer ring 5k, compared with the completely flat diaphragm 5a, adding two rings can increase the compliance of the diaphragm to vibrate up and down, that is, the diaphragm is easier to vibrate up and down.

[0122] In order to increase the rigidity of the membrane inner ring 5m and the membrane outer ring 5k, patterns can also be provided on the two rings, and the two rings and the patterns on the rings can be formed by hot pressing.

[0123] A front coil 5d and a back coil 5g are respectively attached to the upper surface and the lower surfac...

Embodiment 3

[0132] The same part as that of Embodiment 1 has been discussed in detail in Embodiment 1, and will not be repeated here. Compared with Embodiment 1, this embodiment is modified as follows:

[0133] Such as Figure 20 and 21As shown, the magnet assembly includes an upper vertically magnetized outer magnetic ring 13b, an upper vertically magnetized inner magnetic ring 14b, a lower vertically magnetized outer magnetic ring 13 and a lower vertically magnetized inner magnetic ring 14. The outer magnetic ring 13b for magnetization and the inner magnetic ring 14b for upper vertical magnetization are located above the diaphragm, the outer magnetic ring 13 for lower vertical magnetization and the inner magnetic ring 14 for lower vertical magnetization are located below the diaphragm, and the upper vertical magnetization inner magnetic ring 14 is located below the diaphragm. The magnetic outer magnetic ring 13b and the upper vertically magnetized inner magnetic ring 14b are fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com