Preparation method of low-defect quasi-two-dimensional perovskite film based on methanesulfonic acid negative ion induction

An anionic, low-defect technology, applied in chemical instruments and methods, luminescent materials, photovoltaic power generation, etc., can solve problems such as grain growth obstruction and inefficiency, and achieve the effect of inhibiting non-radiative recombination and effective energy transfer paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, see figure 1 and figure 2 , a preparation technology based on methanesulfonic acid anion-induced low-defect quasi-two-dimensional perovskite film, including the following steps:

[0021] a. Quasi-two-dimensional BA 2 Cs n-1 Pb n Br 3n+1 Preparation of perovskite precursor solution:

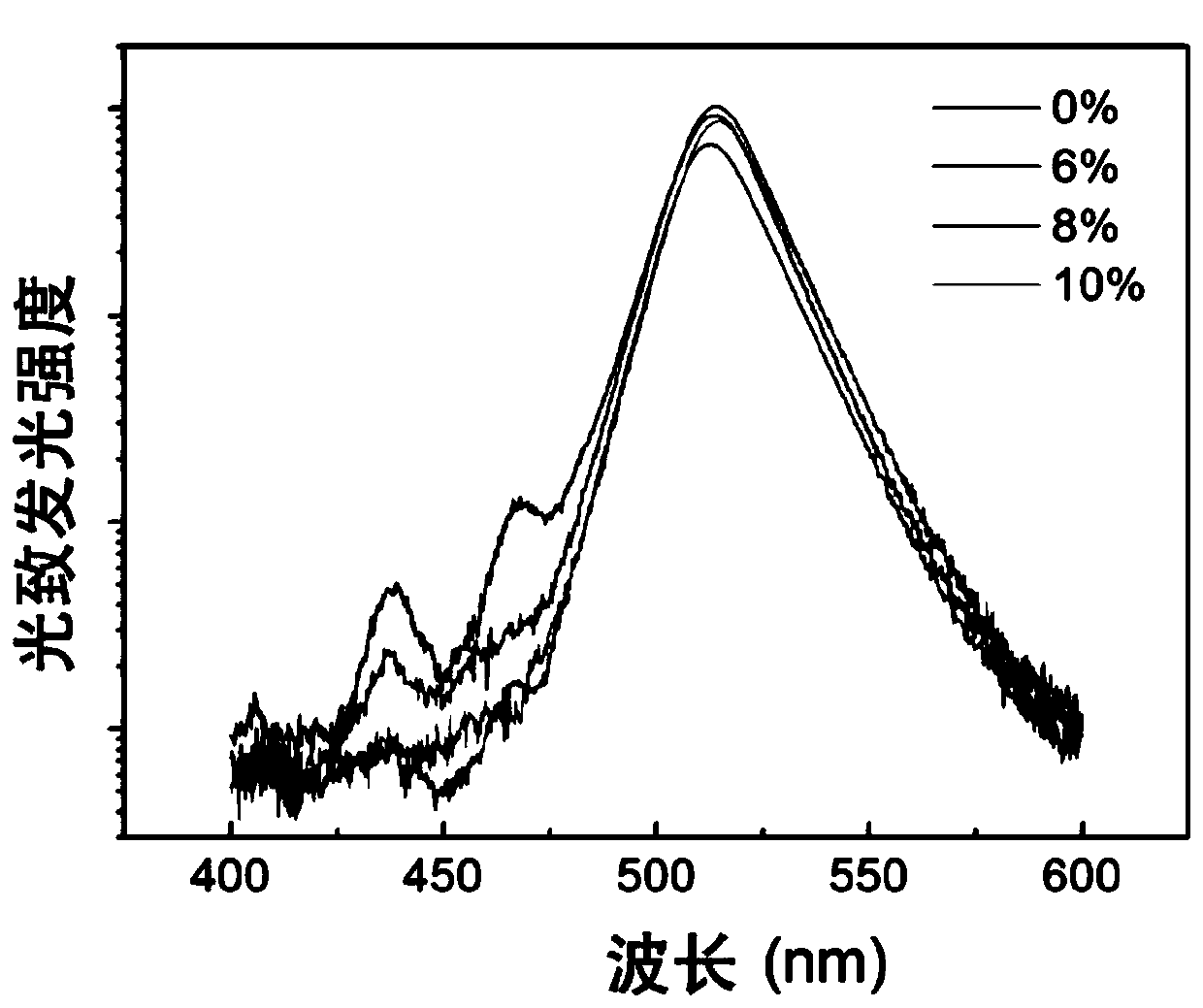

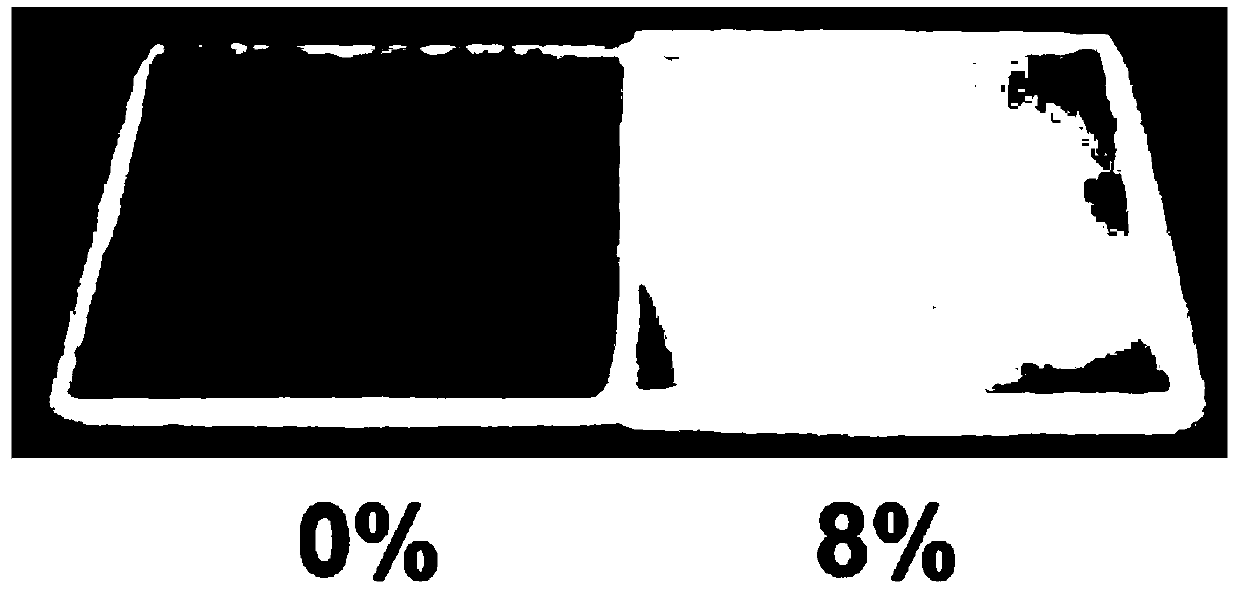

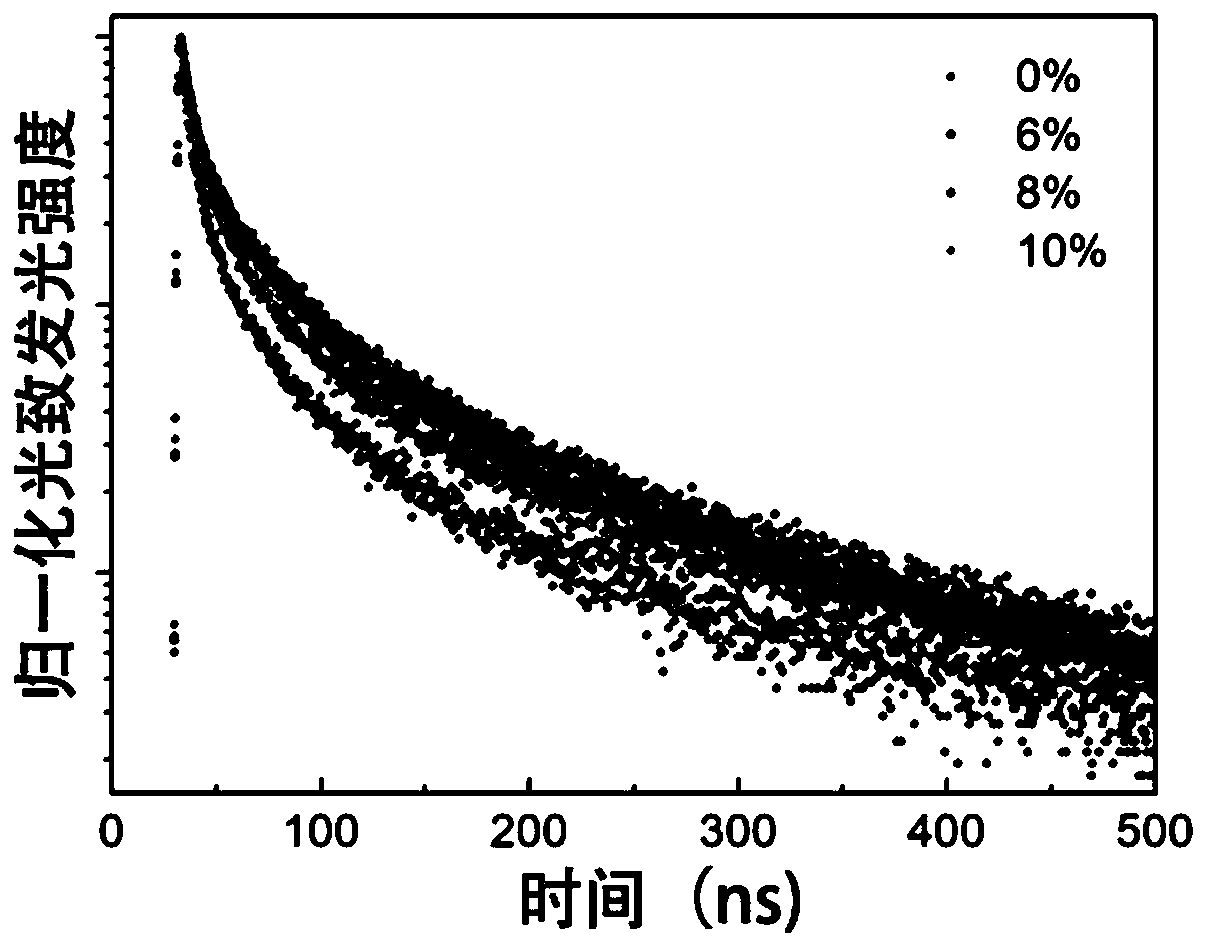

[0022] Weigh BABr, PbBr according to the molar ratio of 0.4:1:1.2 2 and CsBr, which were dissolved in anhydrous DMSO, were used as precursors of quasi-two-dimensional perovskites, where PEO was added at 3 wt% to improve the morphology of the film. On this basis, CsMeS was added to the precursor, which with PbBr 2 The molar ratios are 0%, 6%, 8% and 10%, respectively. Then, after heating at 80 °C for 10 min, BA was prepared on the substrate by one-step spin coating 2 Cs n-1 Pb n Br 3n+1 perovskite thin film. Filter all precursor solutions through a 0.45 μm polytetrafluoroethylene filter before use.

[0023] b. Quasi-two-dimensional BA 2 Cs n-1 Pb n Br 3n+1...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

[0030] In this embodiment, a preparation technology based on methanesulfonic acid anion-induced low-defect quasi-two-dimensional perovskite film includes the following steps:

[0031] a. Quasi-two-dimensional BA 2 Cs n-1 Pb n Cl 3n+1 Preparation of perovskite precursor solution:

[0032] Weigh BACl, PbCl according to the molar ratio of 0.4:1:1.2 2 and CsCl, which were dissolved in anhydrous DMSO, were used as precursors of quasi-two-dimensional perovskites, where PEO was added at 3 wt% to improve the morphology of the film. On this basis, CsMeS was added to the precursor, which with PbCl 2 The molar ratios are 0%, 6%, 8% and 10%, respectively. Then, after heating at 80 °C for 10 min, BA was prepared on the substrate by one-step spin coating 2 Cs n-1 Pb n Cl 3n+1 perovskite thin film. Filter all precursor solutions through a 0.45 μm polytetrafluoroethylene filter before use.

[0033...

Embodiment 3

[0039] This embodiment is basically the same as the aforementioned implementation, and the special features are:

[0040] In this embodiment, a preparation technology based on methanesulfonic acid anion-induced low-defect quasi-two-dimensional perovskite film includes the following steps:

[0041] a. Quasi-two-dimensional BA 2 Cs n-1 Pb n I 3n+1 Preparation of perovskite precursor solution:

[0042] Weigh BAI, PbI according to the molar ratio of 0.4:1:1.2 2 and CsI, which were dissolved in anhydrous DMSO, were used as precursors of quasi-two-dimensional perovskites, where PEO was added at 3 wt% to improve the morphology of the film. On this basis, CsMeS was added to the precursor, which with PbI 2 The molar ratios are 0%, 6%, 8% and 10%, respectively. Then, after heating at 80 °C for 10 min, BA was prepared on the substrate by one-step spin coating 2 Cs n-1 Pb n I 3n+1 perovskite thin film. Filter all precursor solutions through a 0.45 μm polytetrafluoroethylene fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com