Liquid metal conductive paste and preparation method thereof, and electronic device

A liquid metal and conductive paste technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, electrical components, cables/conductors, etc., can solve the problems of pollution efficiency, operator injury, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

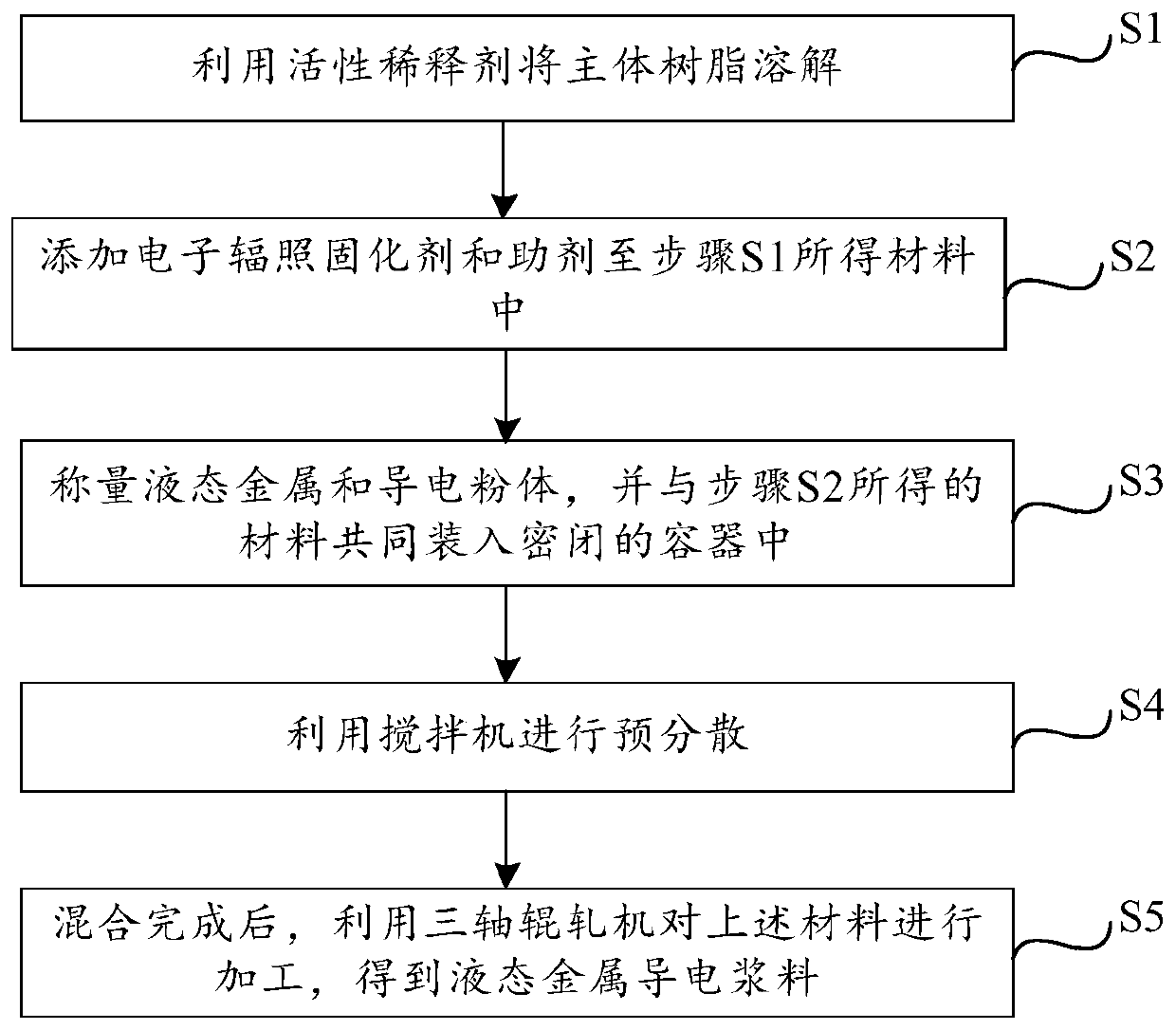

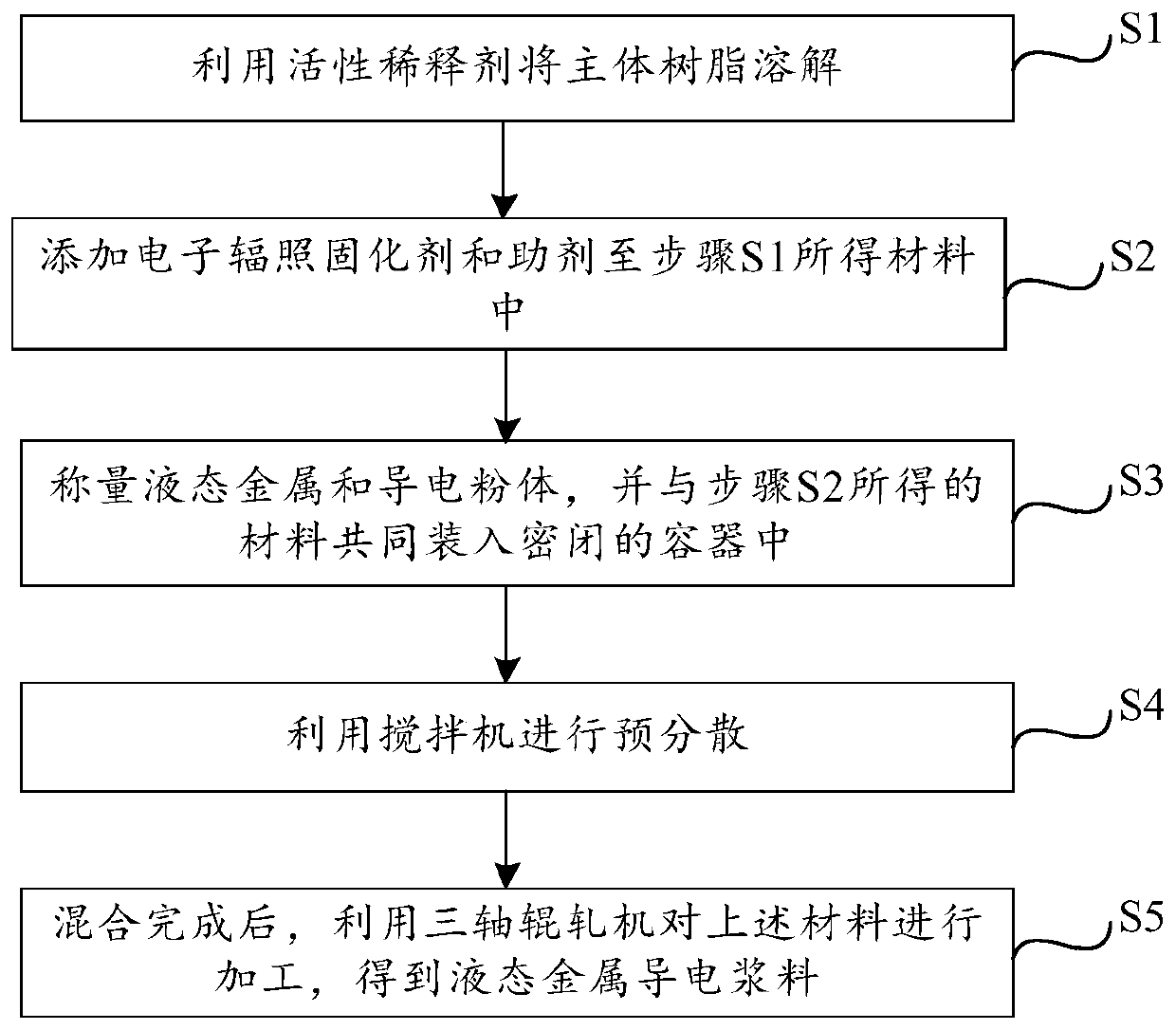

[0050] In addition, an embodiment of the present invention also provides a method for preparing a liquid metal conductive paste, which is used to manufacture the liquid metal conductive paste described in any one of the above. Specifically, such as figure 2 as shown, figure 2 The flow chart of the preparation method of the liquid metal conductive paste provided by the embodiment of the present invention, the preparation method of the liquid metal conductive paste includes:

[0051] Step S1, dissolving the main resin with a reactive diluent.

[0052] It should be noted that, when the liquid metal conductive paste also includes additives, the additives can be added after the main resin is dissolved in step S1, and then step S2 is performed.

[0053] Step S2, adding electron radiation curing agent and auxiliary agent to the material obtained in step S1.

[0054] Step S3, weighing the liquid metal and the conductive filler, and putting them into a closed container together wi...

Embodiment 1

[0077] Liquid metal conductive paste:

[0078] composition Types of Dosage (g) Main resin Polyurethane Modified Acrylic Resin 3 Conductive filler flake silver powder 12 liquid metal Gallium Indium Tin Eutectic Alloy 6 Active diluent Methyl methacrylate 5 Electronic Radiation Curing Agent Hexylene glycol diacrylate 3 Defoamer BYK028 0.5

Embodiment 2

[0080] Liquid metal conductive paste:

[0081]

[0082] The test initial resistance and bending resistance data of the conductive circuit made of the liquid metal conductive paste in embodiment 1 and embodiment 2, and the test initial resistance and bending resistance data of the conductive circuit made of traditional rolled copper foil are as follows (each The difference between the conductive lines is only that the materials are different, and other parameters such as length, width, and thickness are the same. for 200mm):

[0083] Example 1 Example 2 Calendered Copper Foil initial resistance 6.7,6.7 7.2,7.4 0.3 10,000 times 7.0,6.9 7.4,7.6 0.6 20,000 times 6.8,6.8 7.3,7.6 2.8 30,000 times 6.9,6.8 7.6,7.7 11.8 40,000 times 6.9,6.9 7.7,7.7 82.6 50,000 times 7.0,7.1 7.6,7.7 85.4 60,000 times 6.9,6.9 7.7,7.7 90.8 70,000 times 7.1,7.2 7.6,7.7 fracture 80,000 times 7.0,7.1 7.6,7.7 fracture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com