Atomization device for preparing alloy metal powder

A metal powder and atomization device technology, which is applied in metal processing equipment, transportation and packaging, chemical instruments and methods, etc., can solve the problems of blockage of the powder feeding system for conveying alloy powder, great difference in melting point, uneven powder feeding, etc. To achieve the effect of reducing the bonding phenomenon between powders, realizing modification and passivation, and achieving significant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

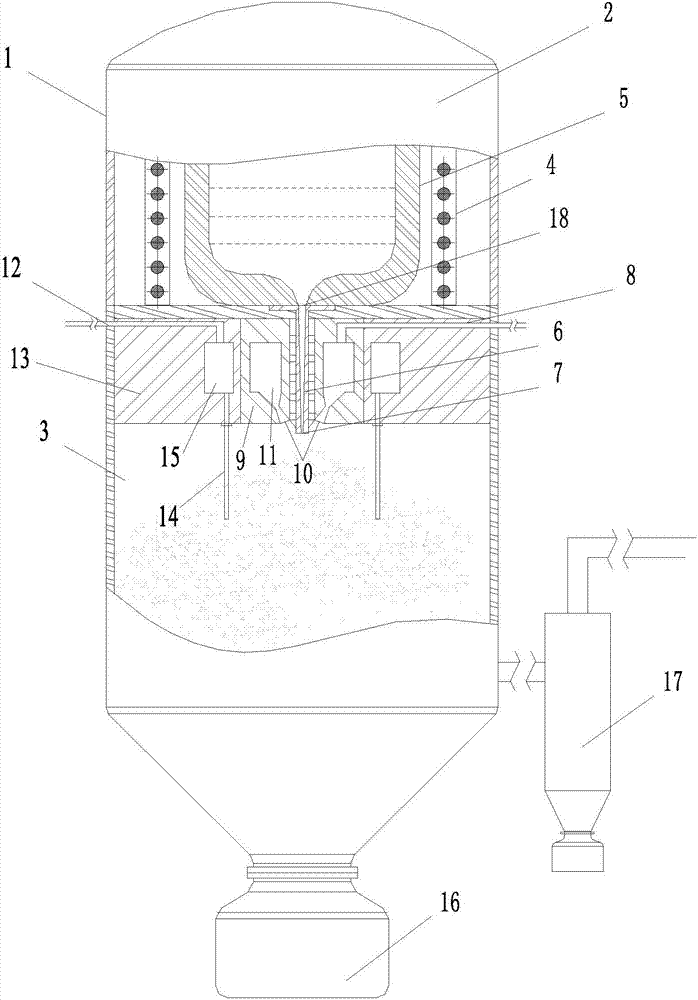

[0034] Such as figure 1 As shown, an atomization device for preparing alloy metal powder includes a main body 1. The main body 1 has a cylindrical tower body and a conical bottom. The main body 1 is sequentially provided with a vacuum melting chamber 2 and an atomizing chamber from top to bottom. 3. The vacuum melting chamber 2 is set directly above the atomization chamber 3, and is separated by a plate between the vacuum melting chamber 2 and the atomization chamber 3. The vacuum melting chamber 2 is provided with a melting device 5 and a heating device 4, In this embodiment, the melting device 5 is a crucible, and the heating device 4 is arranged around the melting device 5. The heating device 4 can heat the melting device 5, and can heat the temperature in the melting device 5 to make the alloy in the melting device 5 The metal is all melted into alloy metal liquid, and a liquid outlet 18 is provided at the bottom of the melting device 5, and the liquid outlet 18 communicat...

Embodiment 2

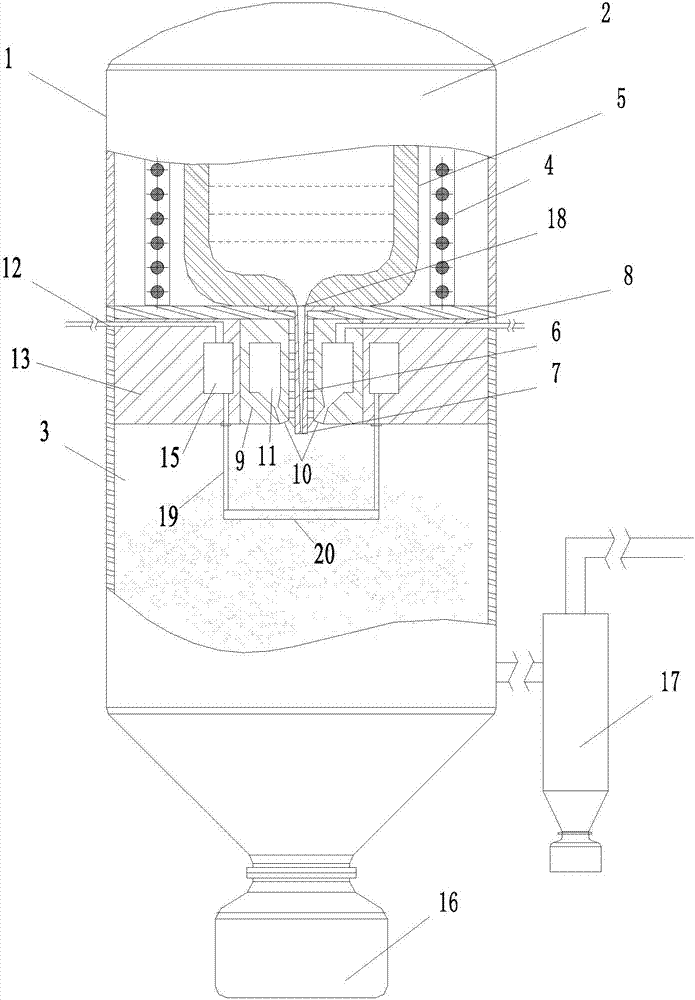

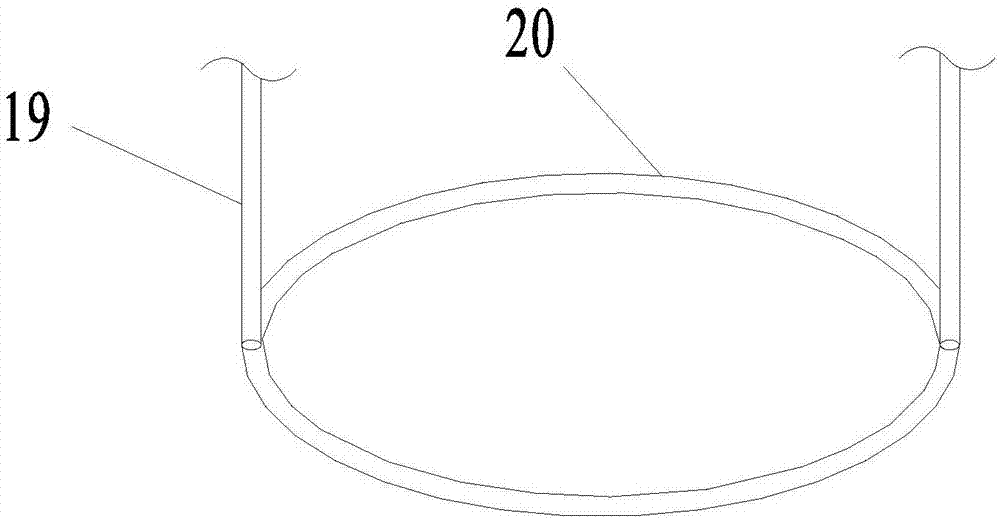

[0044] The difference between embodiment 2 and embodiment 1 is that, as figure 2 , image 3 with Figure 4 As shown, the air intake device 12 includes a connecting pipe 19 and an annular metal pipe 20, the connecting pipe 19 is vertically fixed on the top of the atomization chamber 3, the top of the connecting pipe 19 communicates with the buffer cavity 15 in the buffer disk 13, and the bottom of the connecting pipe 19 communicates with the buffer cavity 15 in the buffer disk 13. The end communicates with the annular metal pipe 20, and the bottom of the annular metal pipe 20 is provided with air injection holes, and the air injection holes are evenly spaced along the circumferential direction of the annular metal pipe 20; in the present embodiment, the air injection holes on the annular metal pipe 20 can be more effective. It is conducive to the uniform delivery and distribution of oxygen-containing gas in the atomization area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com