Patents

Literature

57 results about "Non-radiative recombination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

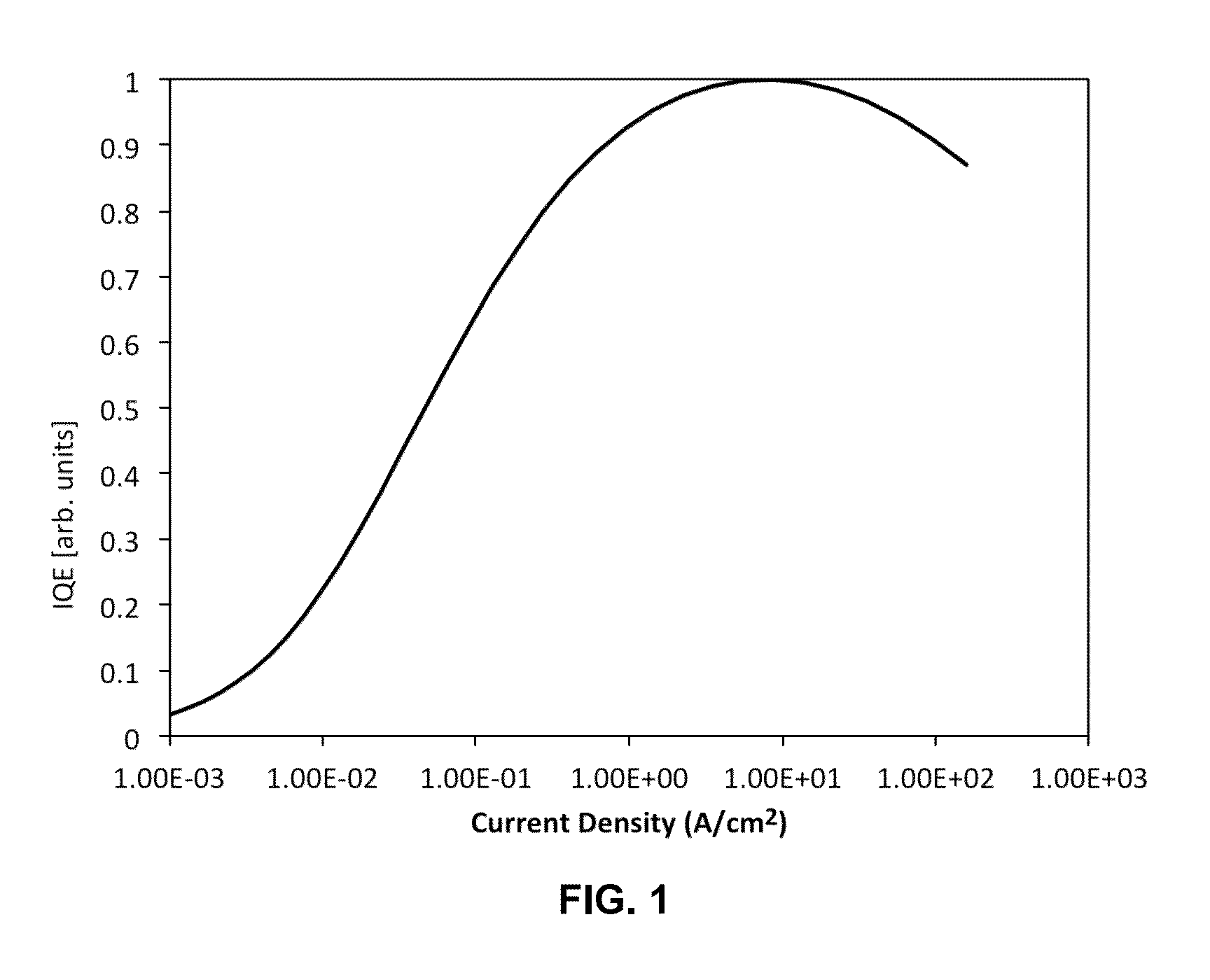

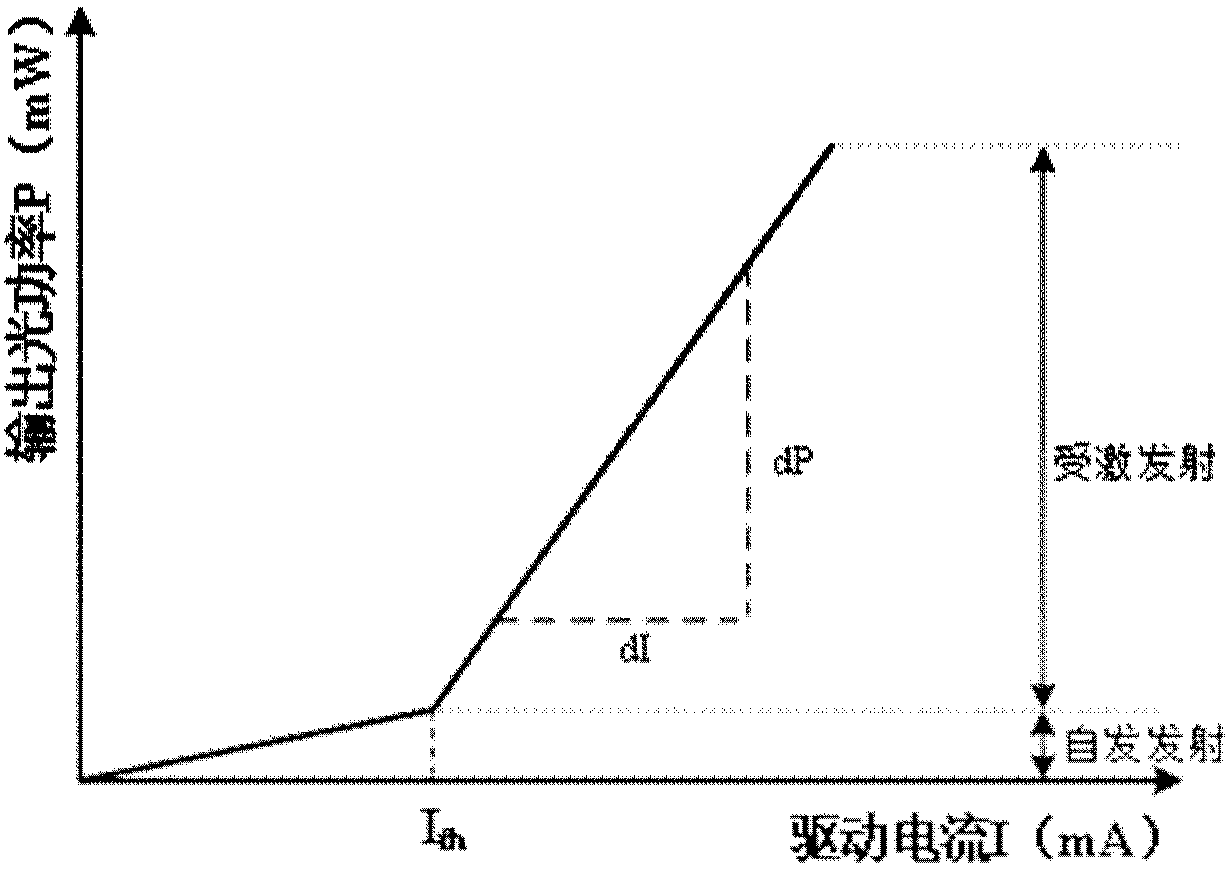

Non-radiative recombination is a process in phosphors and semiconductors, whereby charge carriers recombine without releasing photons. A phonon is released instead. Non-radiative recombination in optoelectronics and phosphors is an unwanted process, lowering the light generation efficiency and increasing heat losses.

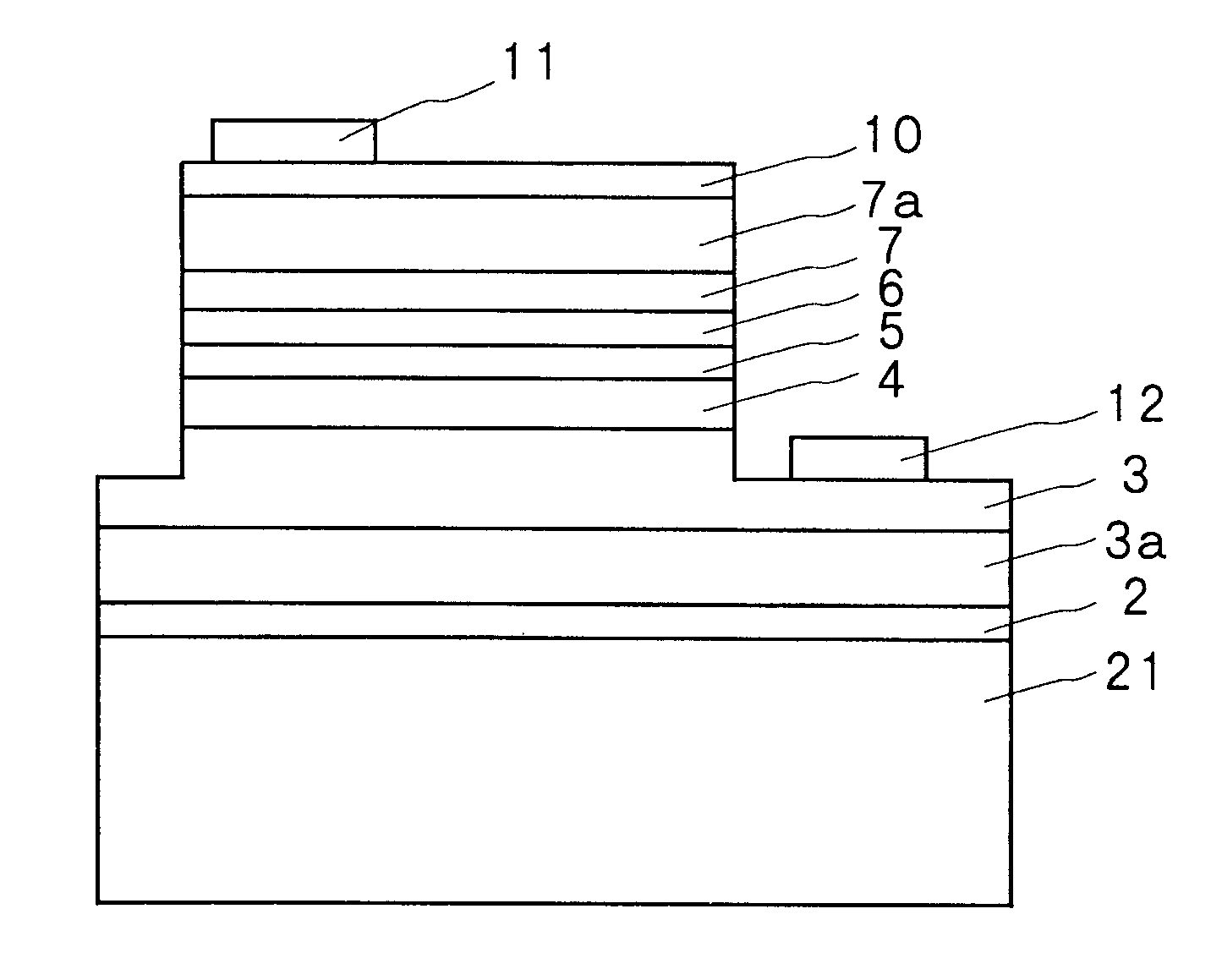

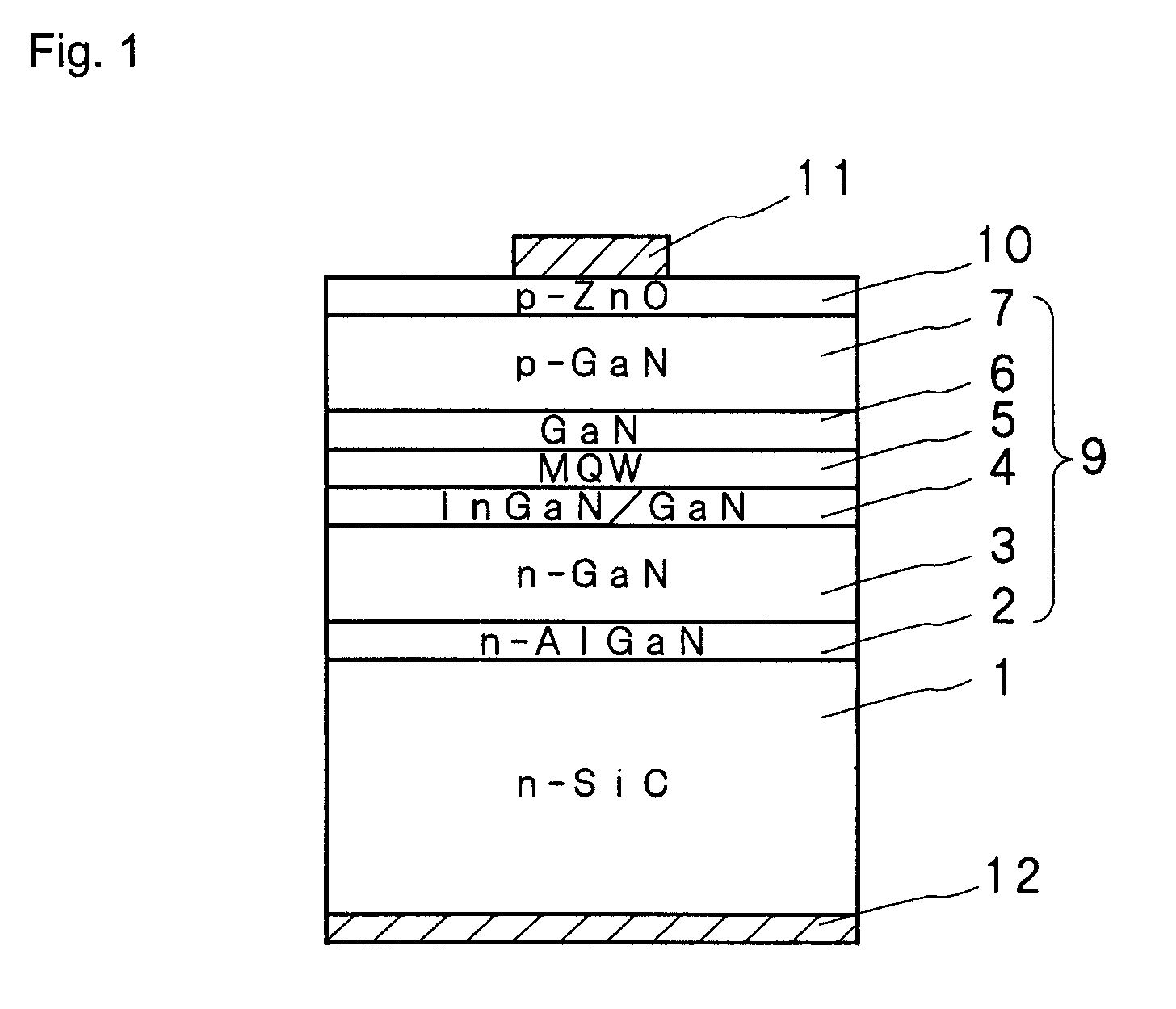

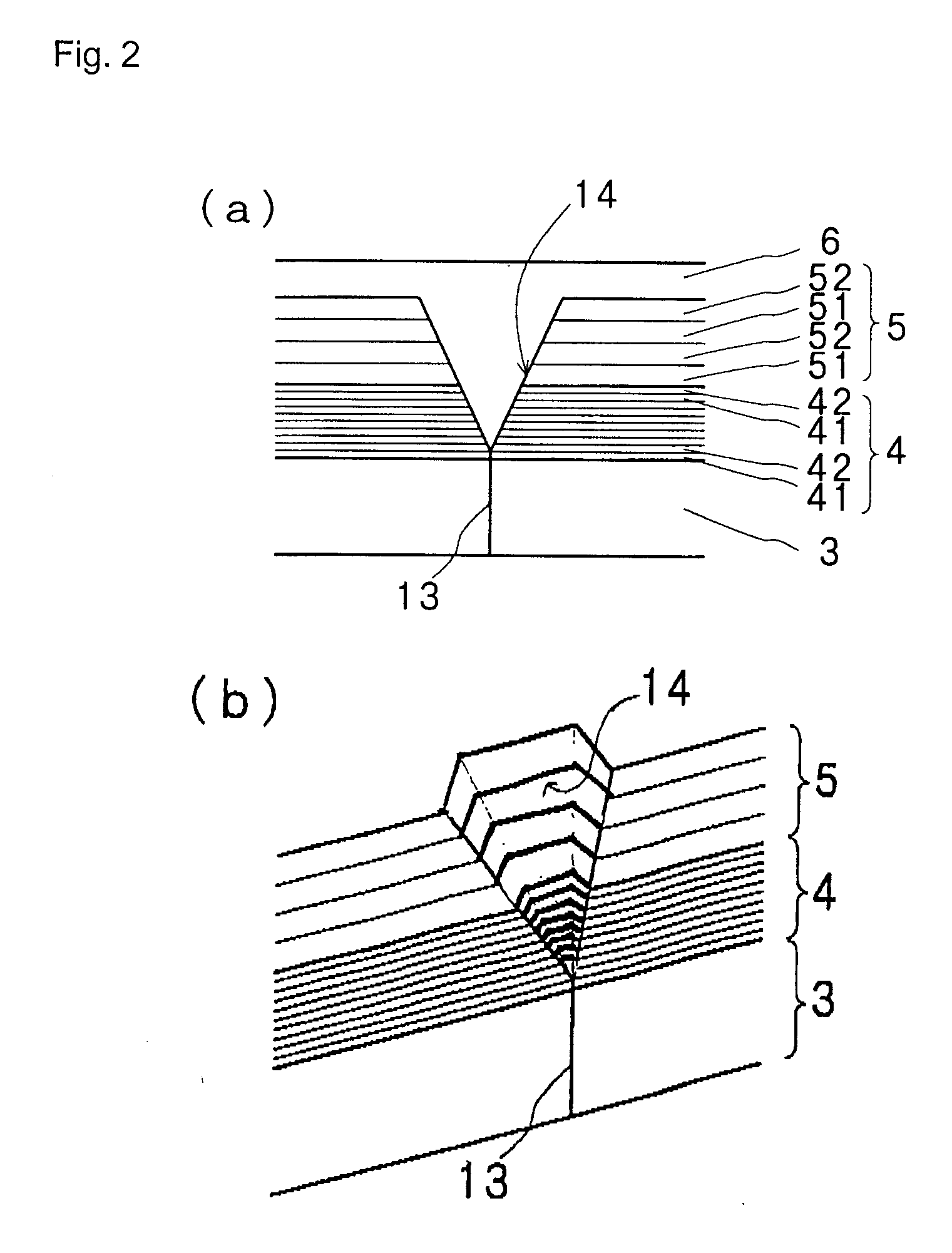

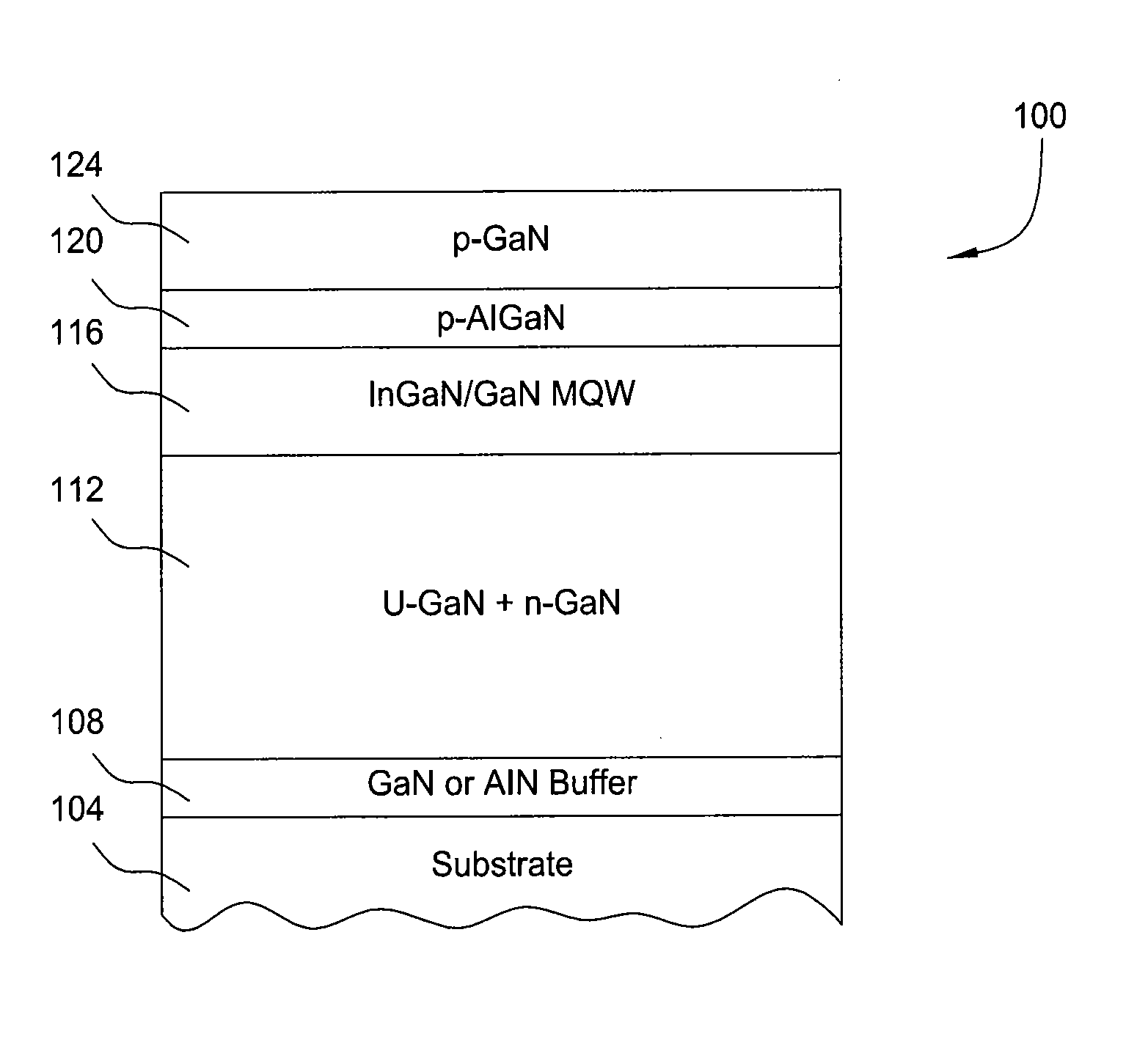

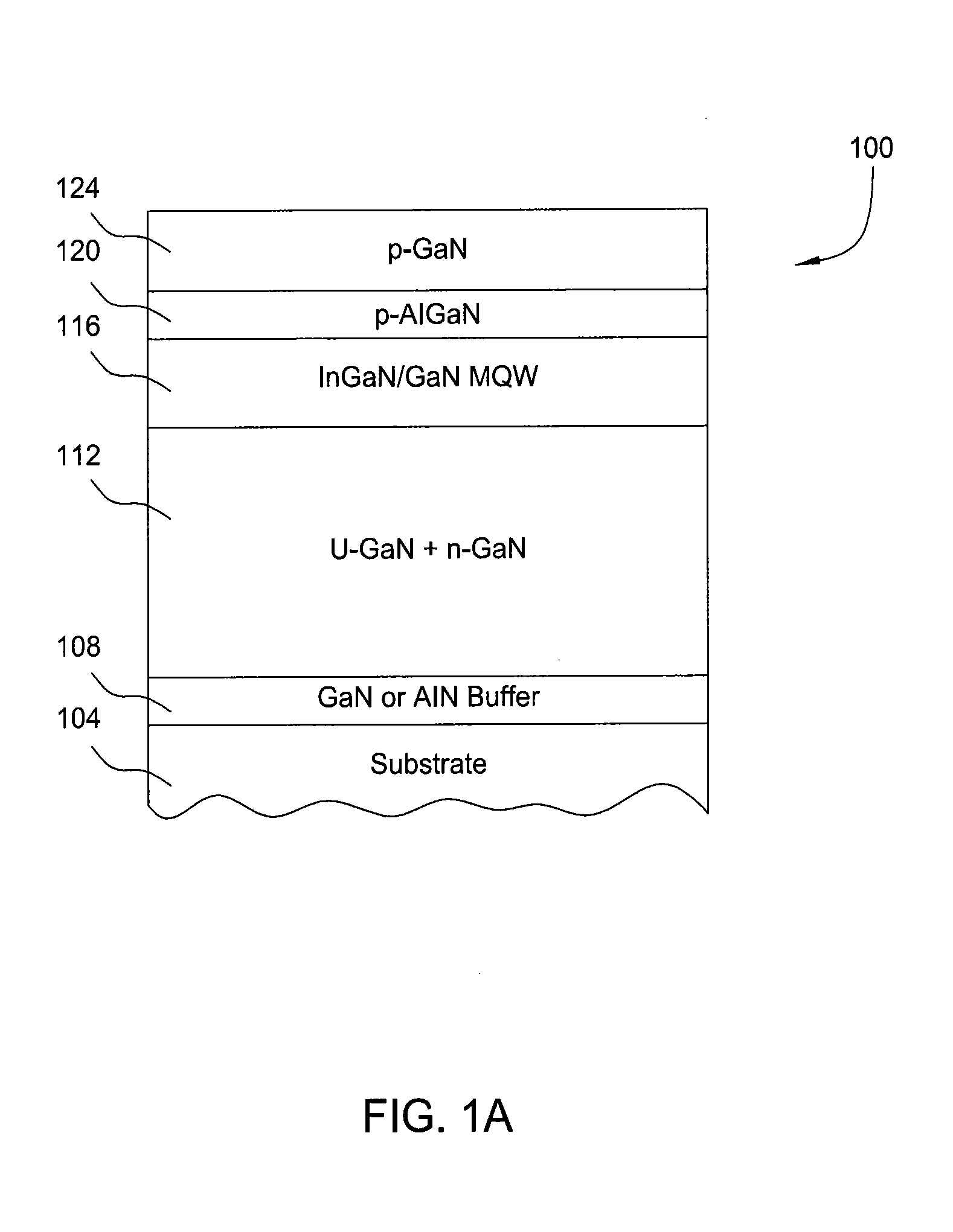

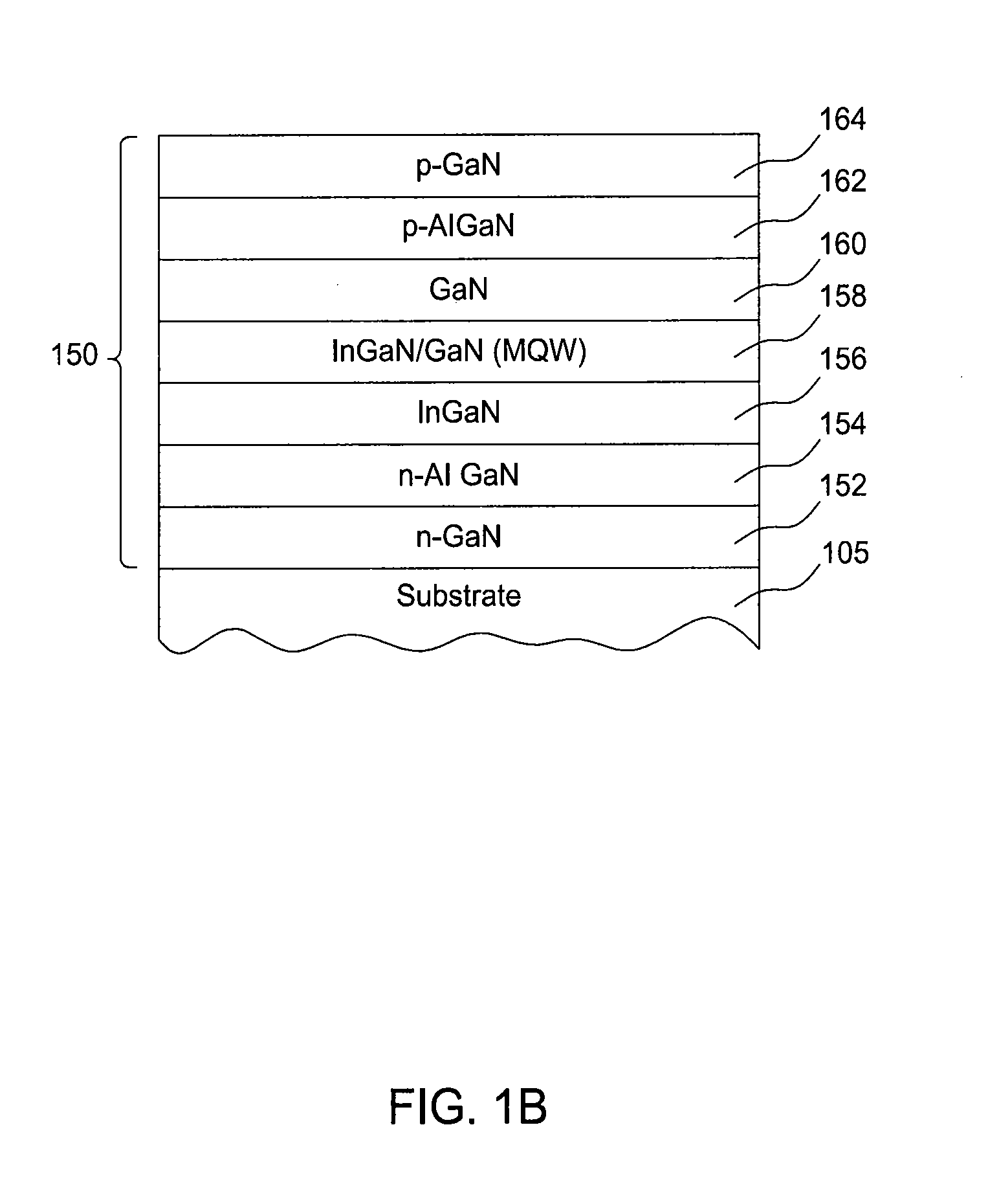

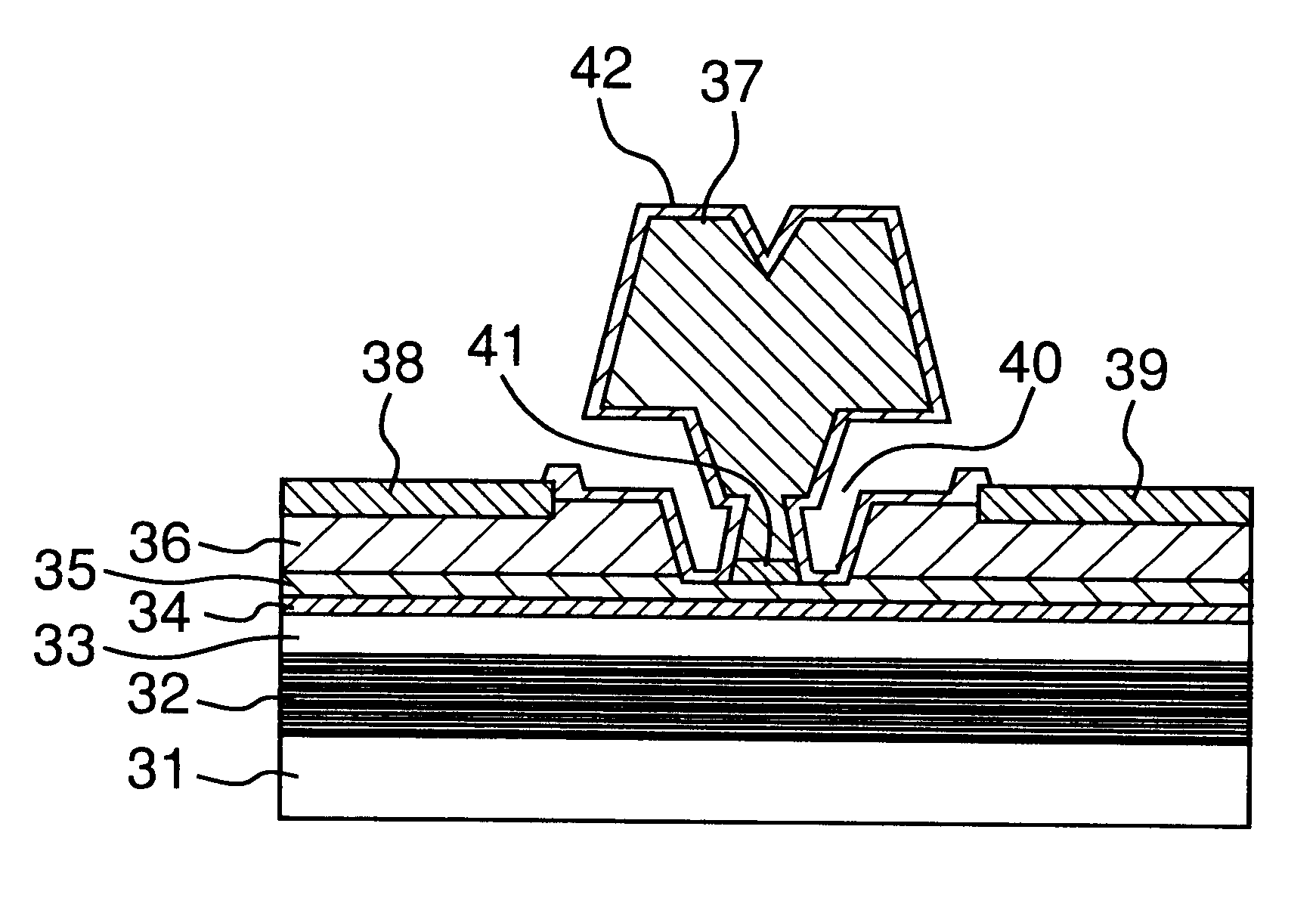

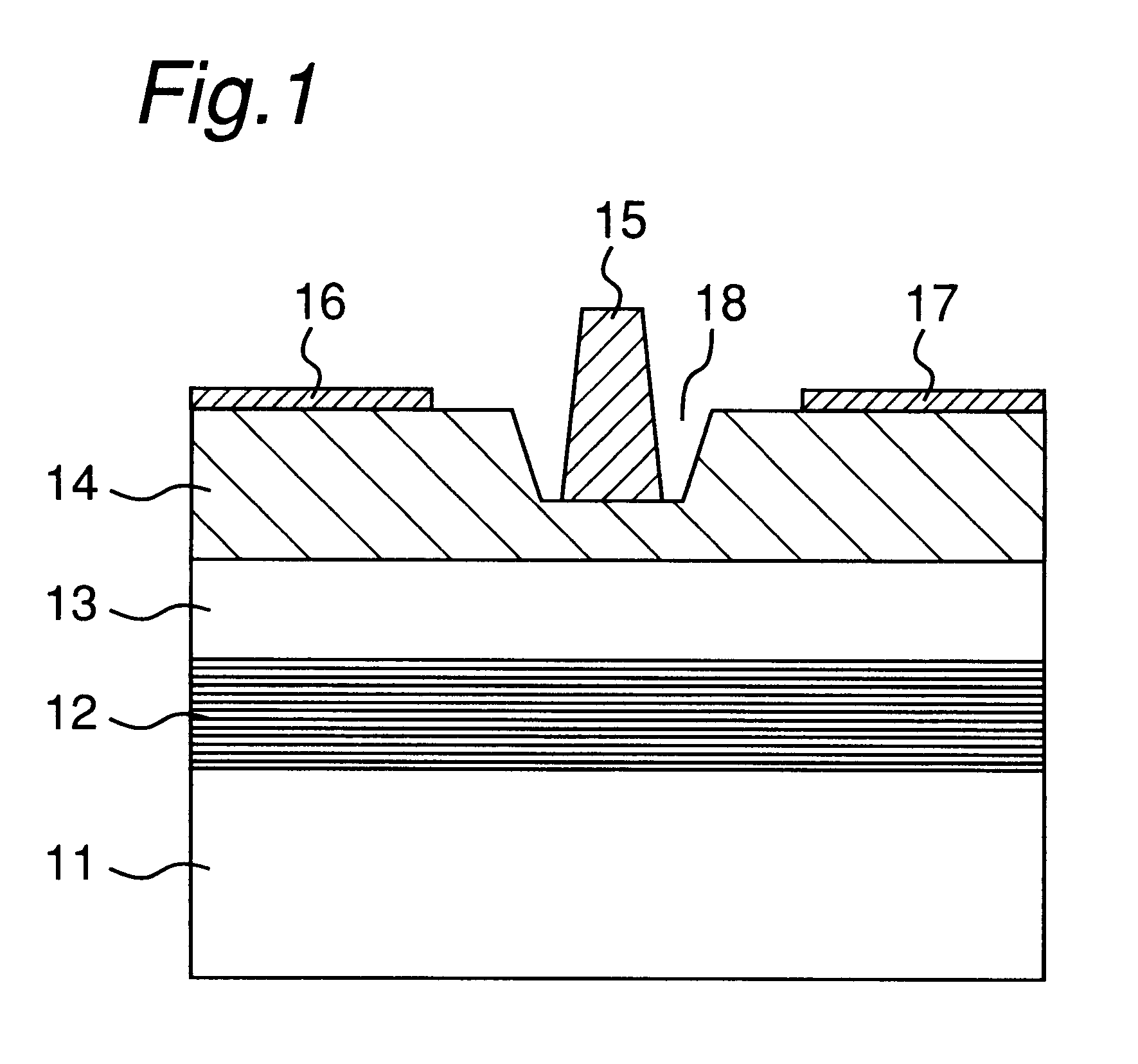

Nitride semiconductor light emitting element

InactiveUS20070122994A1Suppresses minimizesImprove film qualityLaser detailsSolid-state devicesThreading dislocationsQuantum efficiency

A nitride semiconductor light-emitting element suppresses leakage currents and non-radiative recombination centers by providing, as an underlying layer of the active layer, a pit formation layer that reliably generates pits, while maintaining a good film quality, so that the internal quantum efficiency is improved, and the light-emitting characteristics are also improved. A nitride semiconductor lamination portion including at least an active layer for forming a light-emitting portion is present on a substrate, and a pit formation layer is formed as a superlattice layer of nitride semiconductor on the side of the substrate of the active layer. The pit formation layer generates pits in the end portions of threading dislocations that are generated in the nitride semiconductor layer on the side of the substrate.

Owner:ROHM CO LTD

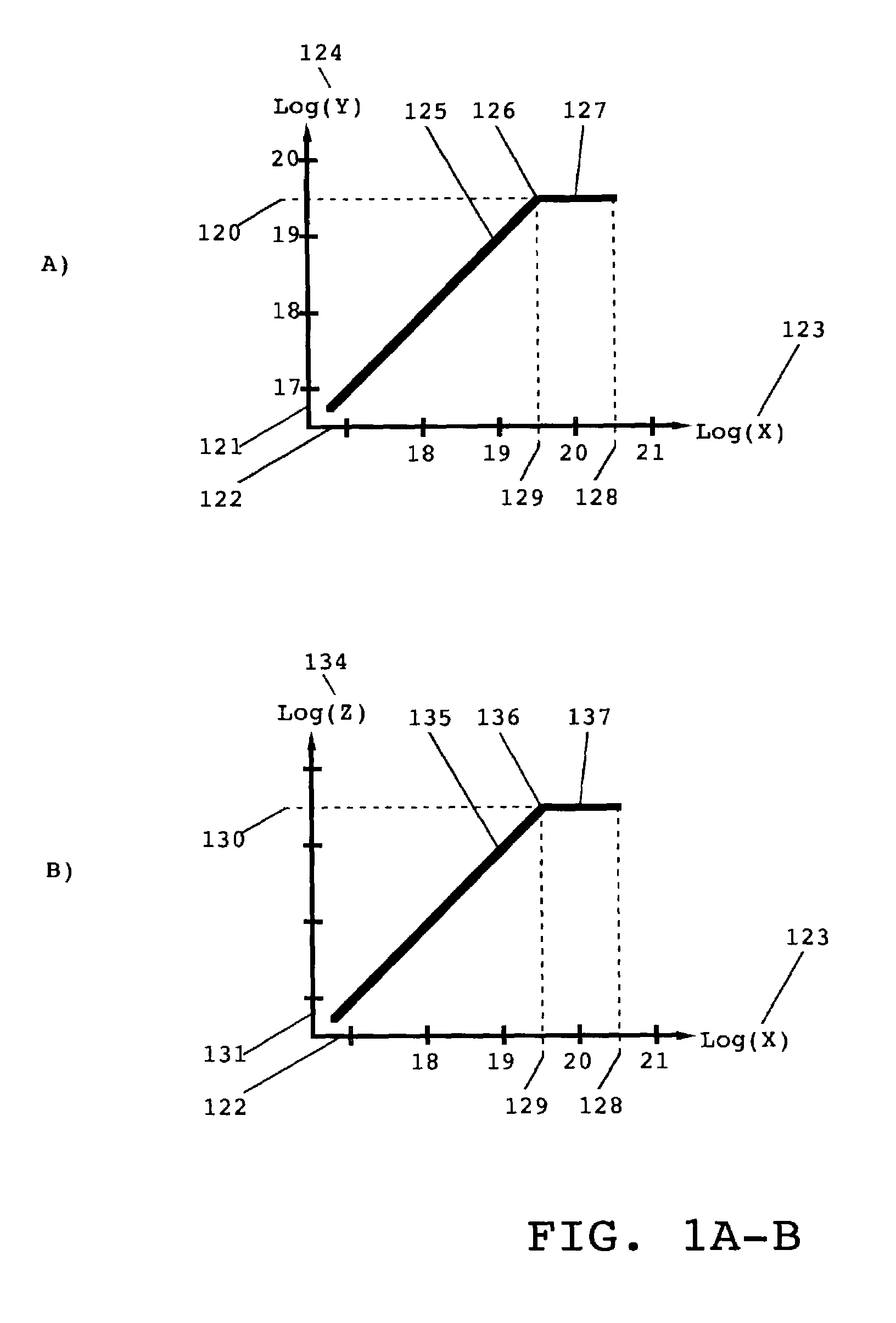

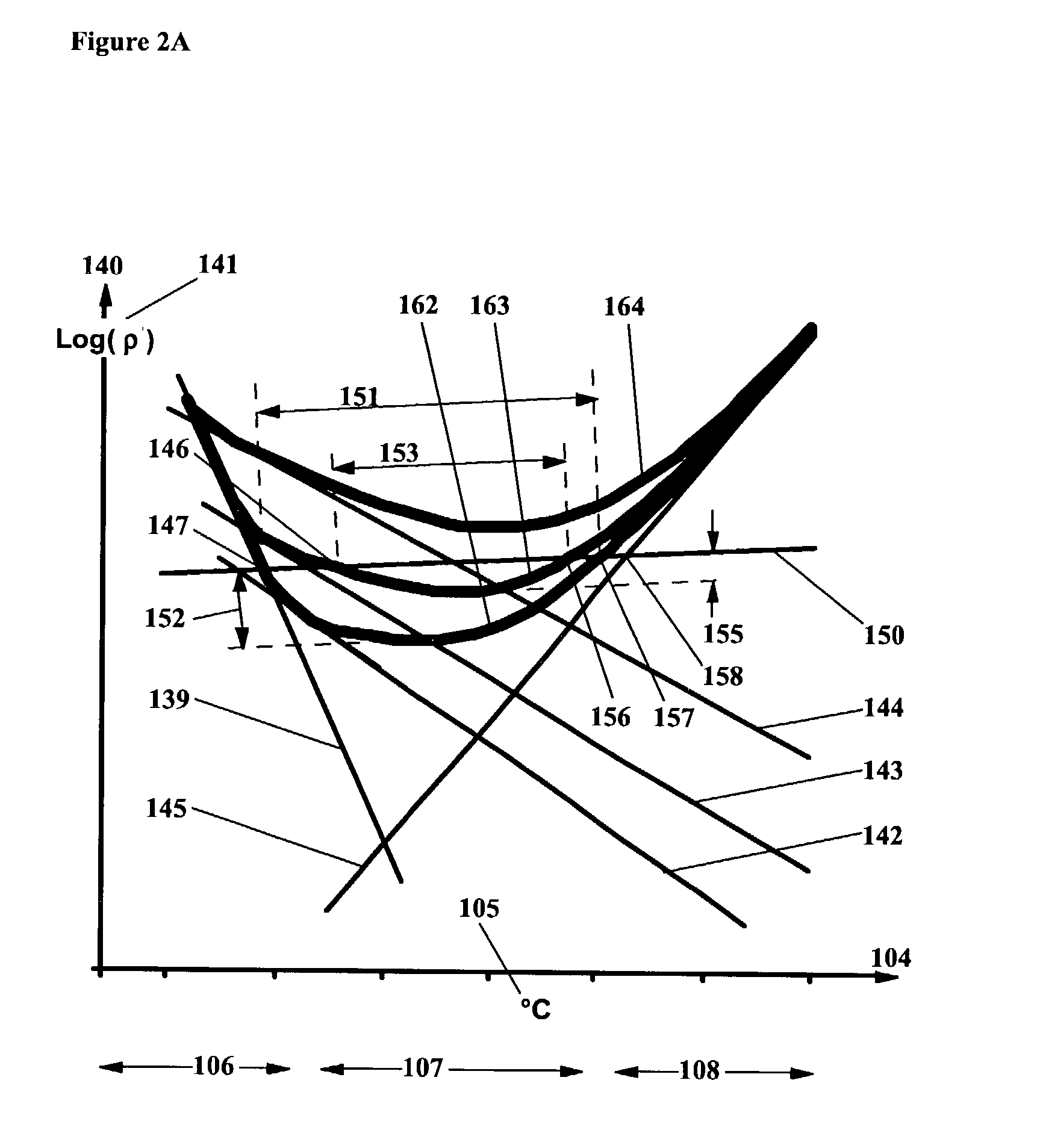

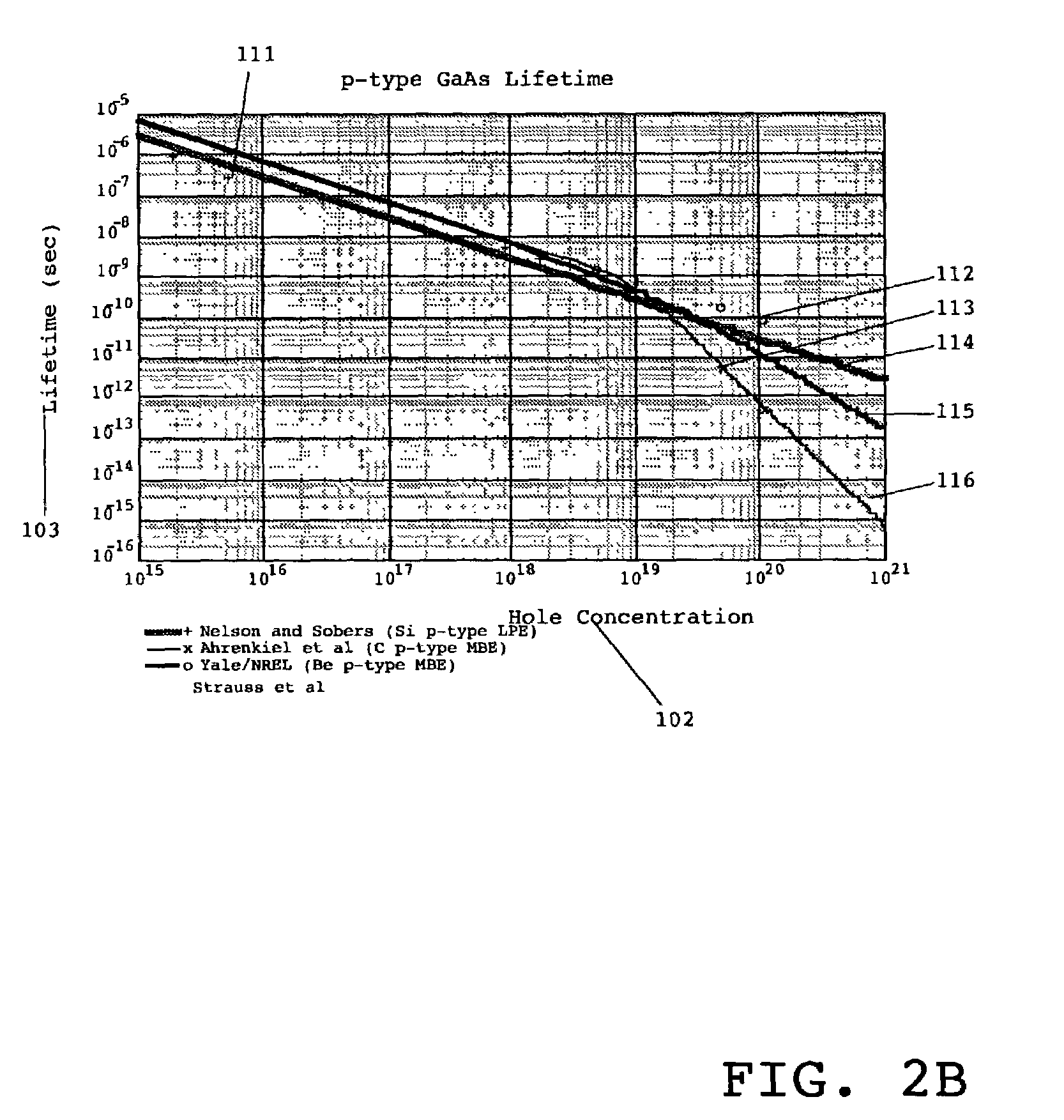

Methods of hyperdoping semiconductor materials and hyperdoped semiconductor materials and devices

InactiveUS20030121468A1Avoiding and mitigating formationEasy to operateTransistorPolycrystalline material growthSide effectSemiconductor materials

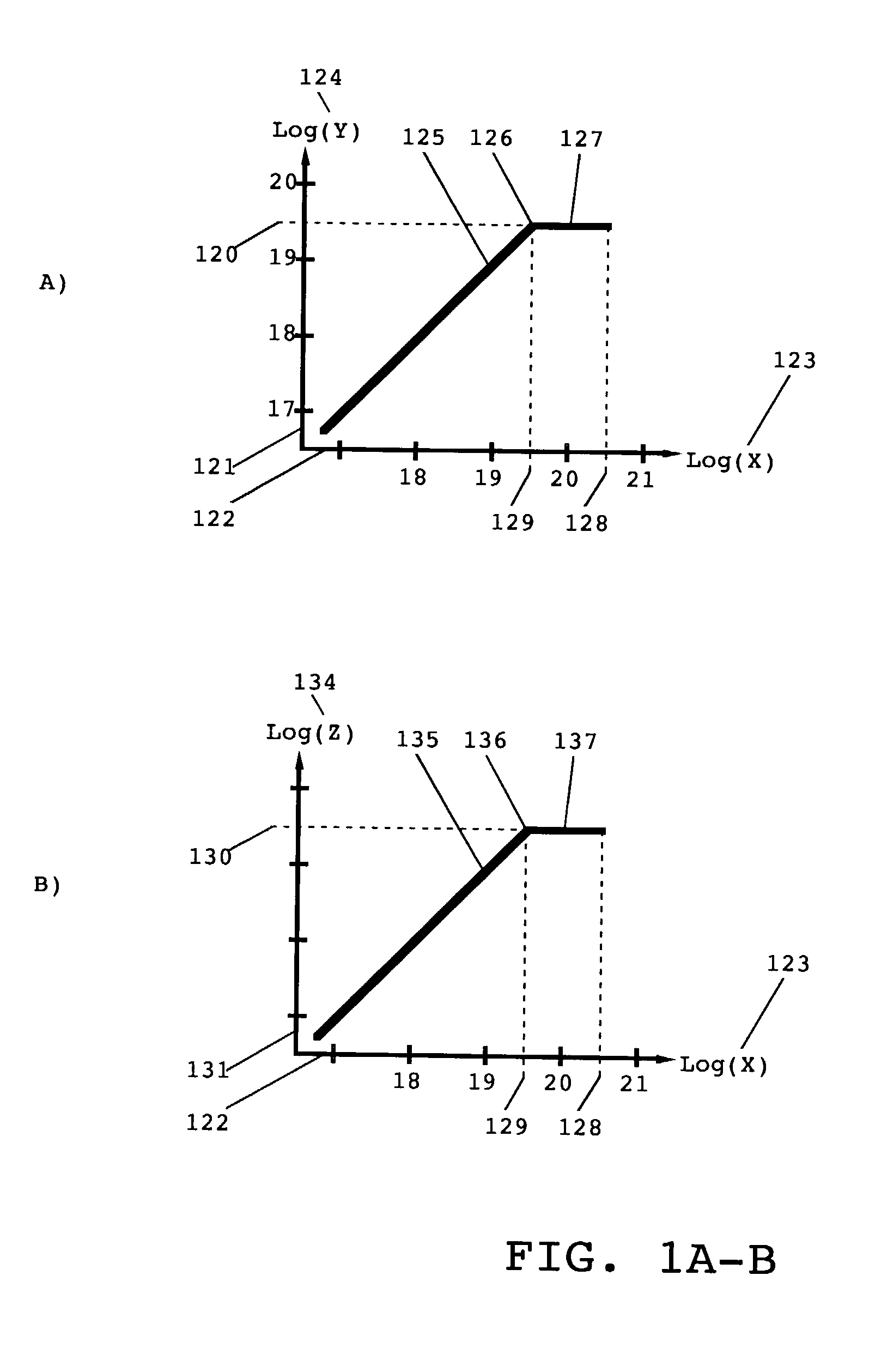

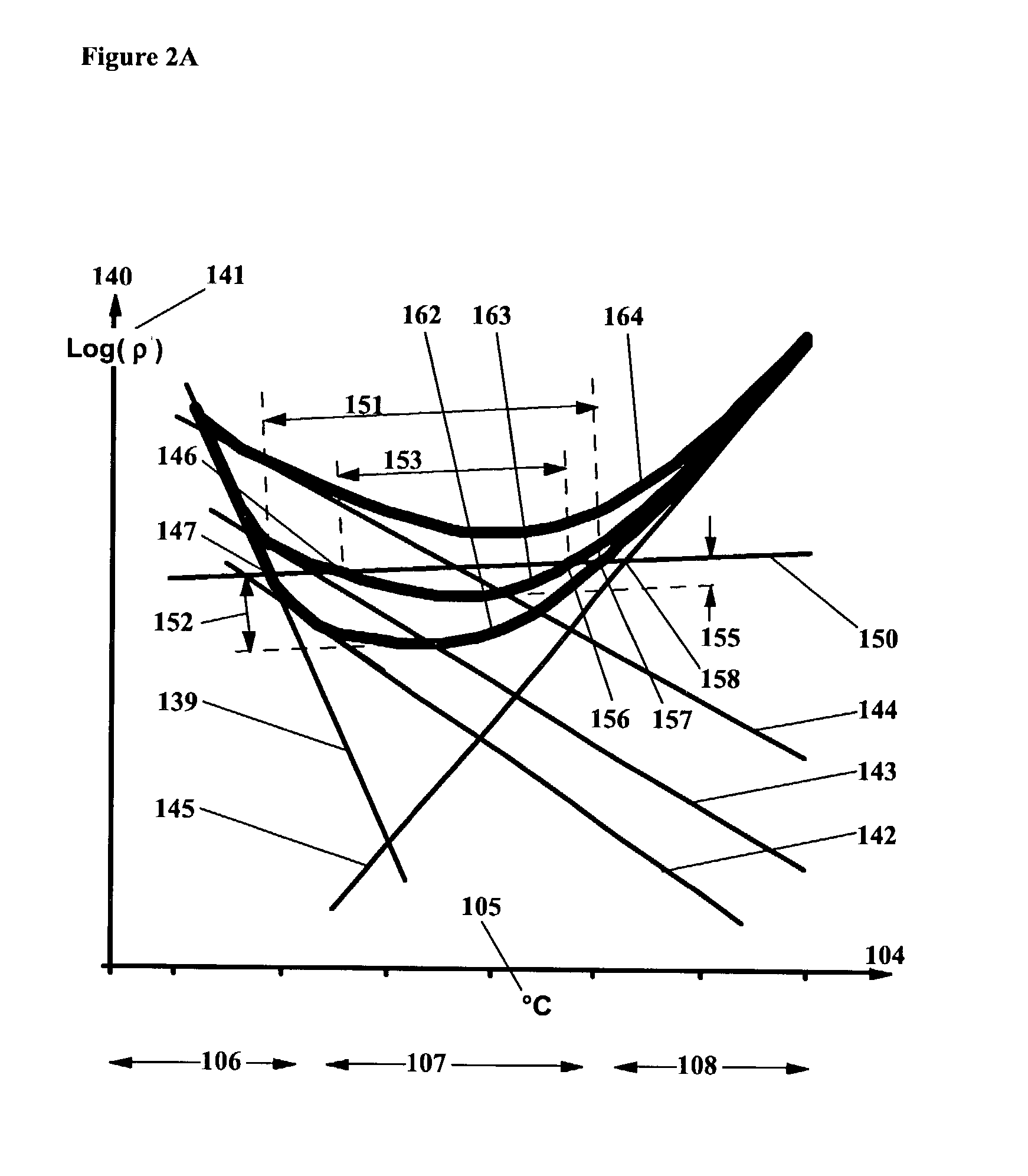

Methods are disclosed for producing highly doped semiconductor materials. Using the invention, one can achieve doping densities that exceed traditional, established carrier saturation limits without deleterious side effects. Additionally, highly doped semiconductor materials are disclosed, as well as improved electronic and optoelectronic devices / components using said materials. The innovative materials and processes enabled by the invention yield significant performance improvements and / or cost reductions for a wide variety of semiconductor-based microelectronic and optoelectronic devices / systems. Materials are grown in an anion-rich environment, which, in the preferred embodiment, are produced by moderate substrate temperatures during growth in an oxygen-poor environment. The materials exhibit fewer non-radiative recombination centers at higher doping concentrations than prior art materials, and the highly doped state of matter can exhibit a minority carrier lifetime dominated by radiative recombination at higher doping levels and higher majority carrier concentrations than achieved in prior art materials. Important applications enabled by these novel materials include high performance electronic or optoelectronic devices, which can be smaller and faster, yet still capture or emit light efficiently, and high performance electronics, such as transistors, which can be smaller and faster, yet cooler.

Owner:YALE UNIV

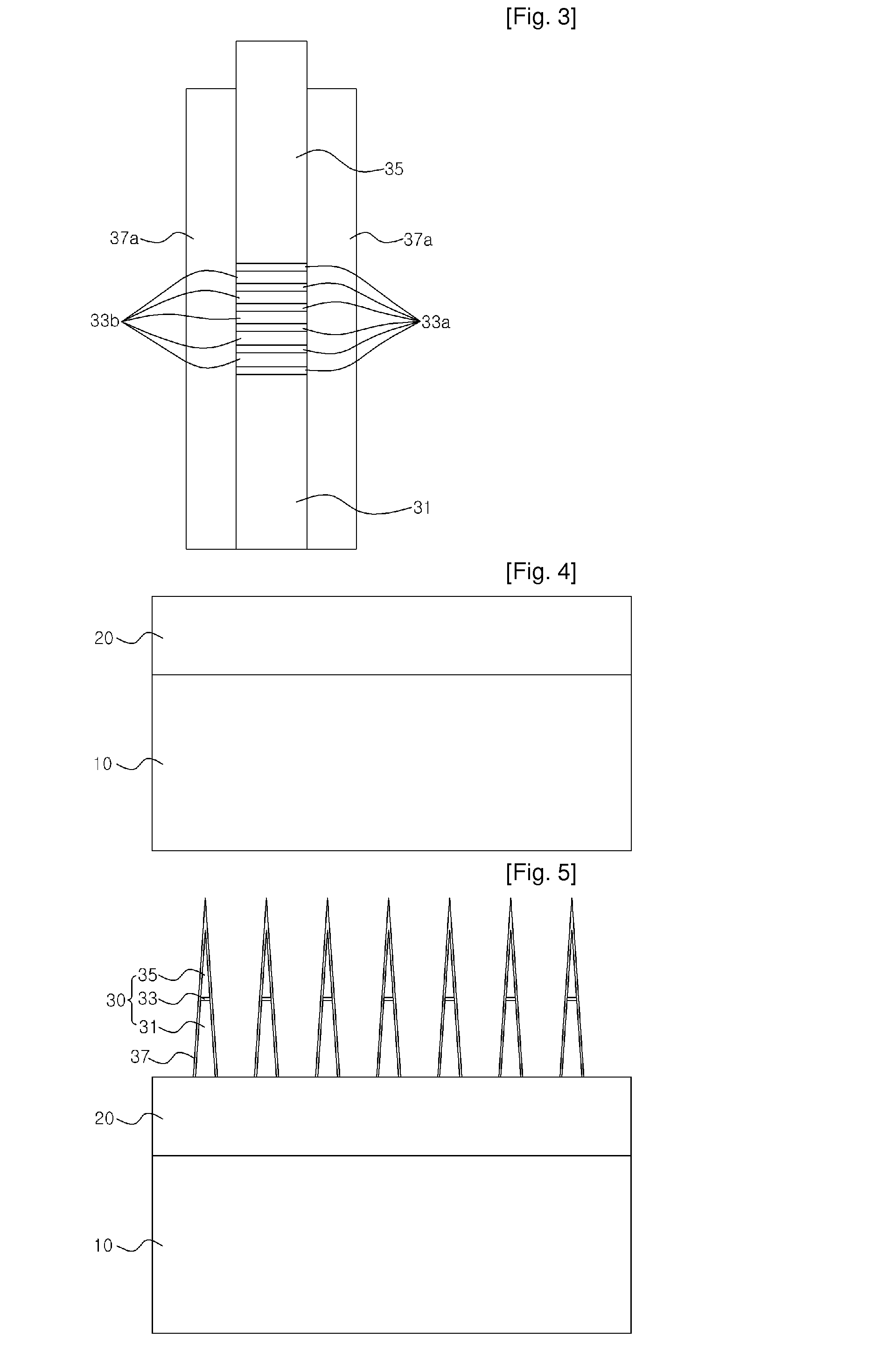

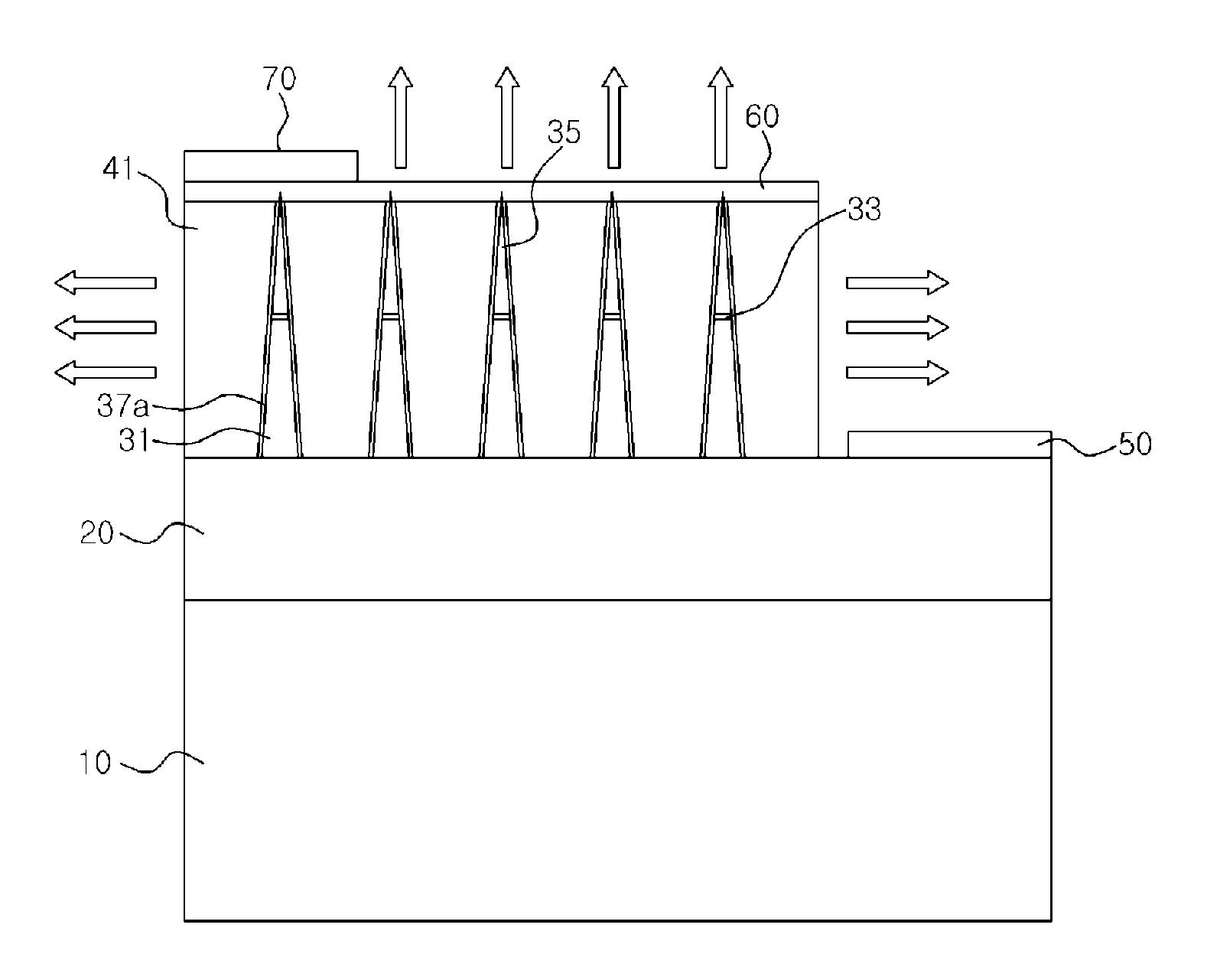

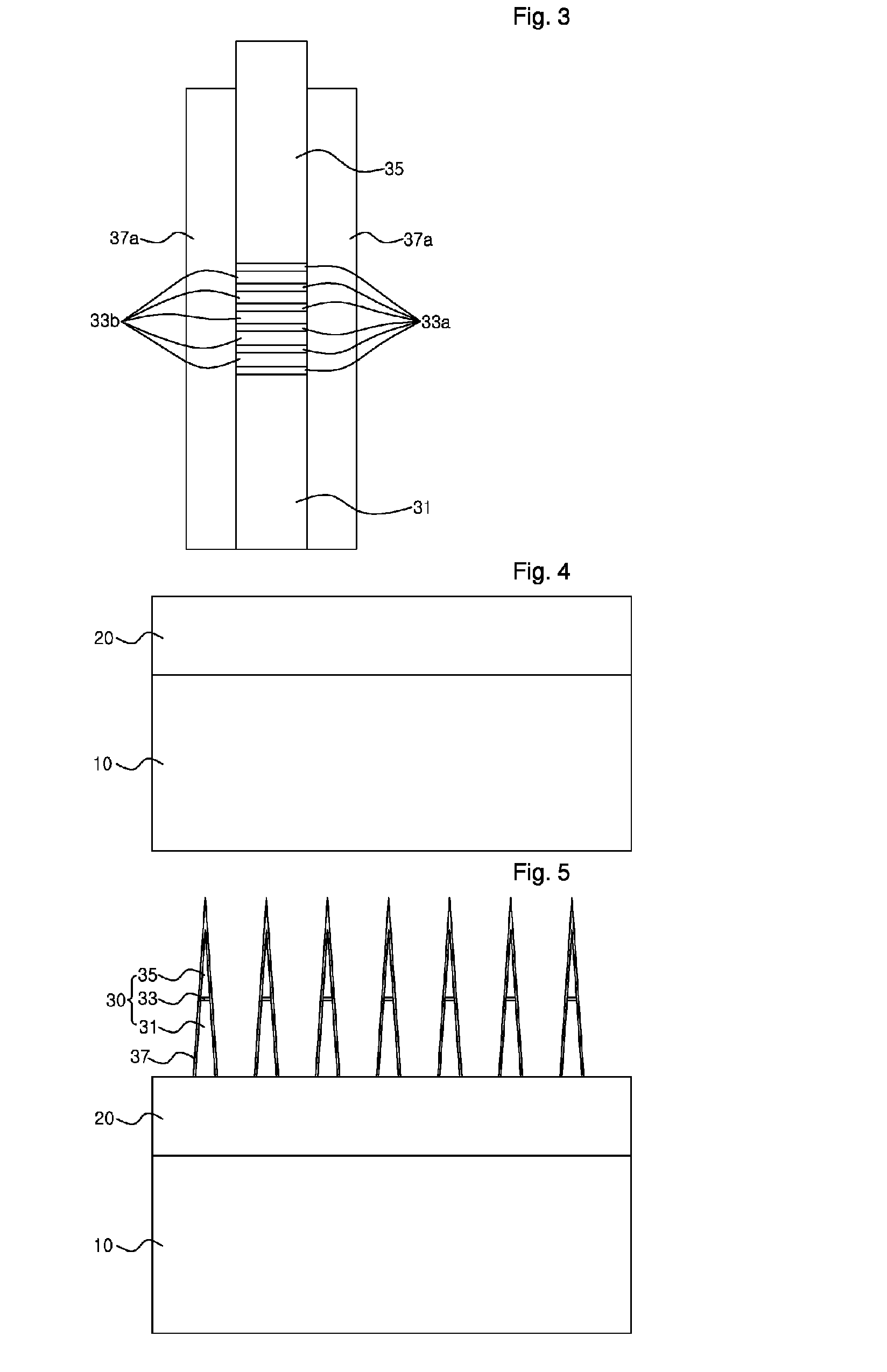

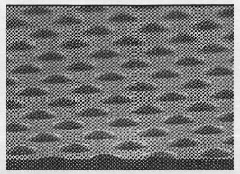

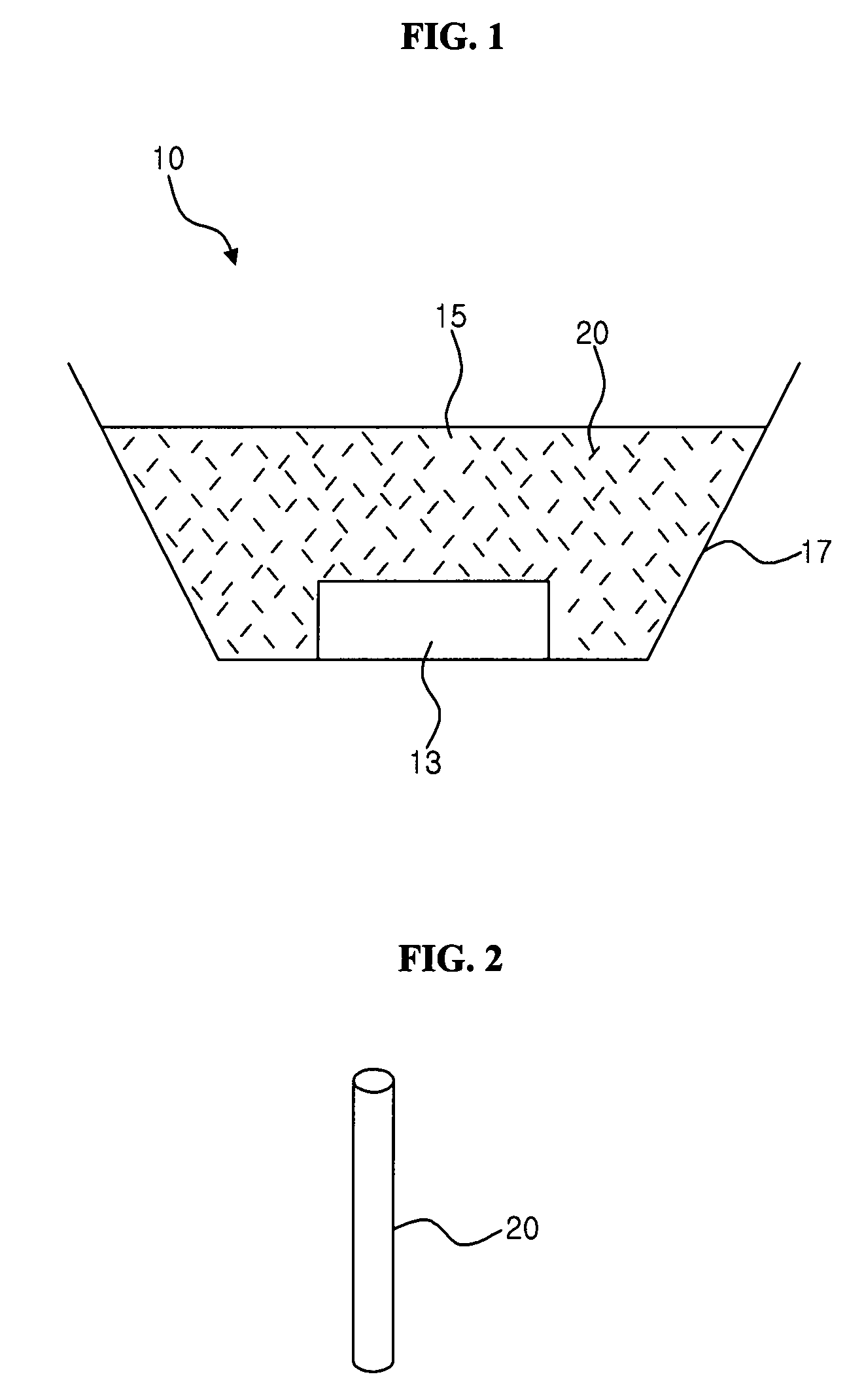

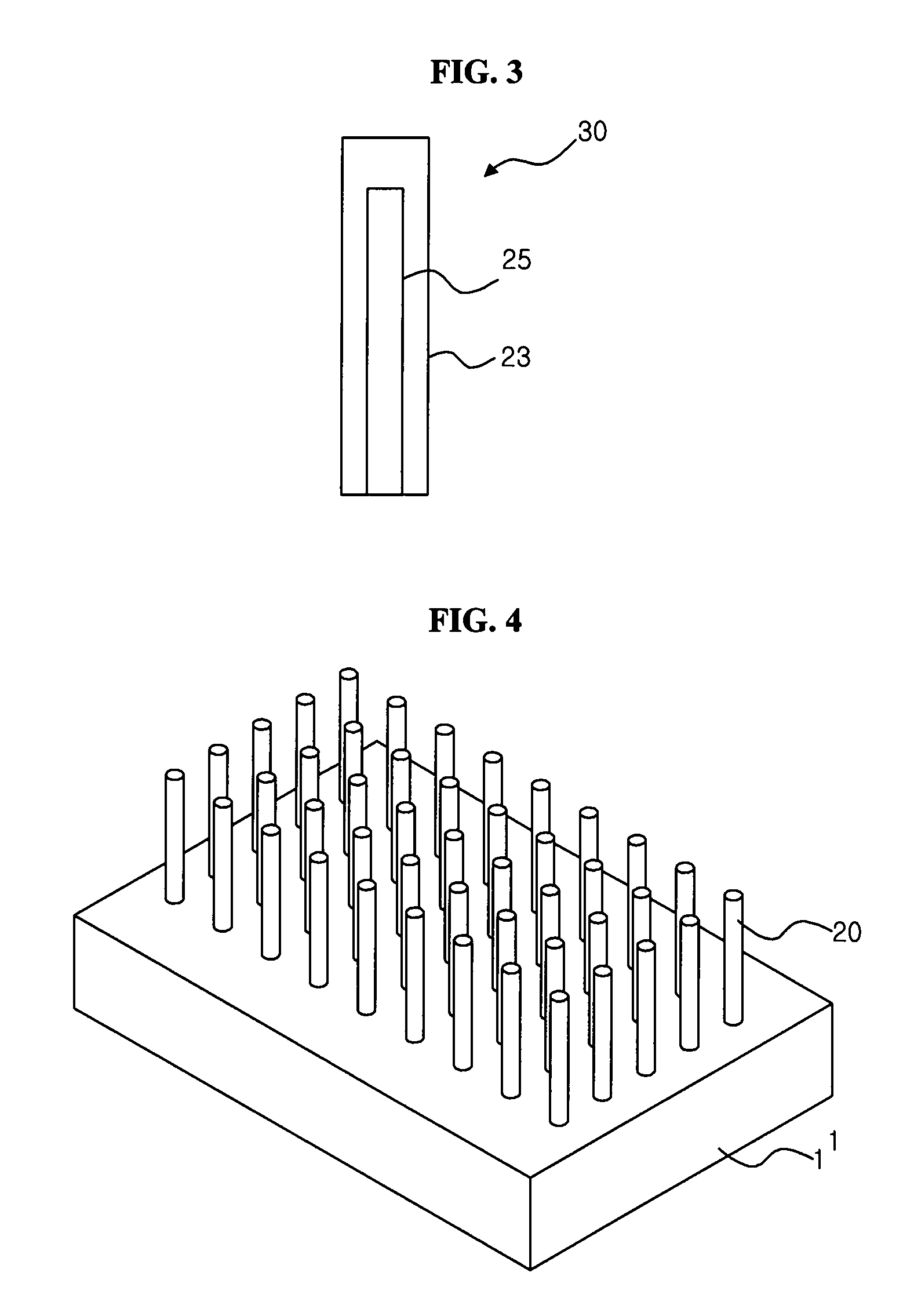

Nanostructure Having a Nitride-Based Quantum Well and Light Emitting Diode Employing the Same

ActiveUS20080157057A1Increase brightnessReduce impactNanostructure manufactureSemiconductor/solid-state device manufacturingQuantum efficiencyNanostructure

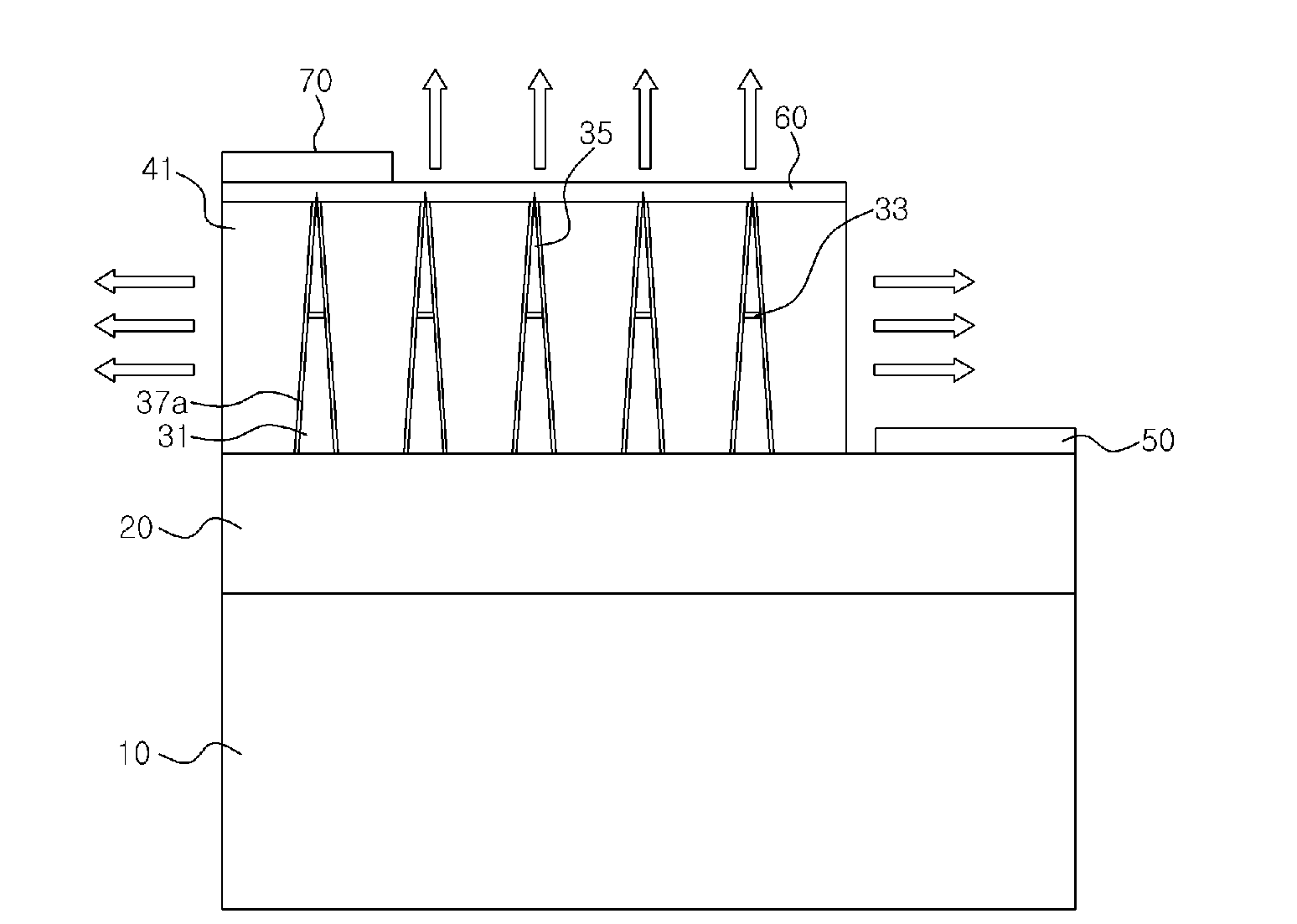

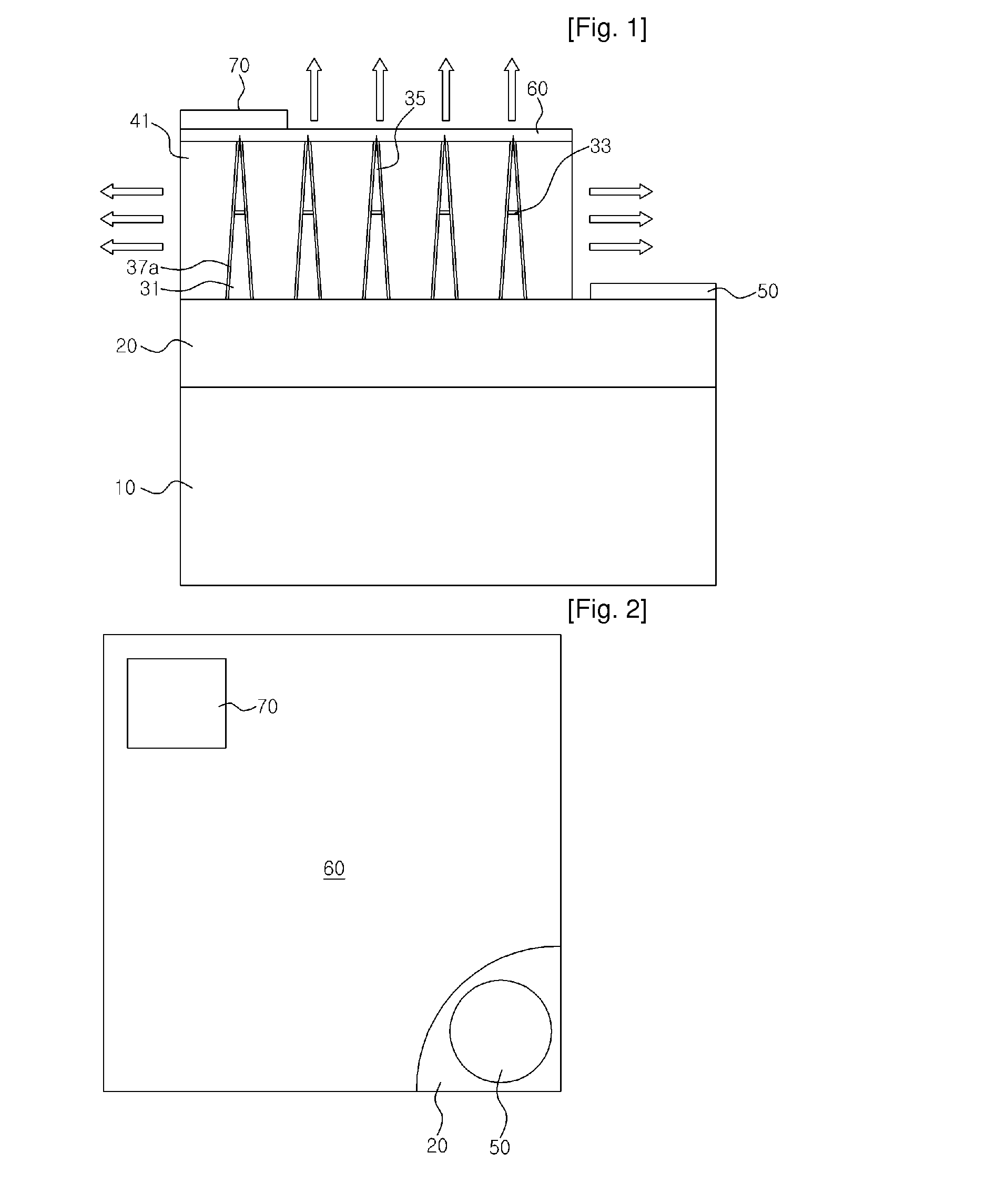

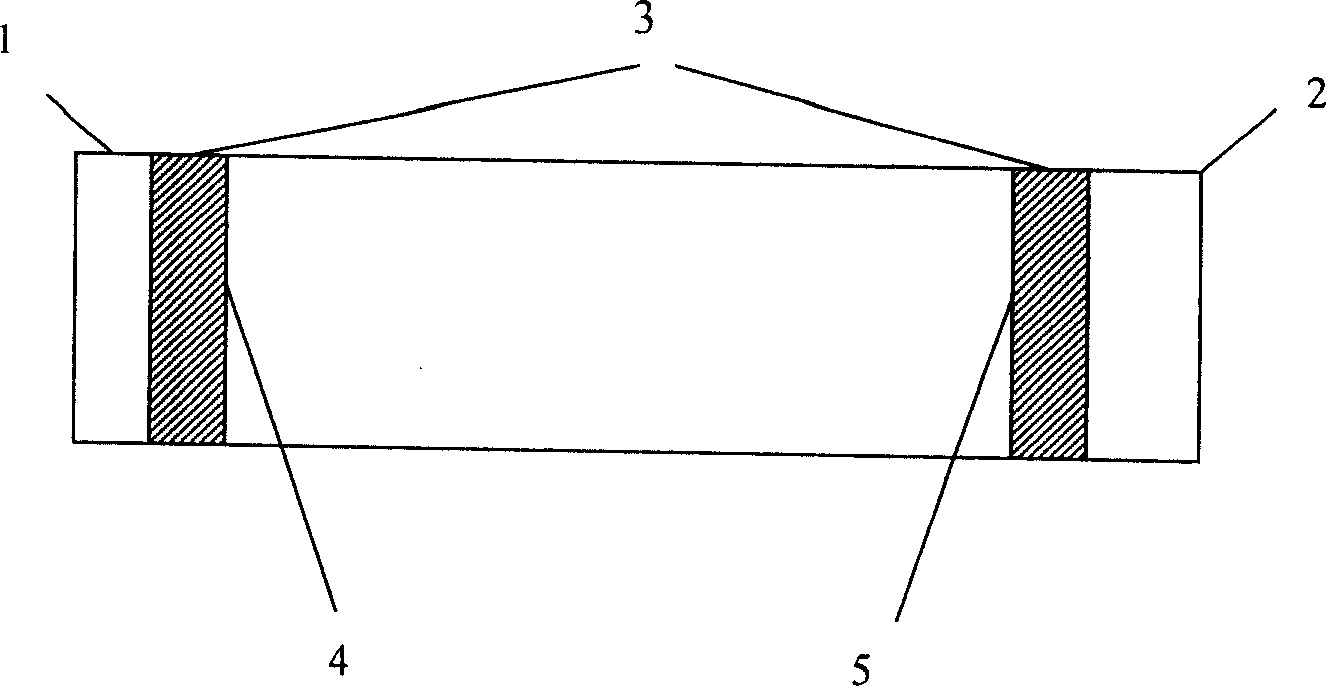

Disclosed are a nanostructure with an indium gallium nitride quantum well and a light emitting diode employing the same. The light emitting diode comprises a substrate, a transparent electrode and an array of nanostructures interposed between the substrate and the transparent electrode. Each of the nanostructures comprises a core nanorod, and a nano shell surrounding the core nanorod. The core nanorod is formed substantially perpendicularly to the substrate and includes a first nanorod of a first conductivity type, an (AlxInyGa1-x-y)N (where, 0≦x≦1, 0≦y≦1 and 0≦x+y≦1) quantum well, and a second nanorod of a second conductivity type, which are joined in a longitudinal direction. The nano shell is formed of a material with a bandgap greater than that of the quantum well, and surrounds at least the quantum well of the core nanorod. Meanwhile, the second nanorods are connected in common to the transparent electrode. Accordingly, with the nano shells, it is possible to provide a light emitting diode capable of improving external quantum efficiency by preventing non-radiative recombination on a surface of the (AlxInyGa1-x-y)N quantum well.

Owner:SEOUL VIOSYS CO LTD

Methods of hyperdoping semiconductor materials and hyperdoped semiconductor materials and devices

InactiveUS7179329B2Easy to operateIncrease computing speedTransistorPolycrystalline material growthSide effectSemiconductor materials

Methods are disclosed for producing highly doped semiconductor materials. Using the invention, one can achieve doping densities that exceed traditional, established carrier saturation limits without deleterious side effects. Additionally, highly doped semiconductor materials are disclosed, as well as improved electronic and optoelectronic devices / components using said materials. The innovative materials and processes enabled by the invention yield significant performance improvements and / or cost reductions for a wide variety of semiconductor-based microelectronic and optoelectronic devices / systems.Materials are grown in an anion-rich environment, which, in the preferred embodiment, are produced by moderate substrate temperatures during growth in an oxygen-poor environment. The materials exhibit fewer non-radiative recombination centers at higher doping concentrations than prior art materials, and the highly doped state of matter can exhibit a minority carrier lifetime dominated by radiative recombination at higher doping levels and higher majority carrier concentrations than achieved in prior art materials. Important applications enabled by these novel materials include high performance electronic or optoelectronic devices, which can be smaller and faster, yet still capture or emit light efficiently, and high performance electronics, such as transistors, which can be smaller and faster, yet cooler.

Owner:YALE UNIV

Multichamber split processes for LED manufacturing

InactiveUS20110081771A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingVapor phaseChemical vapor deposition

Embodiments described herein generally relate to methods for forming Group III-V materials by metal-organic chemical vapor deposition (MOCVD) processes and / or hydride vapor phase epitaxial (HVPE) processes. In one embodiment, deposition of a group III1-N layer on a substrate is performed in a first chamber, deposition of a group III2-N layer on the substrate is performed in a second chamber, and deposition of a group III3-N layer on the substrate is performed in a chamber different from the chamber where the group III2-N layer is deposited. Between the group III2-N layer deposition and the group III3-N layer deposition, one or more surface treatment processes are performed on the substrate to reduce non-radiative recombination at the interface and improve overall electroluminescence of the produced structure.

Owner:APPLIED MATERIALS INC

Field effect semiconductor device

InactiveUS6355951B1Increase resistanceWell mixedTransistorSemiconductor/solid-state device manufacturingLow noiseHigh resistance

In a field effect transistor such as high output FET or low noise HEMT, a layer for facilitating re-combination of carriers (for example a superlattice buffer layer), an undoped compound semiconductor layer having a higher resistance than a channel layer and the channel layer made of a compound semiconductor are layered successively. In the layer for facilitating re-combination of carriers, for example, oxygen of high concentration is introduced, to facilitate the non-radiative recombination which shortens the life of injected carriers. The layer for facilitating re-combination of carriers is also formed by forming the superlattice layer at a lower temperature than the channel layer. Thus, efficiency and voltageproofness on high frequency, high output power operation is improved further, and noises can be decreased further on high frequency, low noise operation.

Owner:MITSUBISHI ELECTRIC CORP

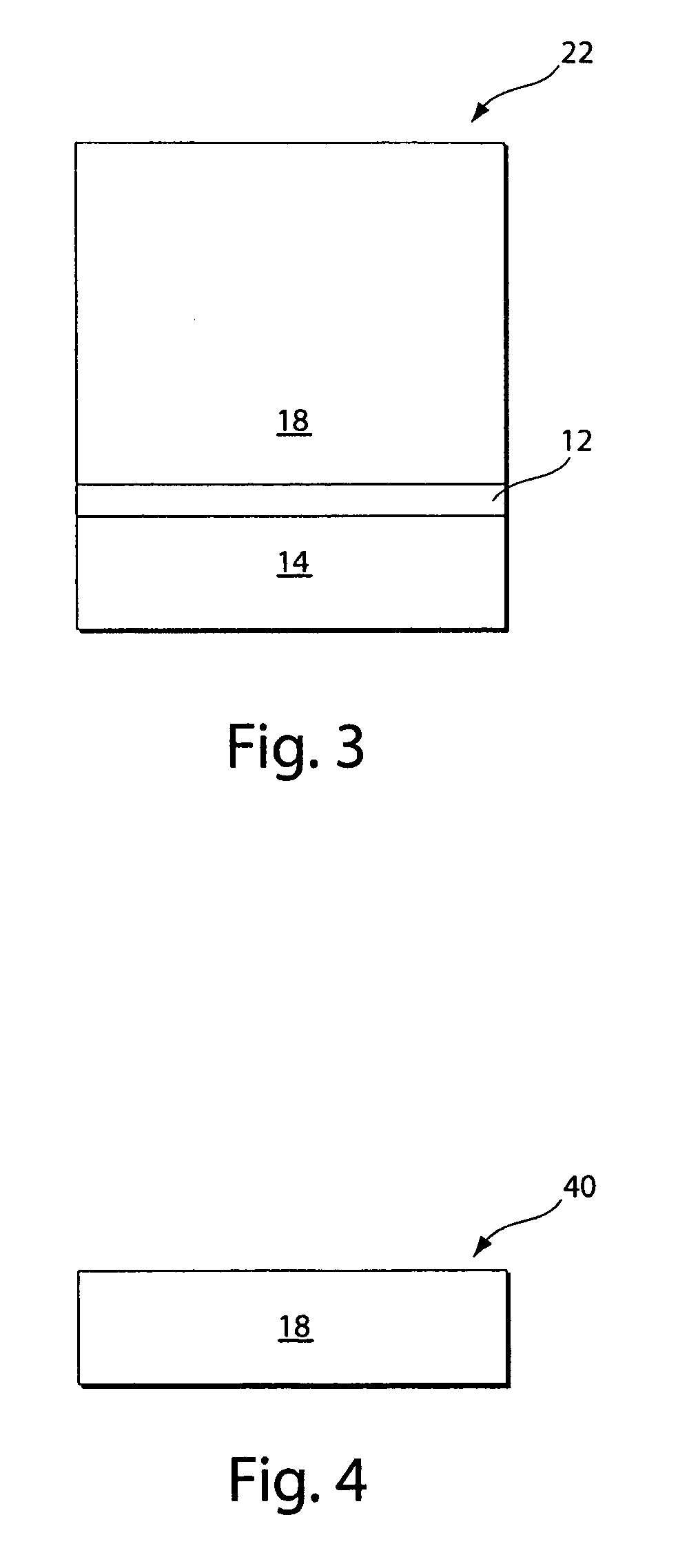

III-nitride materials including low dislocation densities and methods associated with the same

ActiveUS7687827B2Polycrystalline material growthSemiconductor/solid-state device manufacturingElectronic transmissionSemiconductor structure

Semiconductor structures including one, or more, III-nitride material regions (e.g., gallium nitride material region) and methods associated with such structures are provided. The III-nitride material region(s) advantageously have a low dislocation density and, in particular, a low screw dislocation density. In some embodiments, the presence of screw dislocations in the III-nitride material region(s) may be essentially eliminated. The presence of a strain-absorbing layer underlying the III-nitride material region(s) and / or processing conditions can contribute to achieving the low screw dislocation densities. In some embodiments, the III-nitride material region(s) having low dislocation densities include a gallium nitride material region which functions as the active region of the device. The low screw dislocation densities of the active device region (e.g., gallium nitride material region) can lead to improved properties (e.g., electrical and optical) by increasing electron transport, limiting non-radiative recombination, and increasing compositional / growth uniformity, amongst other effects.

Owner:MACOM TECH SOLUTIONS HLDG INC

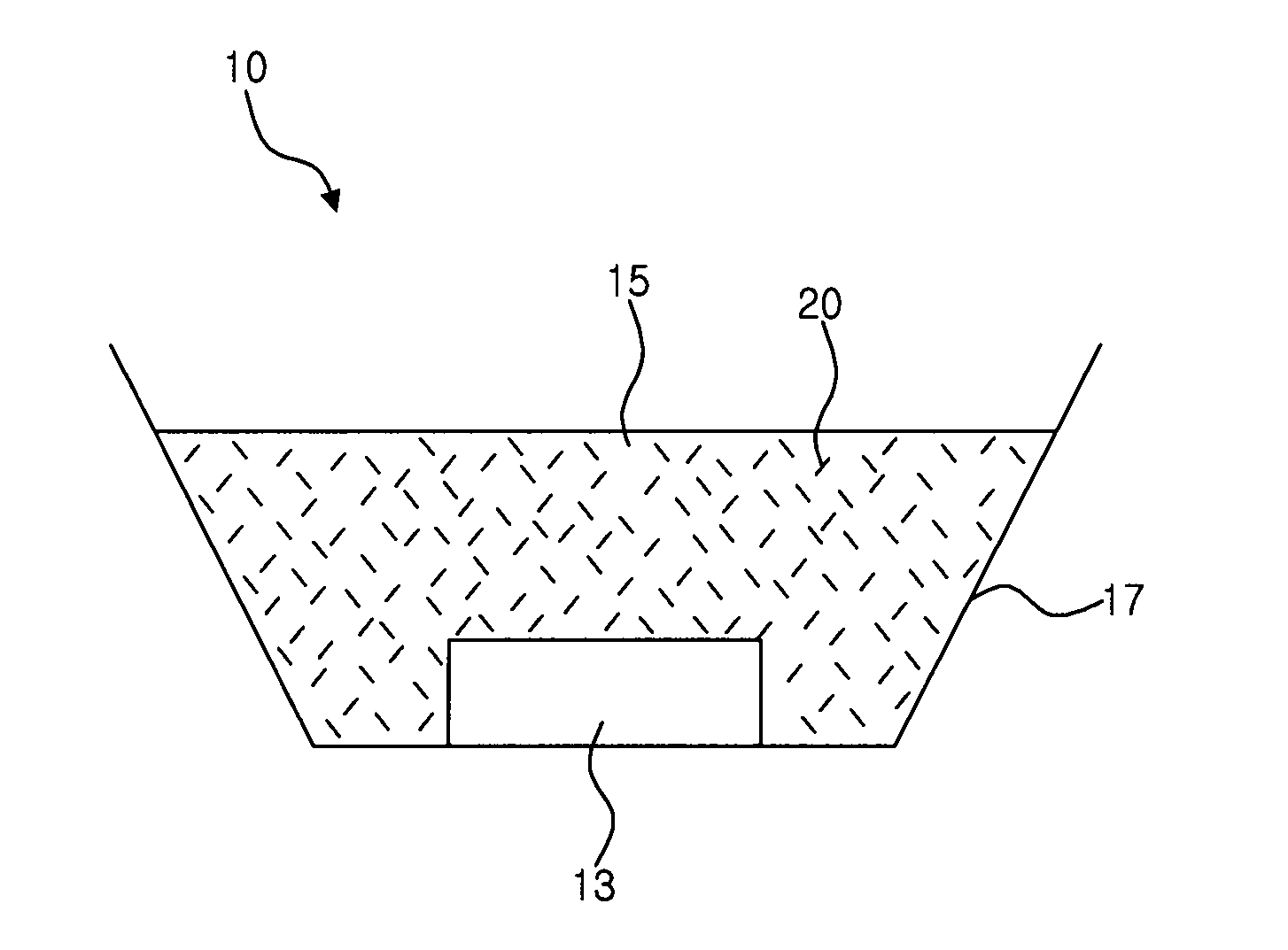

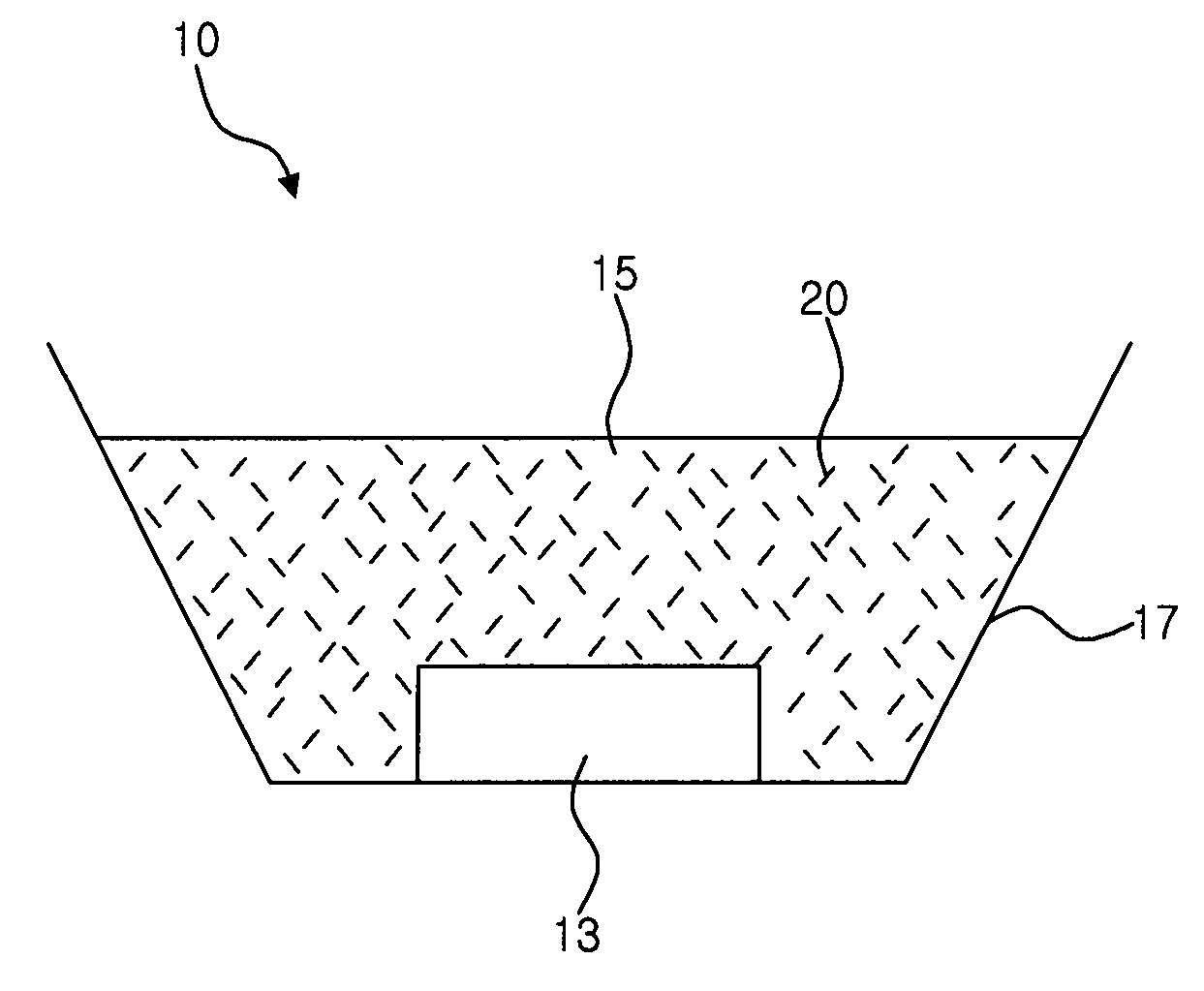

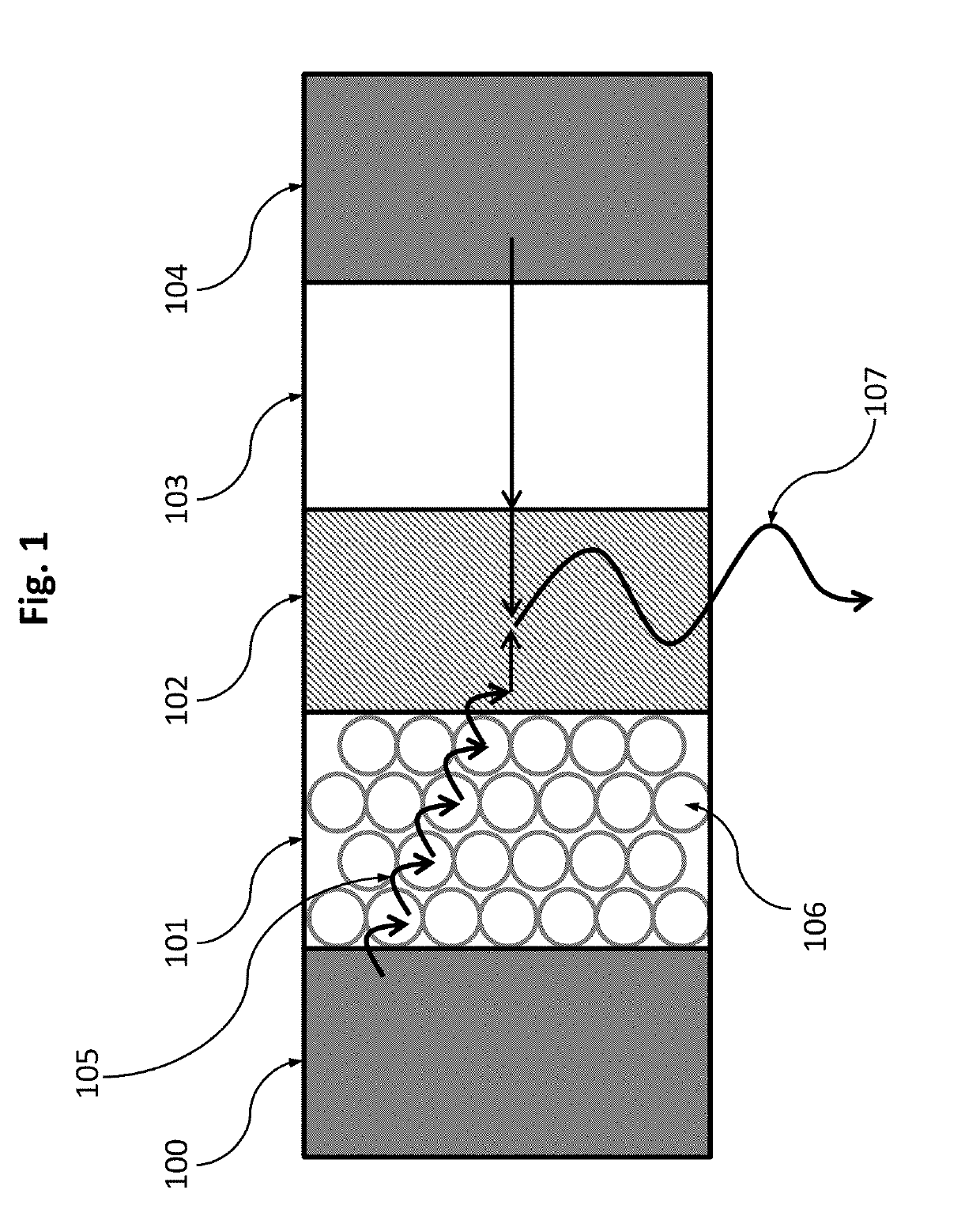

Lighting Emitting Device Employing Nanowire Phosphors

ActiveUS20080185604A1Reduce light lossReduce in quantityNanotechLuminescent compositionsNanowirePhosphor

Disclosed is a light emitting device employing nanowire phosphors. The light emitting device comprises a light emitting diode for emitting light having a first wavelength with a main peak in an ultraviolet, blue or green wavelength range; and nanowire phosphors for converting at least a portion of light having the first wavelength emitted from the light emitting diode into light with a second wavelength longer than the first wavelength. Accordingly, since the nanowire phosphors are employed, it is possible to reduce manufacturing costs of the light emitting device and to reduce light loss due to non-radiative recombination.

Owner:SEOUL VIOSYS CO LTD

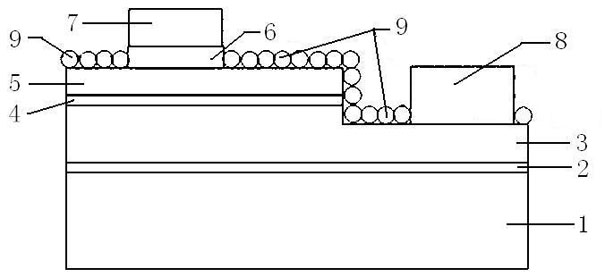

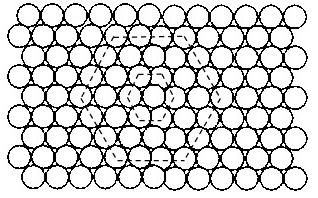

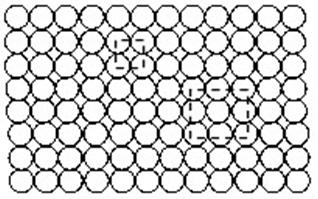

LED with two-dimensional photonic crystals

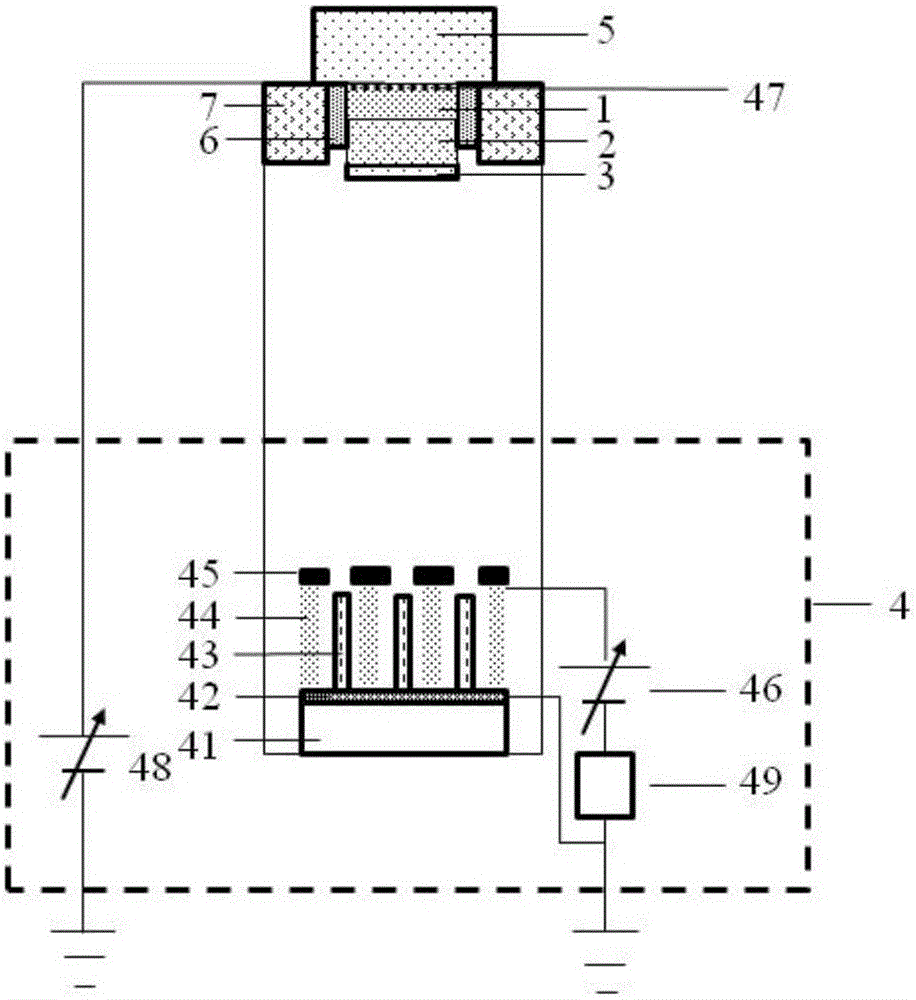

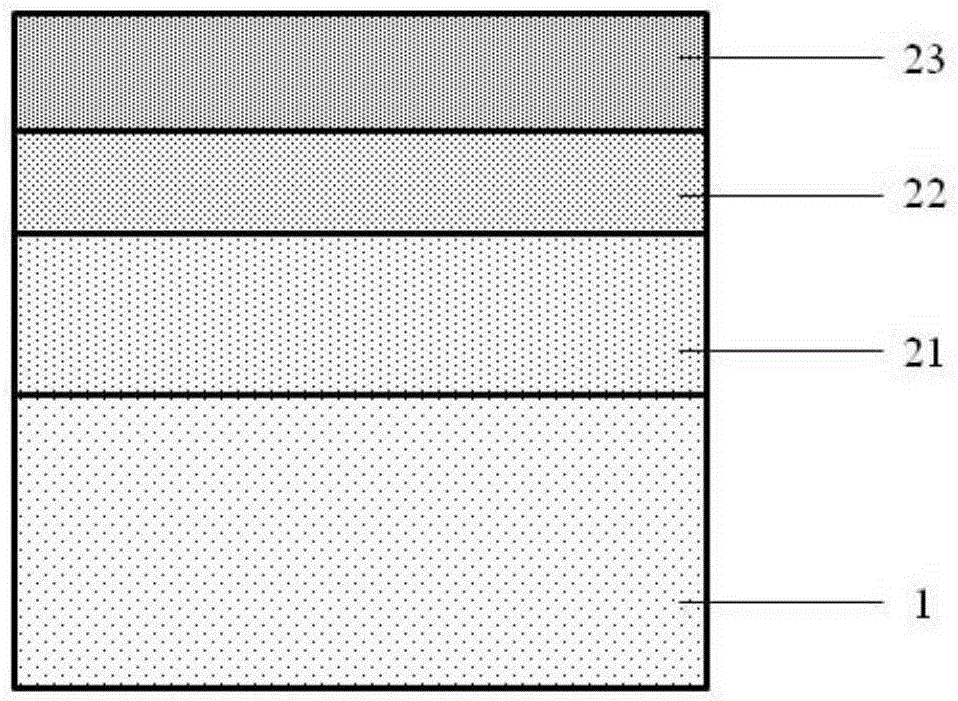

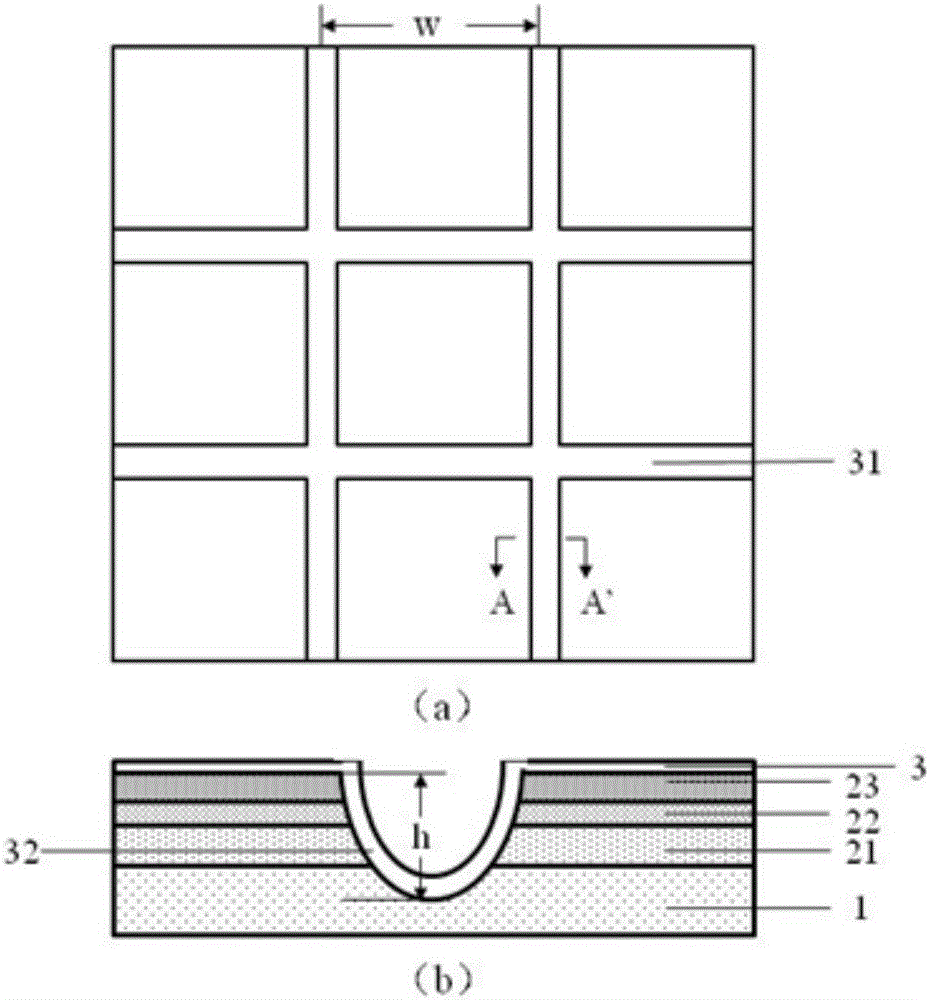

The invention relates to a low cost LED with two-dimensional photonic crystals, and aims to solve the problem that the light-emitting efficiency is low and high production cost, and the problem that non-radiative recombination increases because a semiconductor active layer is damaged by adopting the conventional etching, photo-etching or imprinting technique in the conventional LED. The LED comprises a substrate, a buffer layer, an N-type doped semiconductor layer, an active layer, a P-type doped semiconductor layer, a current diffusing layer, a P-type electrode and an N-type electrode, wherein two-dimensional photonic crystal layers are covered on the interface between the N-type doped semiconductor layer and the air and the interface between the P-type doped semiconductor layer and the air; and the two-dimensional photonic crystal layer adopts a single-layer micro-sphere ordered arrangement structure, and the grain size of the micro-spheres is 50nm to 5 mu m. In the LED, by using the two-dimensional photonic crystal layer, a refraction index difference between the semiconductor and the outside is improved; and by utilizing the weak photonic crystal effect, a light-emitting efficiency is improved by 10 to 20 percent compared with that of the conventional LED. The LED of the invention is suitable for large-area and industrialized production.

Owner:HARBIN INST OF TECH

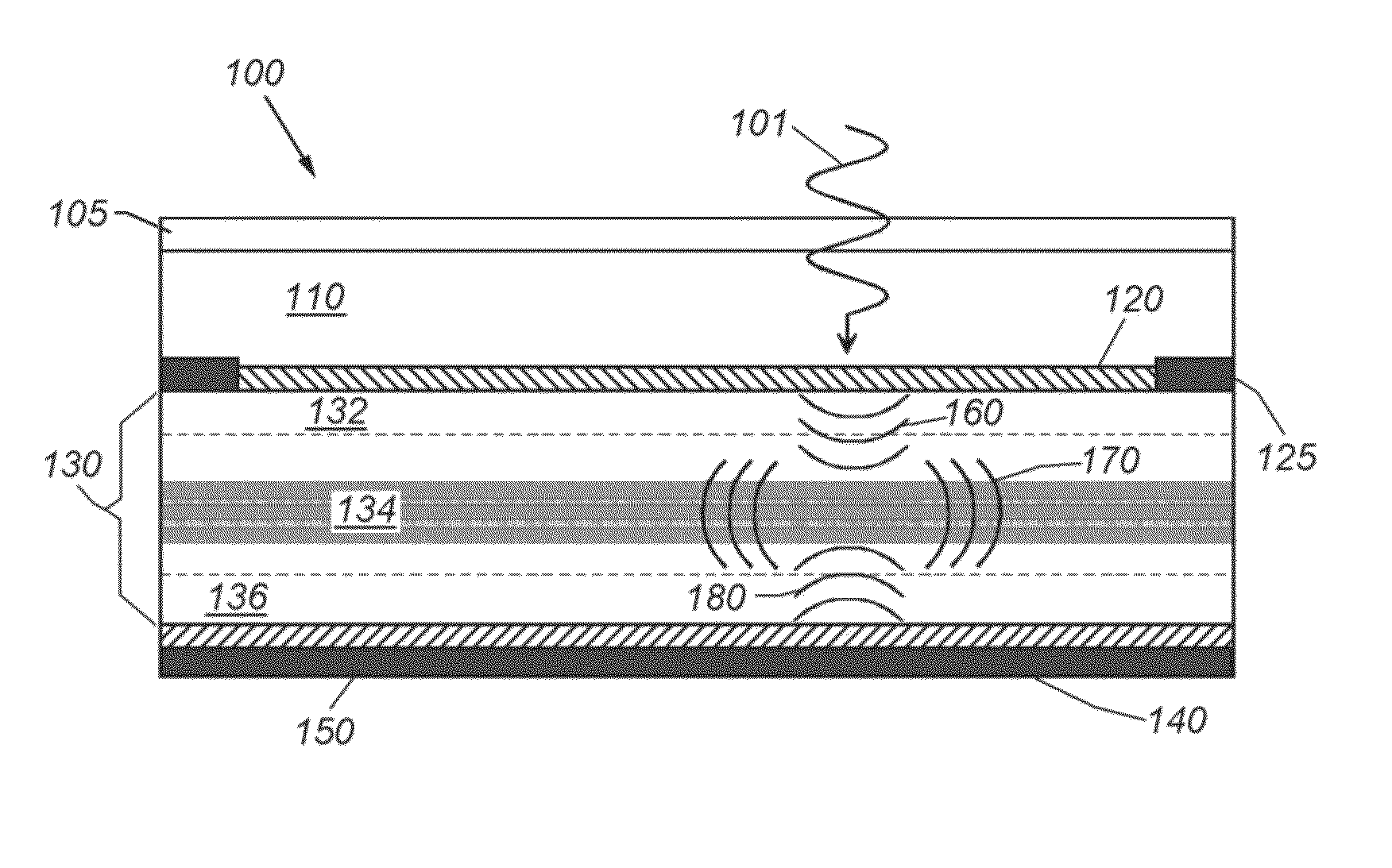

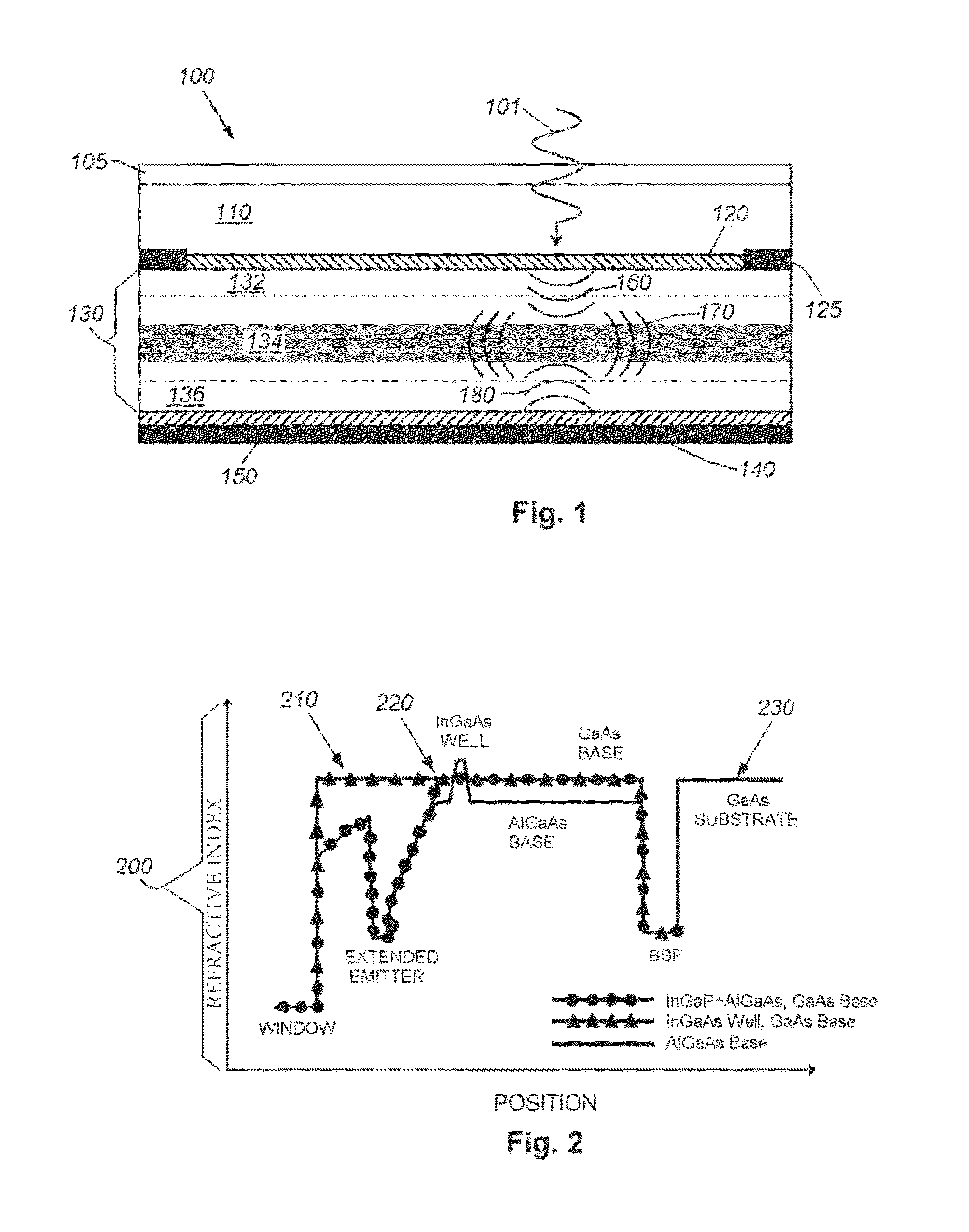

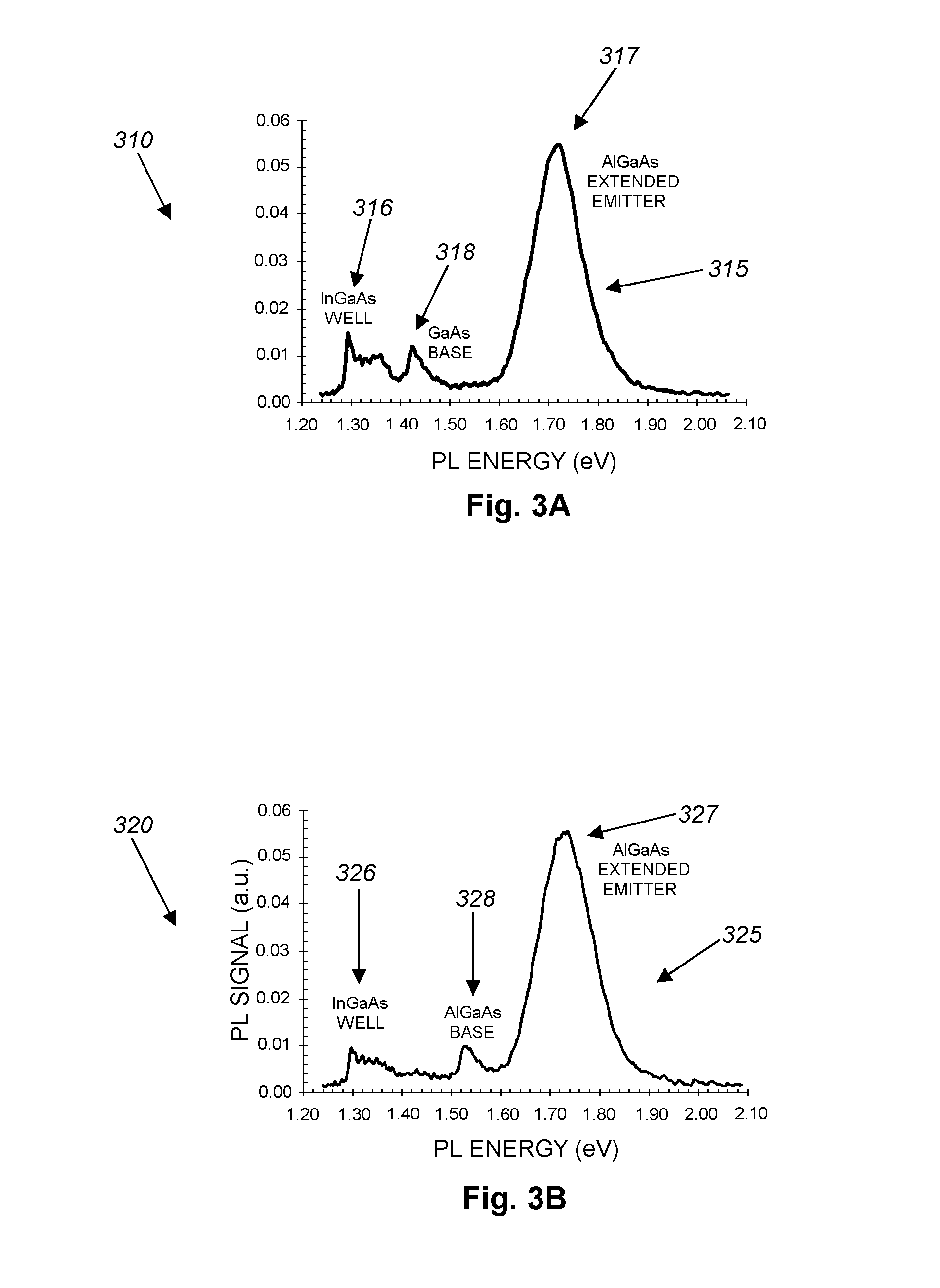

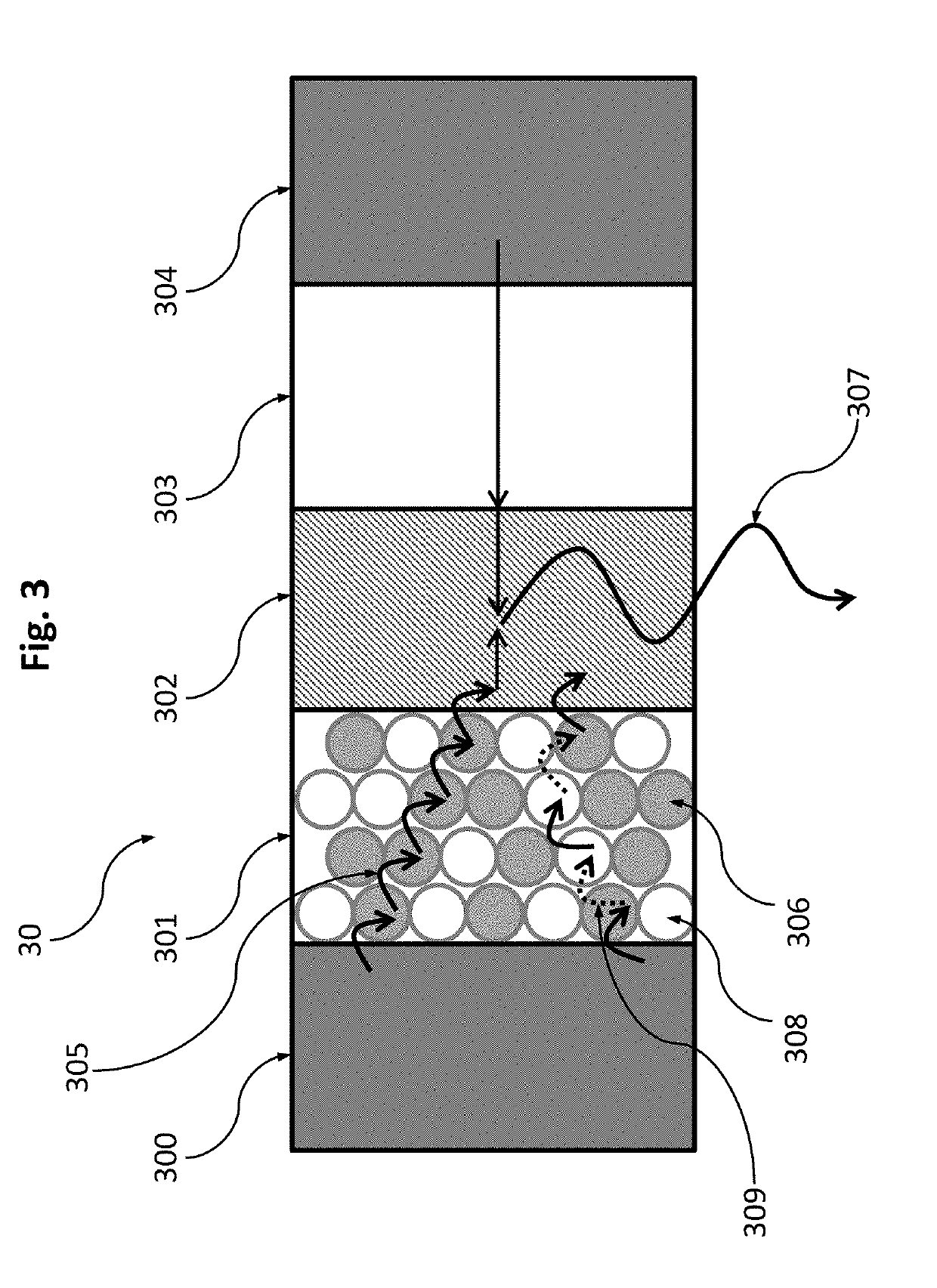

High efficiency quantum well waveguide solar cells and methods for constructing the same

ActiveUS8921687B1Increase the open circuit voltageMinimise currentFinal product manufacturePhotovoltaic energy generationHeterojunctionIn plane

Photon absorption, and thus current generation, is hindered in conventional thin-film solar cell designs, including quantum well structures, by the limited path length of incident light passing vertically through the device. Optical scattering into lateral waveguide structures provides a physical mechanism to increase photocurrent generation through in-plane light trapping. However, the insertion of wells of high refractive index material with lower energy gap into the device structure often results in lower voltage operation, and hence lower photovoltaic power conversion efficiency. The voltage output of an InGaAs quantum well waveguide photovoltaic device can be increased by employing a III-V material structure with an extended wide band gap emitter heterojunction. Analysis of the light IV characteristics reveals that non-radiative recombination components of the underlying dark diode current have been reduced, exposing the limiting radiative recombination component and providing a pathway for realizing solar-electric conversion efficiency of 30% or more in single junction cells.

Owner:MAGNOLIA SOLAR

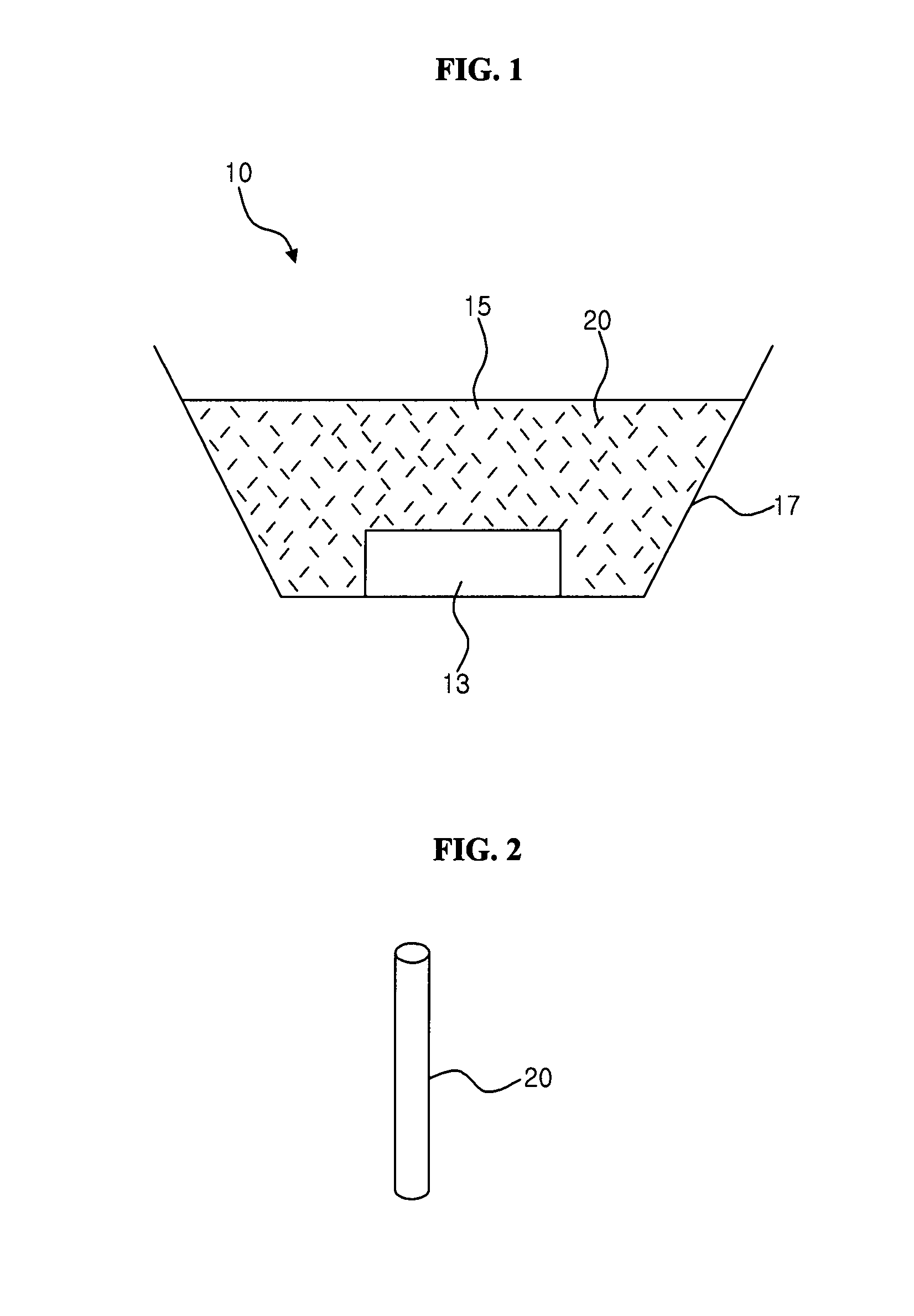

Nanostructure having a nitride-based quantum well and light emitting diode employing the same

ActiveUS8330173B2Increase brightnessReduce impactNanostructure manufactureSemiconductor/solid-state device manufacturingQuantum efficiencyNanostructure

Disclosed are a nanostructure with an indium gallium nitride quantum well and a light emitting diode employing the same. The light emitting diode comprises a substrate, a transparent electrode and an array of nanostructures interposed between the substrate and the transparent electrode. Each of the nanostructures comprises a core nanorod, and a nano shell surrounding the core nanorod. The core nanorod is formed substantially perpendicularly to the substrate and includes a first nanorod of a first conductivity type, an (AlxInyGa1-x-y)N (where, 0≦x<1, 0≦y≦1 and 0≦x+y≦1) quantum well, and a second nanorod of a second conductivity type, which are joined in a longitudinal direction. The nano shell is formed of a material with a bandgap greater than that of the quantum well, and surrounds at least the quantum well of the core nanorod. Meanwhile, the second nanorods are connected in common to the transparent electrode. Accordingly, with the nano shells, it is possible to provide a light emitting diode capable of improving external quantum efficiency by preventing non-radiative recombination on a surface of the (AlxInyGa1-x-y)N quantum well.

Owner:SEOUL VIOSYS CO LTD

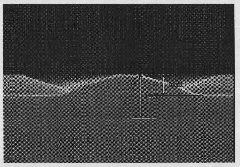

Method for preparing patterned sapphire substrate for extension of gallium nitride-based LED

Owner:WUHAN XIRUI TECH

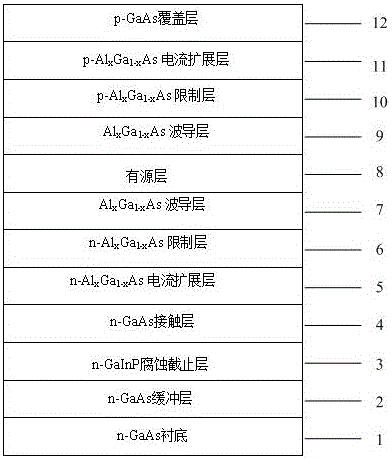

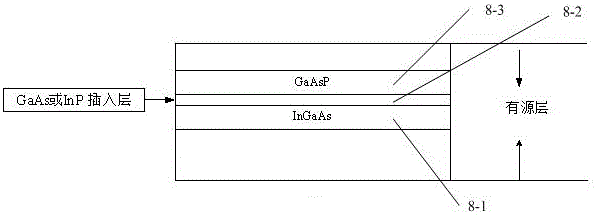

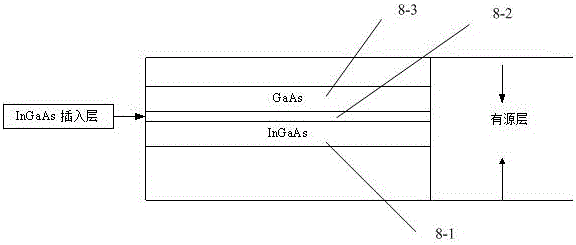

Epitaxial wafer for flip infrared light-emitting diode

InactiveCN106299058AImprove quantum efficiencyLattice Mismatch ReliefSemiconductor devicesQuantum efficiencyCharge carrier

The invention discloses an epitaxial wafer for a flip infrared light-emitting diode, and belongs to the technical field of epitaxy of light emitting diodes. Layers are epitaxially formed on the same side of a substrate in sequence; an active layer comprises InGaAs quantum well layers and GaAsP barrier layers which alternate periodically; the period number is 2 to 6; the active layer adopts an InGaAs / GaAsP strain compensation quantum well structure; the strain compensation quantum well can restrain carriers to flow in place transversely to form non-radiative recombination by mistake, so that the quantum efficiency is improved.

Owner:YANGZHOU CHANGELIGHT

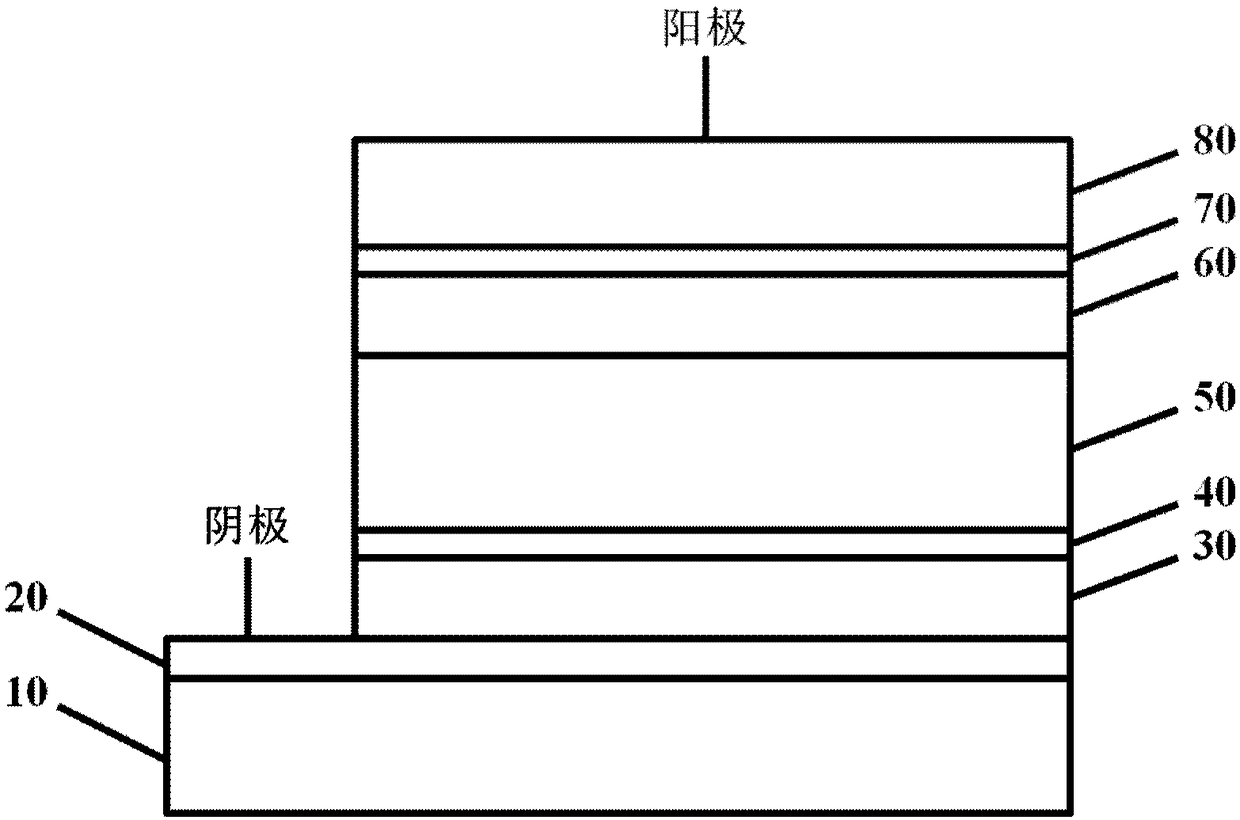

Perovskite composite LED with multiple quantum wells and preparation method thereof

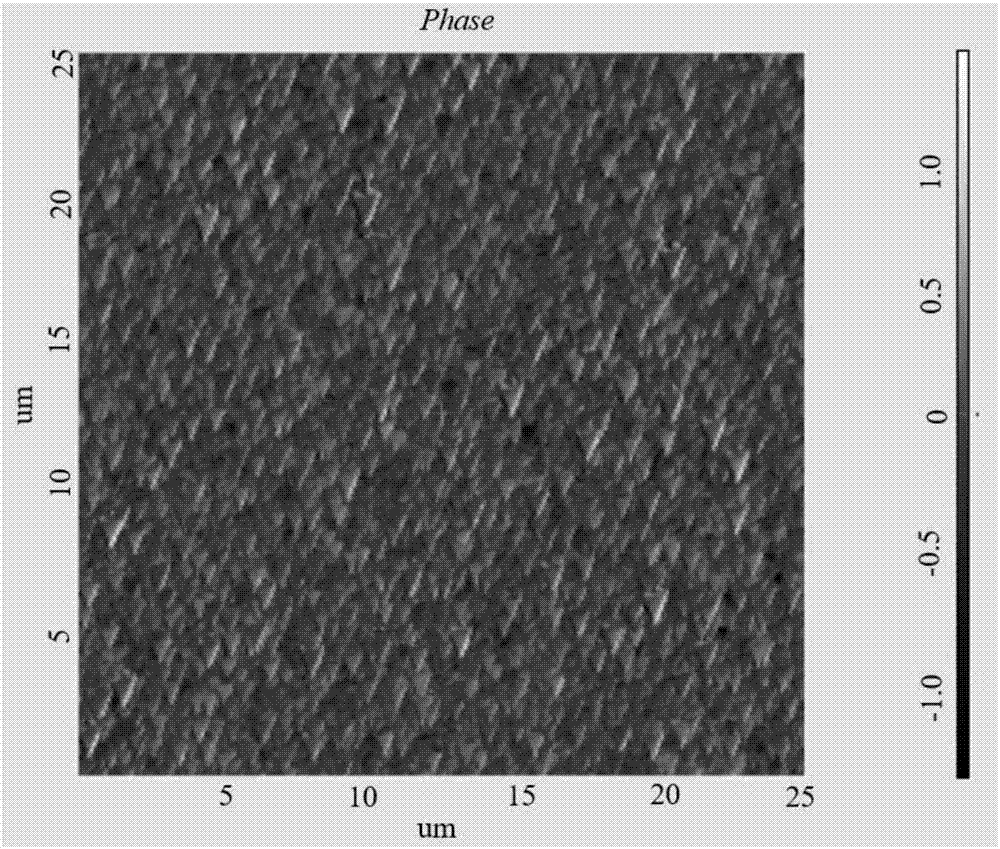

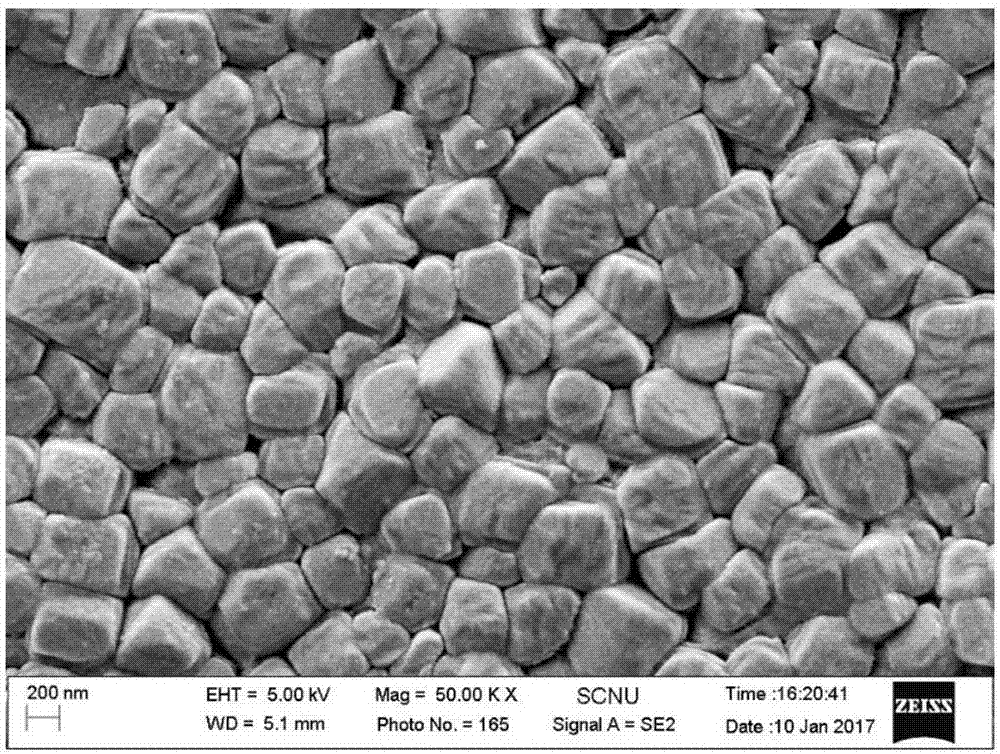

ActiveCN107369774AImprove matchLess structural interface defectsSolid-state devicesSemiconductor/solid-state device manufacturingLuminescenceElectron

The invention provides a perovskite composite LED with multiple quantum wells and a preparation method thereof. The perovskite composite LED with multiple quantum wells comprises a substrate, an electronic injection layer, a luminous layer, a hole injection layer and an electrode which are arranged in sequence; and the luminous layer comprises a CH3NDH3PbBr3 film and CH3NH3PbI3 quantum points embedded in the CH3NDH3PbBr3 film. The perovskite quantum points CH3NH3PbI3 with relatively narrow band gaps are embedded in the perovskite continuous phase CH3NDH3PbBr3 film with a relatively big band gap; and due to high electronics, hole mobility and carrier diffusion length of the perovskite, the quantum effect of the quantum points and multiple quantum wells formed by the perovskite and the quantum points, carriers are guided to the quantum wells with low potential barriers for recombination luminescence. In addition, crystal lattices of perovskite with different components are matched well; the perovskite composite LED with multiple quantum wells, compared with other quantum well structures, has few interface defects; and the non-radiative recombination centers are reduced efficiently.

Owner:SOUTH CHINA NORMAL UNIVERSITY

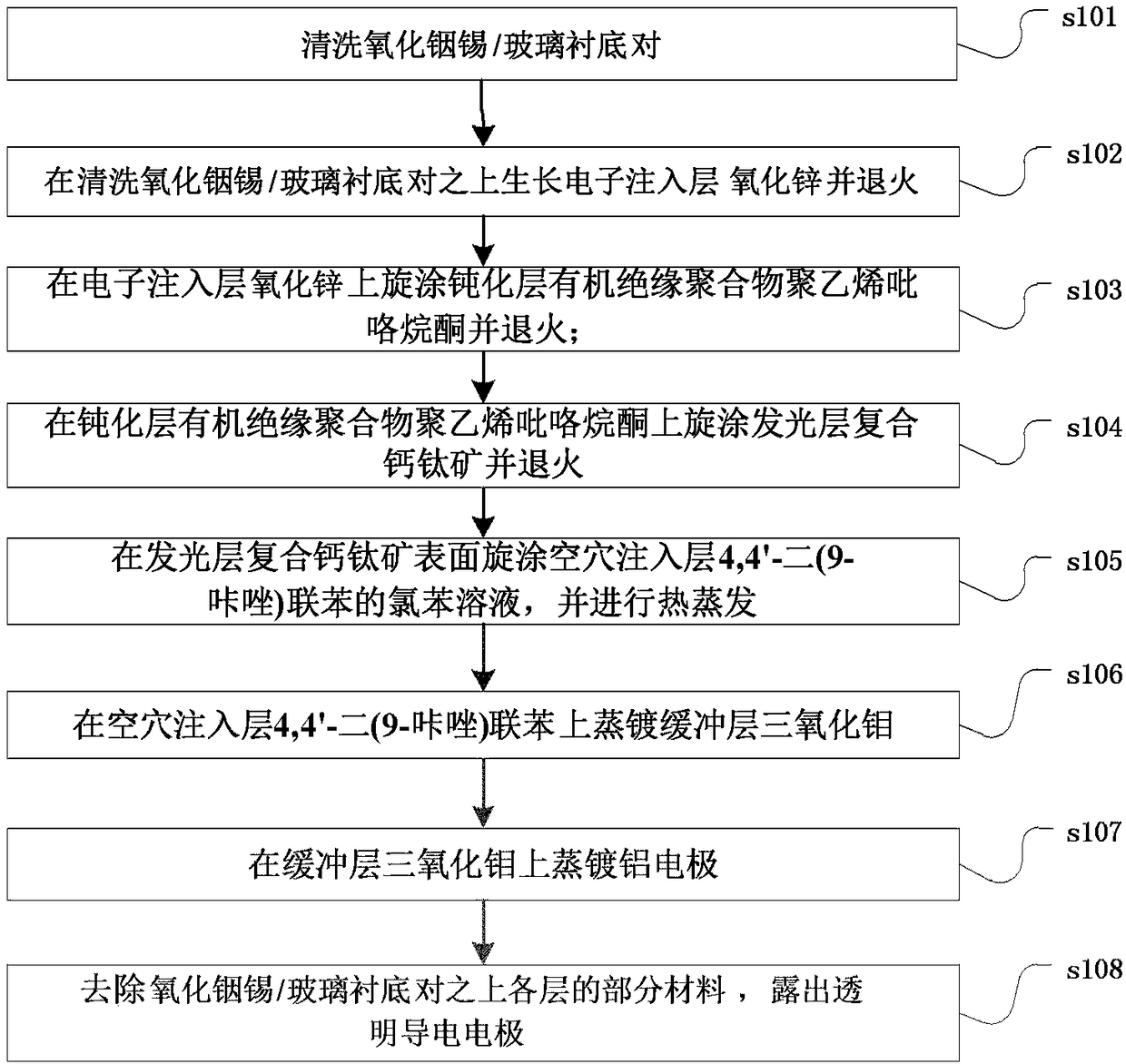

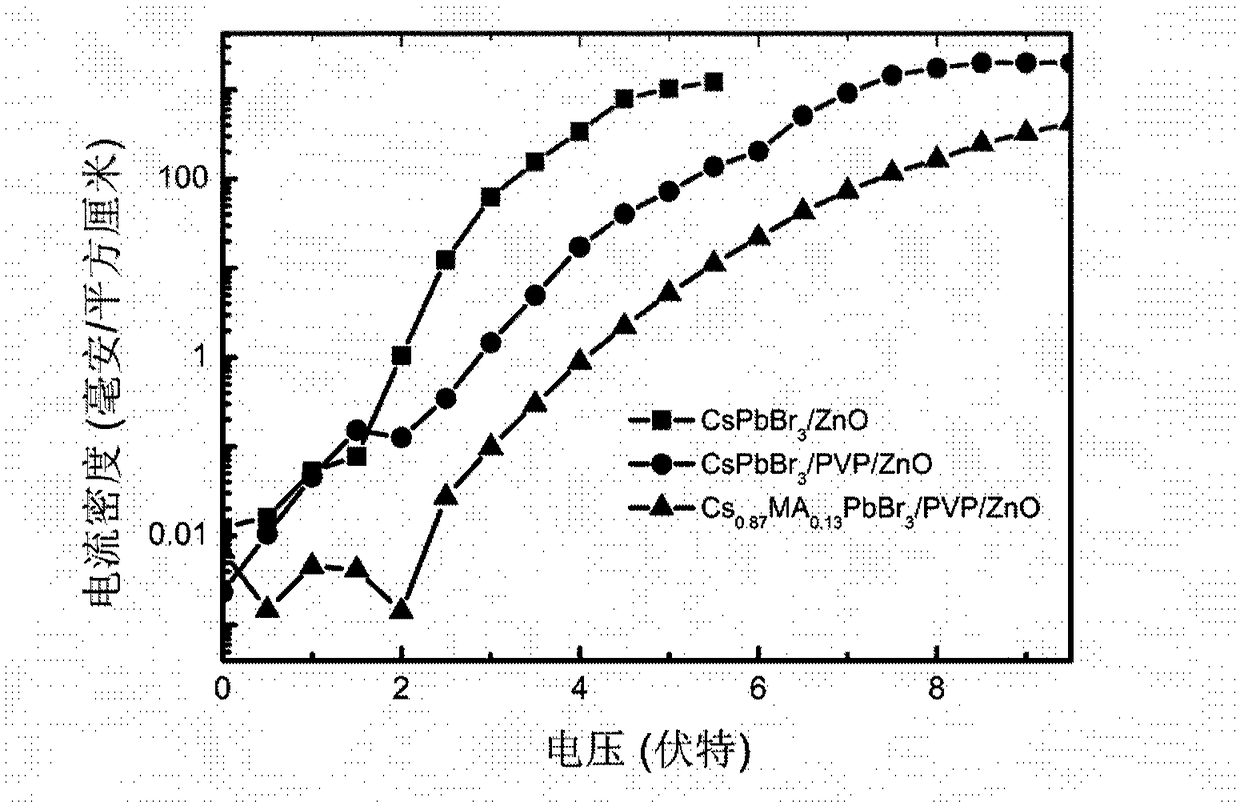

Inorganic perovskite light emitting diode and preparation method thereof

InactiveCN108511633AReduce leakage currentImprove external quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyZinc

The invention discloses an inorganic perovskite light emitting diode and a preparation method thereof. According to the method, a passivation layer (PVP) not only can improve the surface morphology ofthe perovskite and reduce the leakage current of the light emitting diode, but also can passivate surface defects of zinc oxide (ZnO), reduce the non-radiative recombination at the interface betweenthe perovskite and the zinc oxide and thus improve the radiative recombination efficiency, and can also improve the injection balance between electrons and holes at the same time. In addition, a composite perovskite light emitting material (Cs0.87MA0.13PbBr3) which is almost hole-free and very compact can be obtained by doping a small amount of MABr into CsPbBr3, thereby being also capable of effectively suppressing the generation of a non-radiative recombination center of elementary lead in CsPbBr3 while reducing the leakage current. The external quantum efficiency of the perovskite light emitting diode can be effectively improved according to the invention.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Lighting emitting device employing nanowire phosphors

Disclosed is a light emitting device employing nanowire phosphors. The light emitting device comprises a light emitting diode for emitting light having a first wavelength with a main peak in an ultraviolet, blue or green wavelength range; and nanowire phosphors for converting at least a portion of light having the first wavelength emitted from the light emitting diode into light with a second wavelength longer than the first wavelength. Accordingly, since the nanowire phosphors are employed, it is possible to reduce manufacturing costs of the light emitting device and to reduce light loss due to non-radiative recombination.

Owner:SEOUL VIOSYS CO LTD

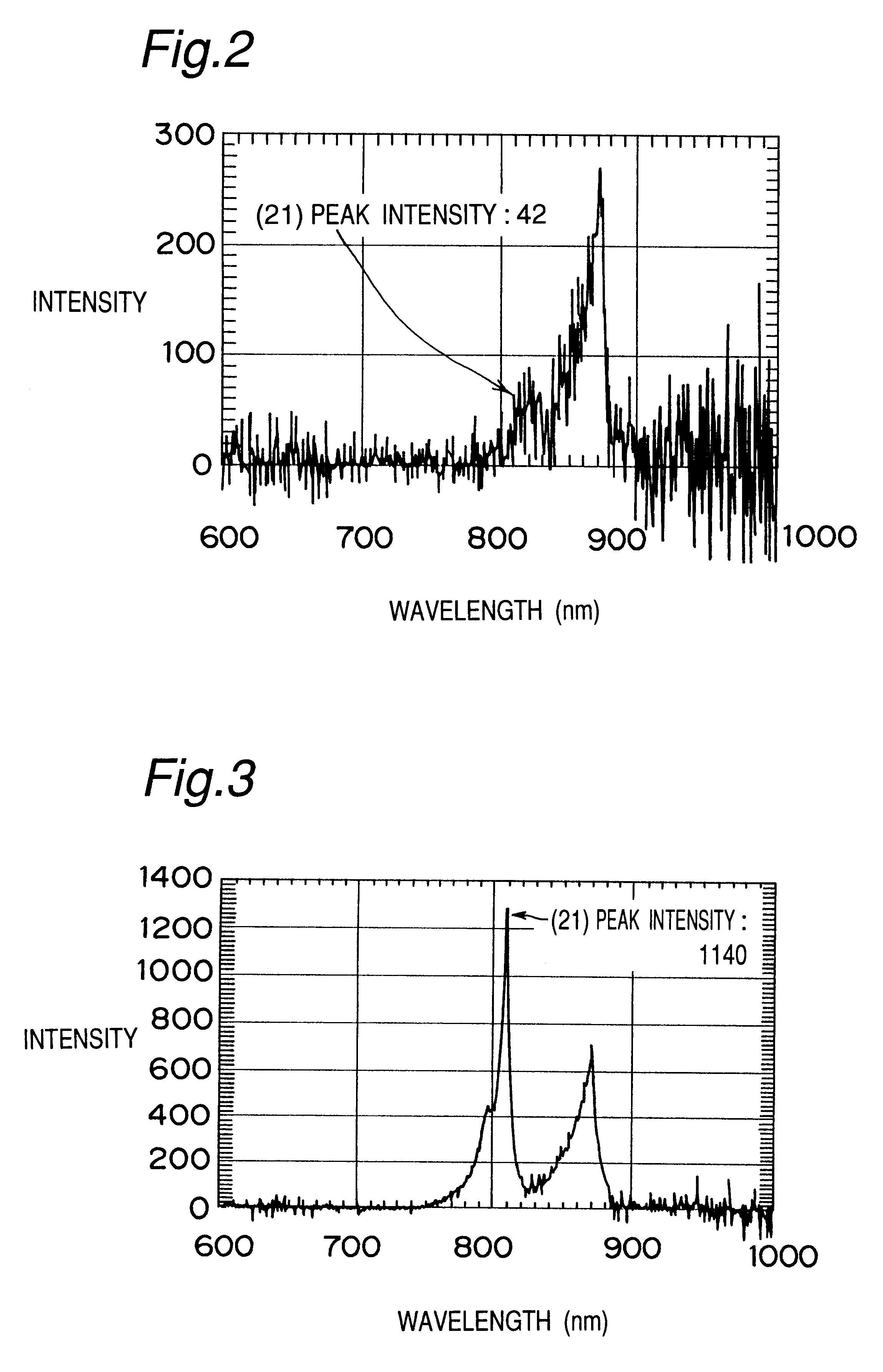

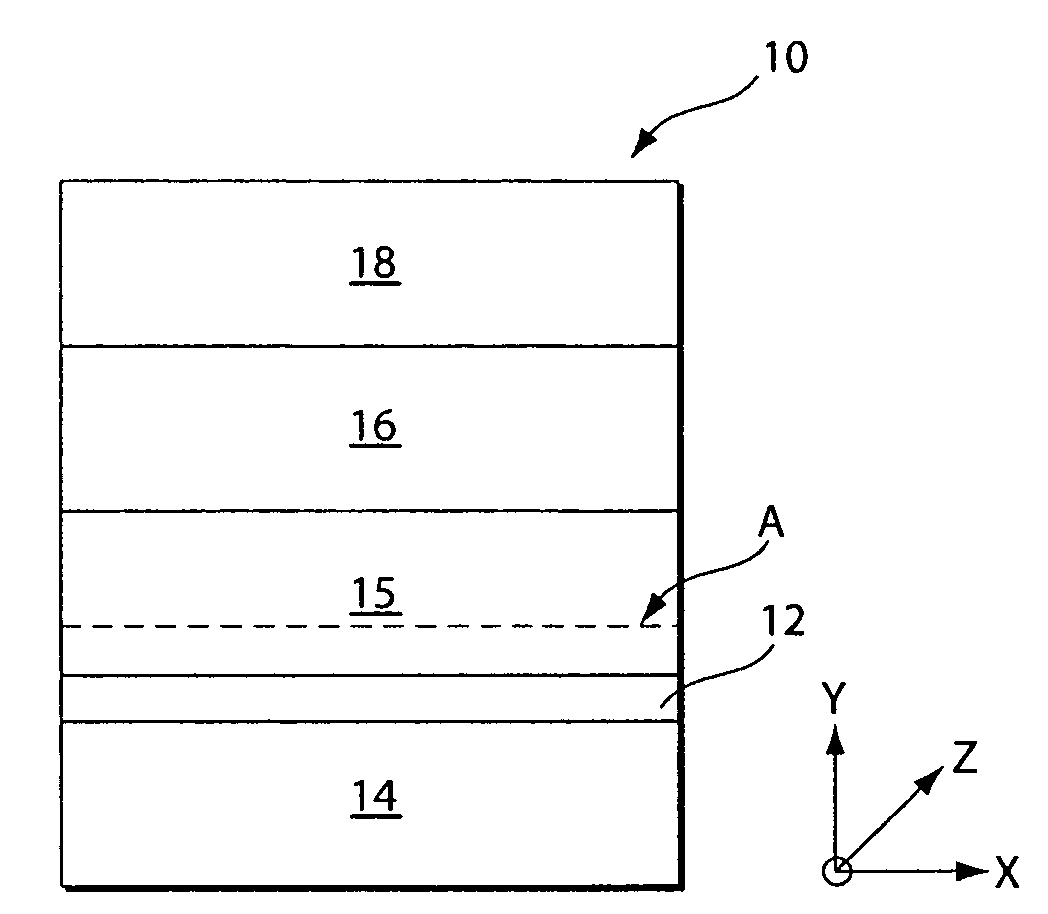

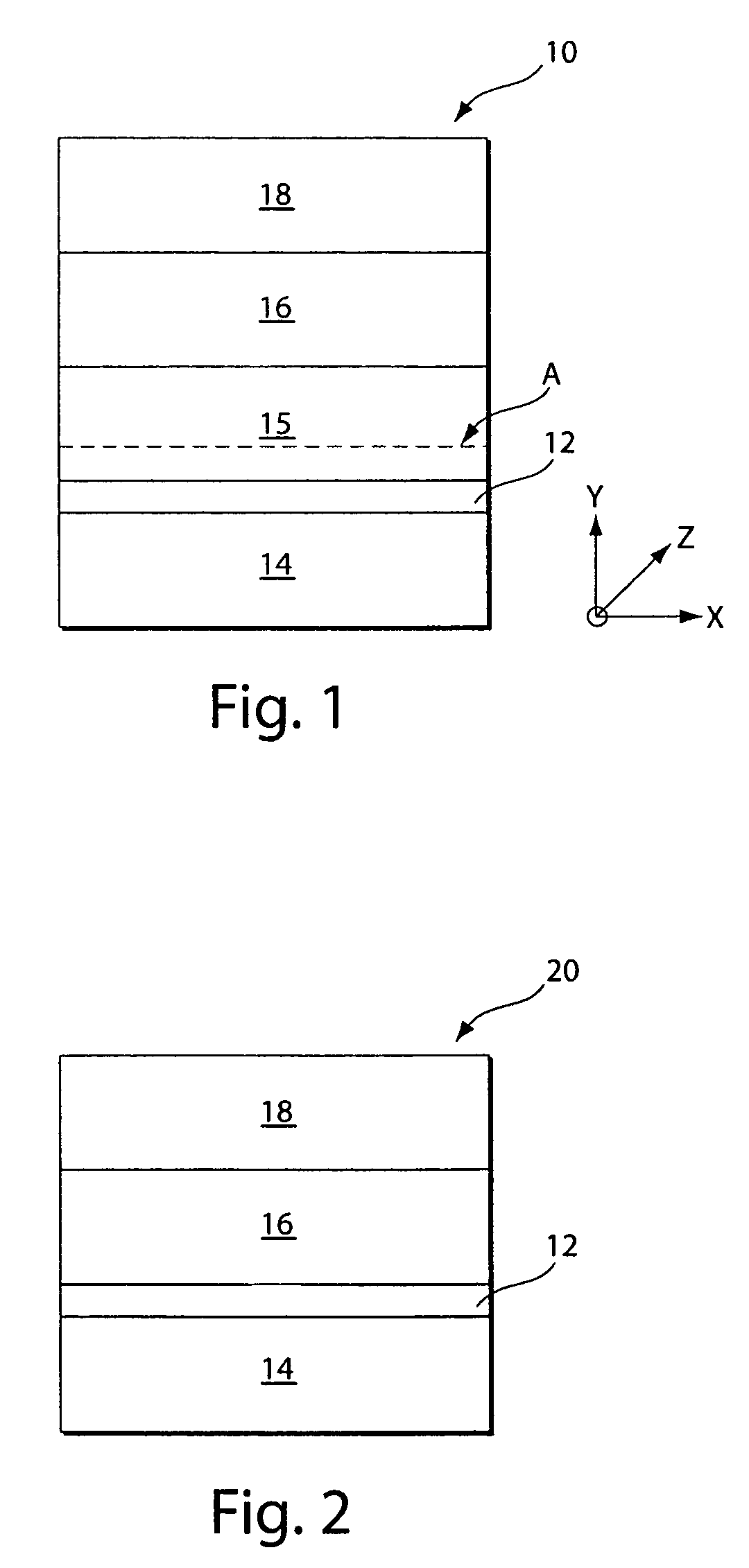

Semiconductor Saturable Absorber Reflector and Method to Fabricate Thereof

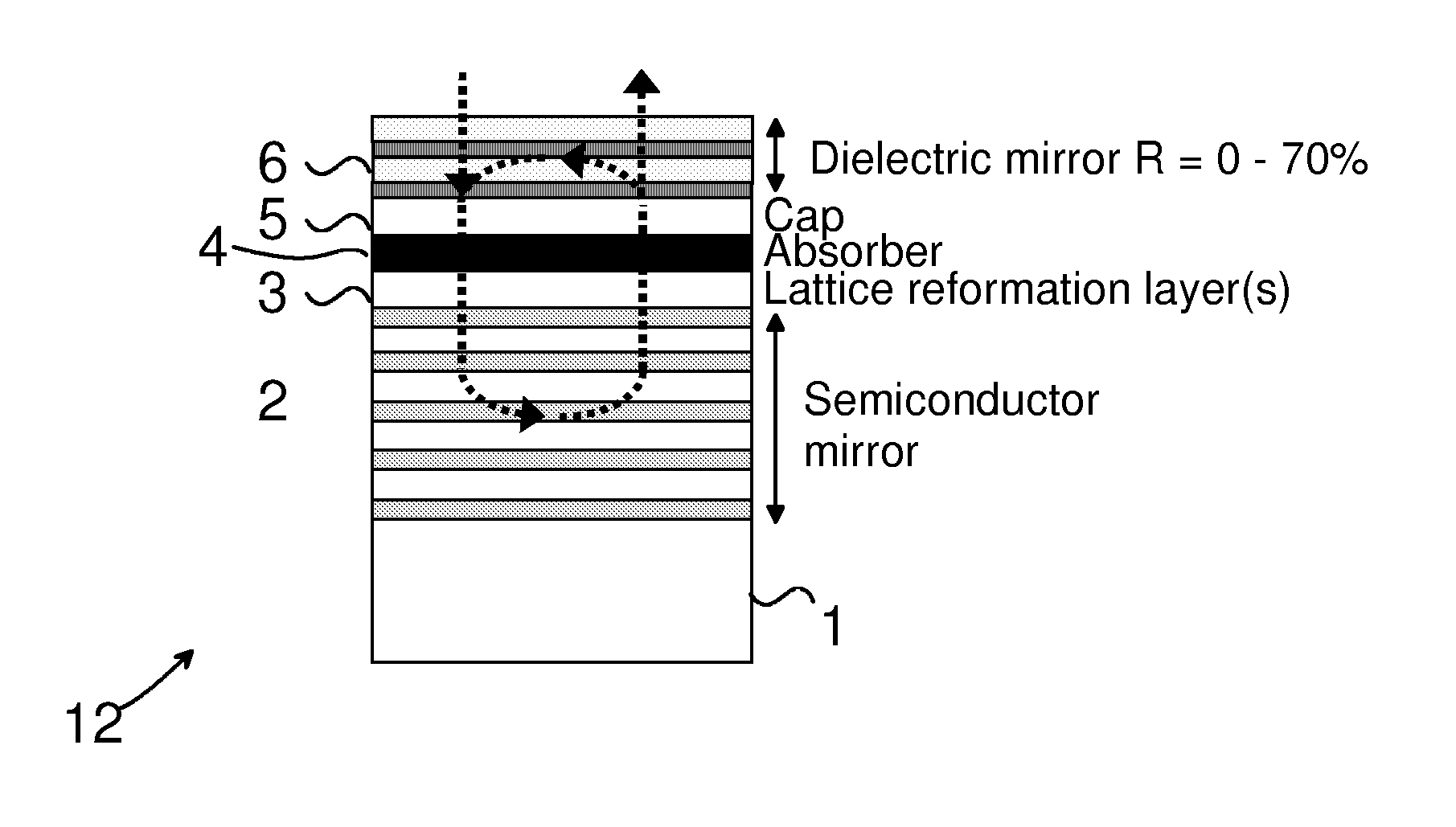

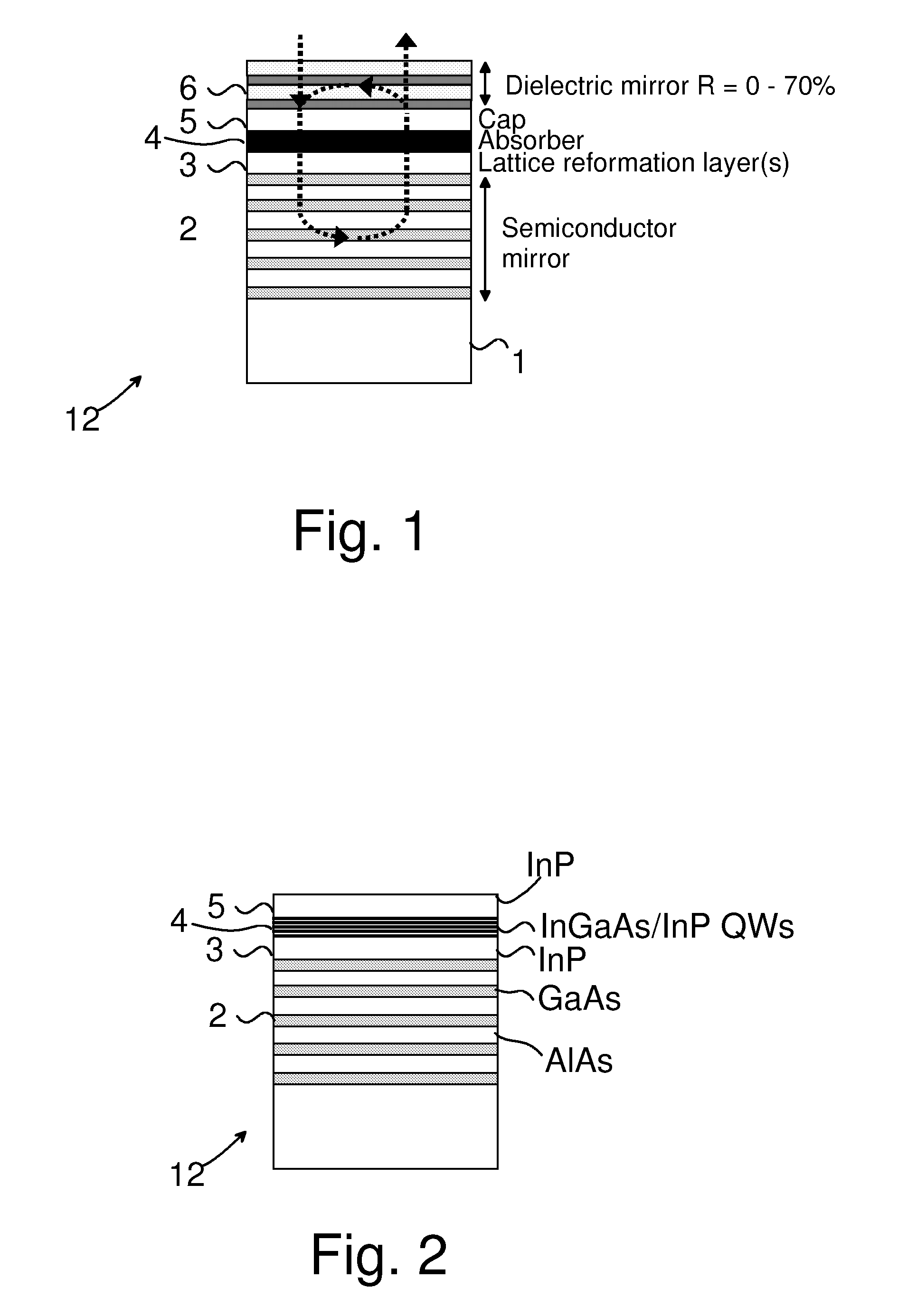

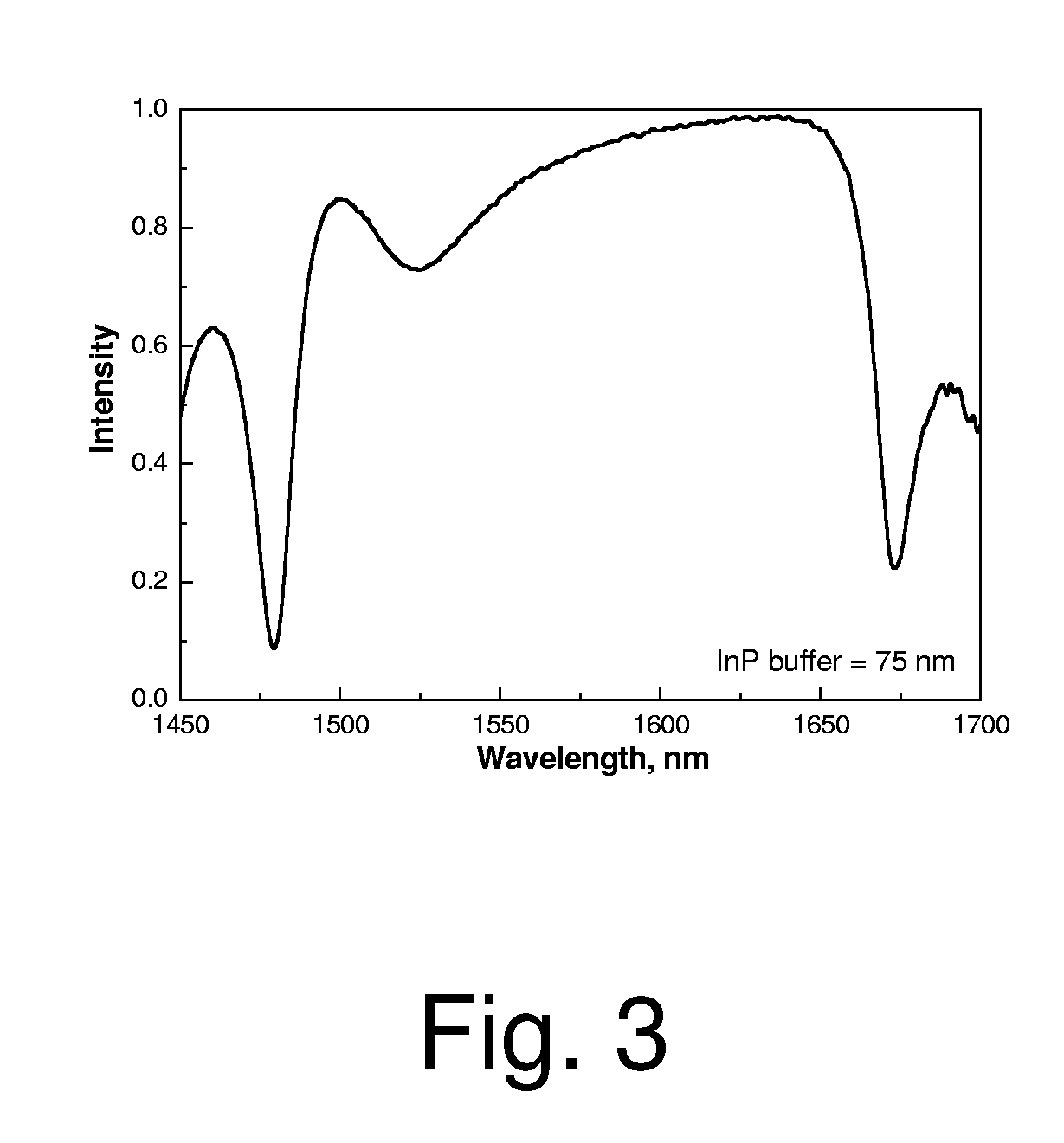

ActiveUS20090296767A1Accurate modificationLimit recovery timeLaser detailsNanoinformaticsSemiconductor materialsLattice mismatch

A design of a semiconductor saturable absorber that offers a convenient and reliable way to control / decrease the recovery time of the absorption. The absorption recovery time is controlled during the epitaxial growth by using lattice-mismatched layer(s) to induce dislocations, and implicitly non-radiative recombination centers within the nonlinear absorbing region. These lattice reformation layer(s) are interposed between the distributed Bragg reflector and the nonlinear absorption region, containing quantum-wells, quantum-dots or bulk semiconductor material. The thickness and composition of the lattice reformation layer(s) is an instrumental to control the amount of non-radiative recombination centers used to trap the optically excited carriers generated in the absorption region.

Owner:OPTOELECTRONICS RES CENT

Transistor laser, and manufacturing method thereof

ActiveCN104485578AImprove performanceAvoid blockingLaser detailsLaser active region structurePower flowSelective leaching

The invention discloses a transistor laser, and a manufacturing method thereof. The method includes the following steps: a substrate is selected; a buffer layer, a lower collector layer, a collector layer, a base layer and a current blocking layer are grown in sequence; part of current blocking layer materials are selectively etched; an active layer, an emitter layer and a contact layer are grown; an emitter ridge waveguide is etched until reaching the current blocking layer; the current blocking layer between base layer materials of the device and active layer materials of the device can serve as an emitter waveguide etching stop layer, so as to achieve high-precision control of the waveguide height. The current blocking layer materials below the emitter ridge waveguide are selectively etched, so as to limit lateral diffusion of carriers, and help reduce non-radiative recombination of the carriers on the side wall of an active area. These measures can remarkably improve the performances of the device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

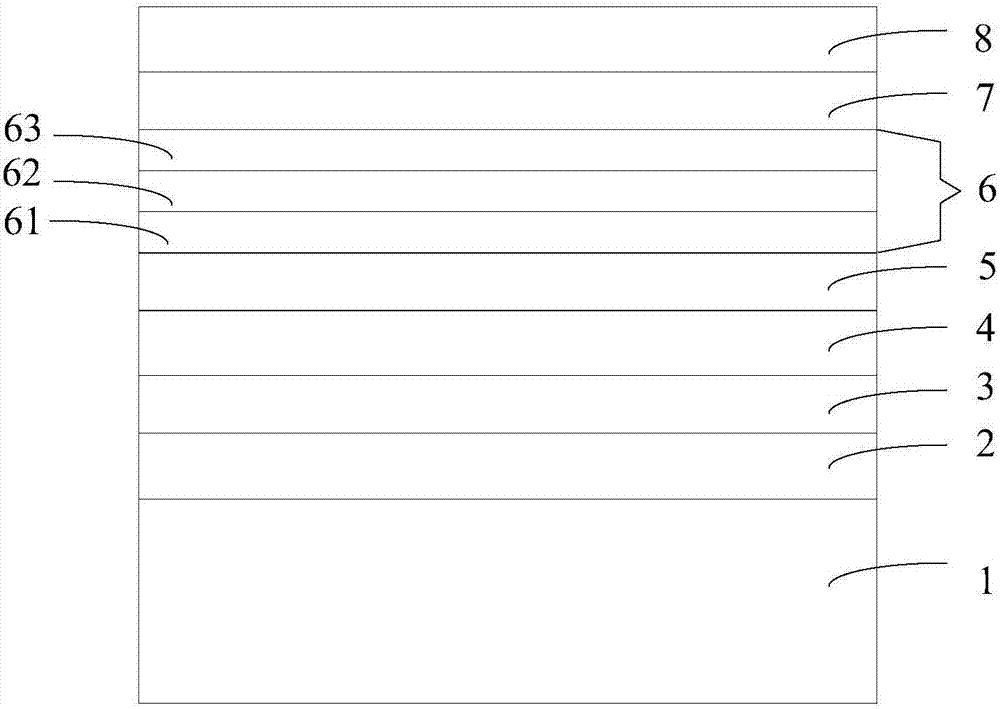

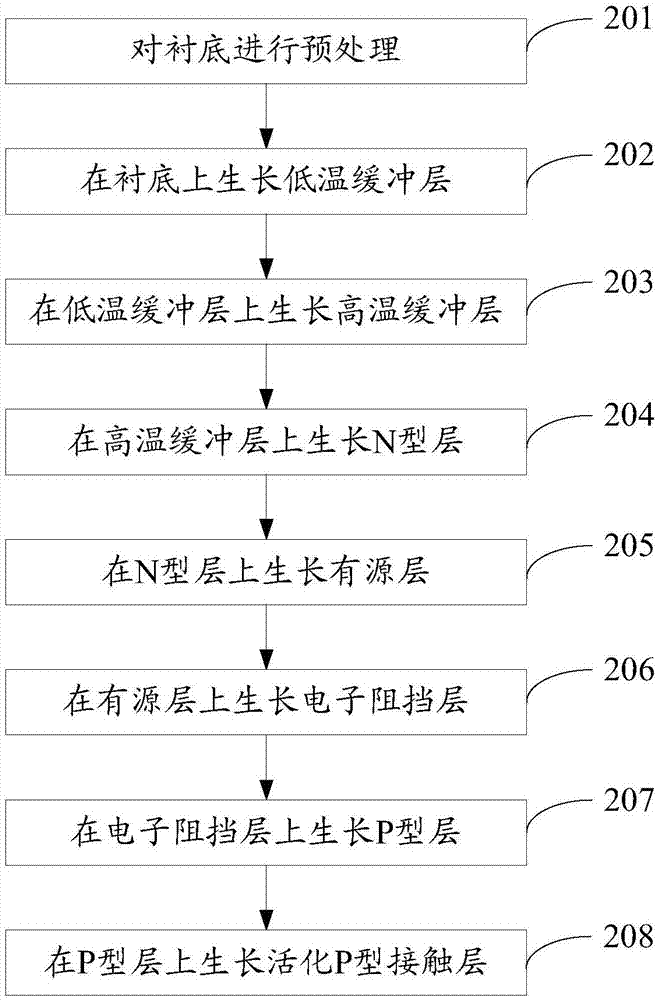

Light emitting diode and manufacturing method thereof

ActiveCN107195739AIncrease the number ofImprove luminous efficiencySemiconductor devicesElectron holeElectron blocking layer

The invention discloses a light emitting diode and a manufacturing method thereof, and belongs to the technical field of a semiconductor. An electron baffle layer of the light emitting diode comprises three sub-layers, wherein the three sub-layers comprise a first sub-layer, a second sub-layer and a third sub-layer which are sequentially grown, the first sub-layer comprises an AlGaN / InGaN superlattice layer with (n+1) periods, the second sub-layer comprises an AlGaN / InGaN superlattice layer with n periods, the third sub-layer comprises an AlGaN / InGaN superlattice layer with (n-1) periods, InGaN layers in the first sub-layer, the second sub-layer and the third sub-layer are all doped with Mg, and n is more than or equal to 3 but less than or equal to 6. The electron baffle layers are divided into three superlattice sub-layers with different doping and same structure to form three segments of baffle layers, so that non-radiative recombination due to electrons leaked to a P layer is reduced as much as possible; and moreover, the periods of the superlattices of each sub-layer in the three sub-layers are gradually reduced according to 1, the electrons can be blocked better, meanwhile, not many holes can be blocked, and the luminous efficiency of a light emitting diode crystal is further improved.

Owner:HC SEMITEK SUZHOU

Method for deactivation of semiconductor laser cavity surface

InactiveCN1670254AReduce difficultyReduce manufacturing costVacuum evaporation coatingSputtering coatingVacuum chamberImpurity

The invention belongs to the semiconductor laser field. It comprises the following steps: cleaving the semiconductor laser to ropes in the air, then loading a fixture and putting it into an electron-beam vapor vacuum chamber; ion precleaning, that is to remove the oxidant and impurity substance in the cleaved cavity surface and the non-radiative recombination center as formed surface state and interface state with low energy ion current, which is less than 100eV , in the air of the electron-beam vapor vacuum chamber; ion precleaning the front cavity surface(4) for 30 seconds to 6 minutes; depositing broad forbidden band low absorbing material such as ZnSe or ZnS on the front cavity surface(4) to be an inactivating blocking layer(3) in the way of electron-beam vapor deposition; plating reflection reducting coating(1) on the front cavity surface(4); ion precleaning the rear cavity surface(5) from the back of the fixture for 30 seconds to 6 minutes; depositing ZnSe or ZnS on the rear cavity surface(5) in the way of electron-beam vapor deposition; plating high negative coating(2) on the rear cavity surface(5). The invented inactivating film is of stable performance, improved reliability, simple preparation, which can be used in lasers with different wave lengths or structures.

Owner:BEIJING UNIV OF TECH

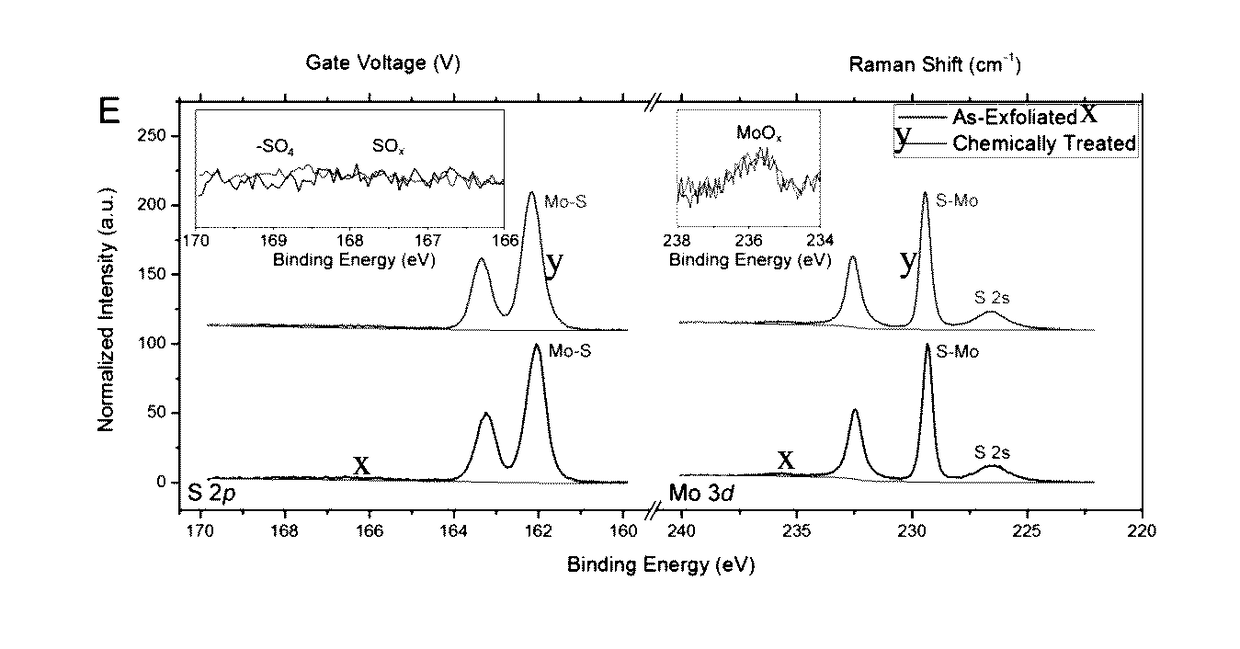

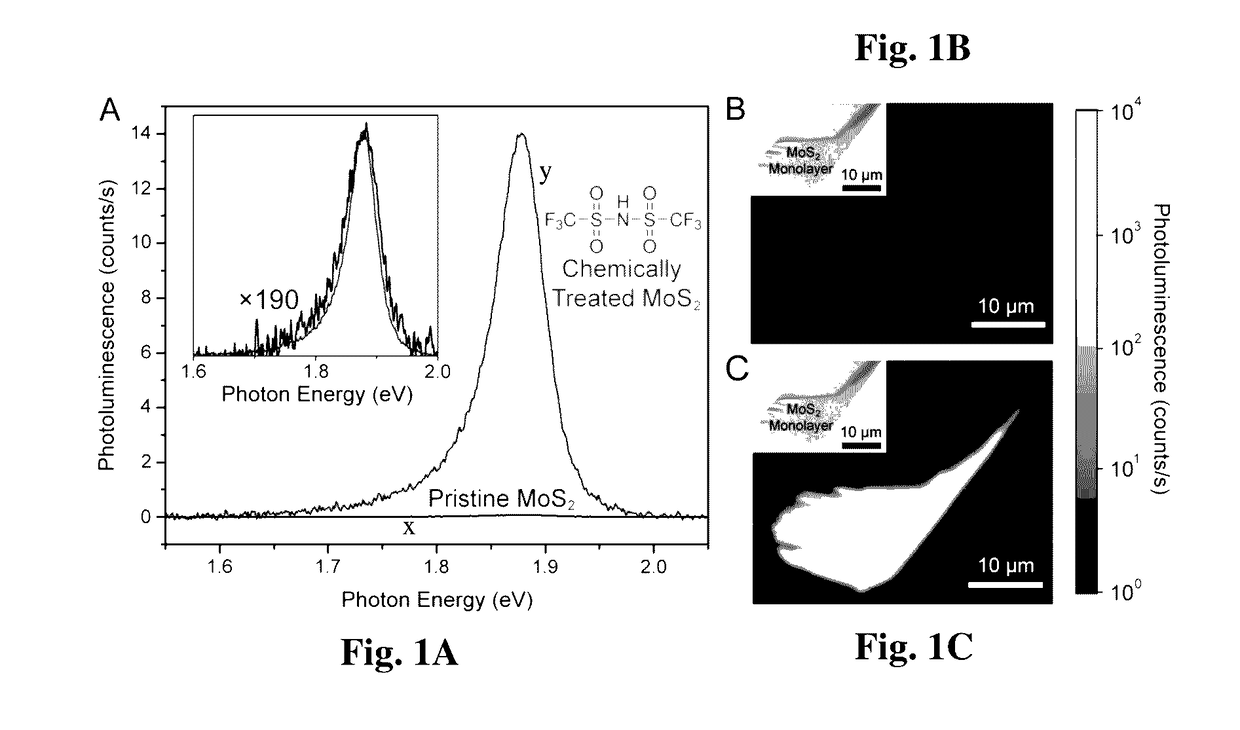

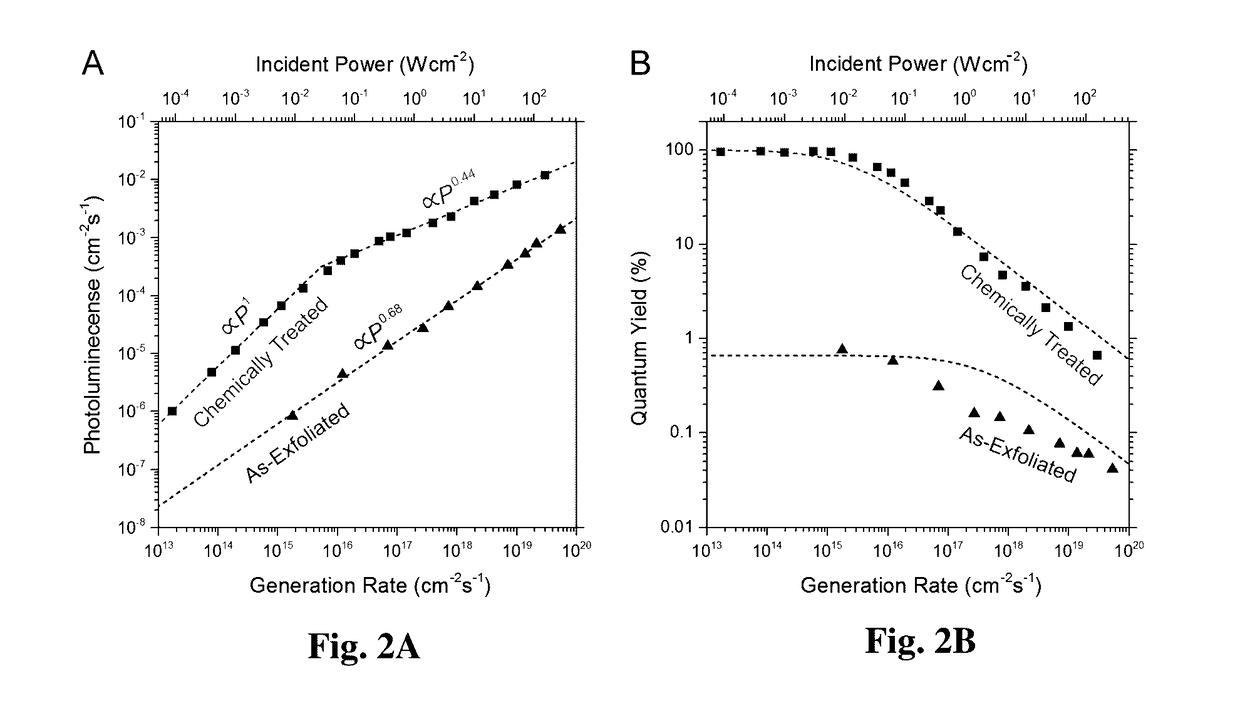

Near-Unity Photoluminescence Quantum Yield in MoS2

ActiveUS20170110338A1Laser detailsFinal product manufactureChemical treatmentLuminescence quantum yield

Two-dimensional (2D) transition-metal dichalcogenides have emerged as a promising material system for optoelectronic applications, but their primary figure-of-merit, the room-temperature photoluminescence quantum yield (QY) is extremely poor. The prototypical 2D material, MoS2 is reported to have a maximum QY of 0.6% which indicates a considerable defect density. We report on an air-stable solution-based chemical treatment by an organic superacid which uniformly enhances the photoluminescence and minority carrier lifetime of MoS2 monolayers by over two orders of magnitude. The treatment eliminates defect-mediated non-radiative recombination, thus resulting in a final QY of over 95% with a longest observed lifetime of 10.8±0.6 nanoseconds. Obtaining perfect optoelectronic monolayers opens the door for highly efficient light emitting diodes, lasers, and solar cells based on 2D materials.

Owner:RGT UNIV OF CALIFORNIA

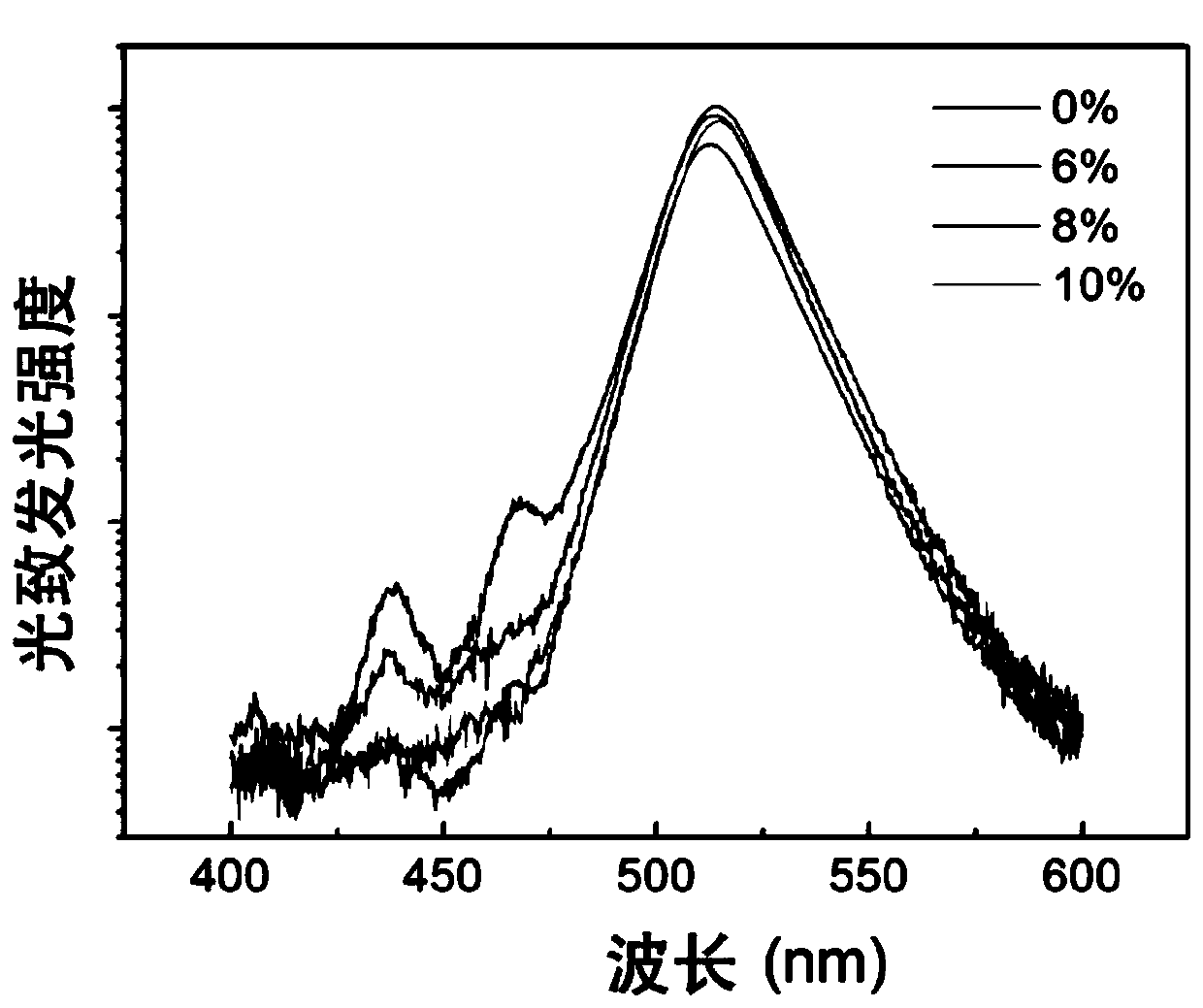

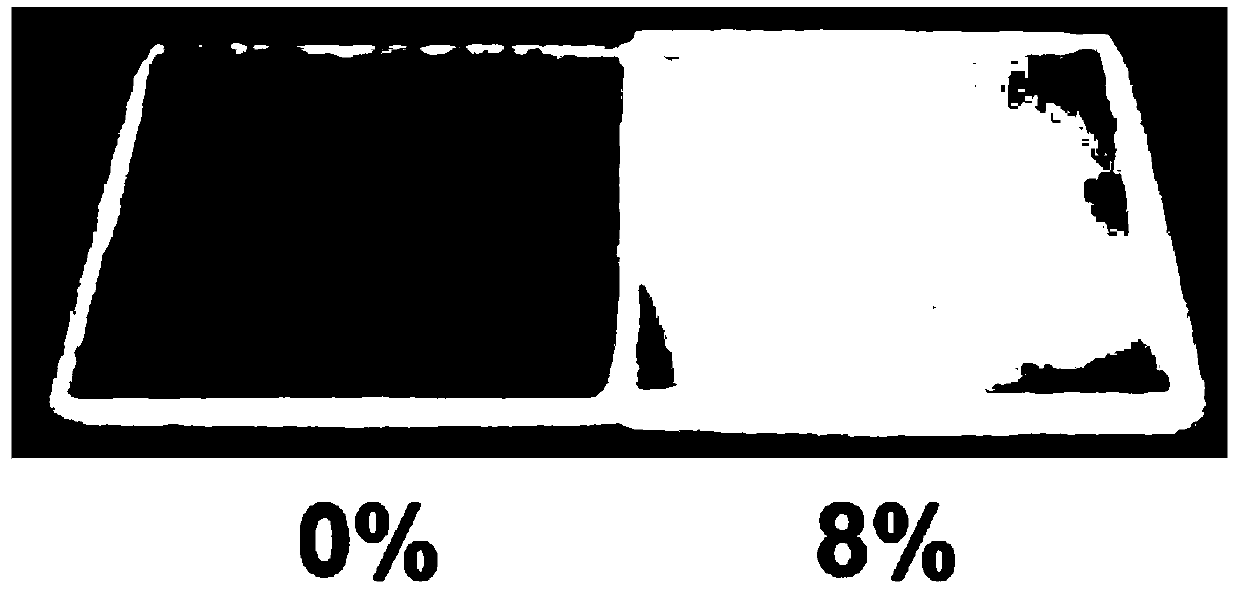

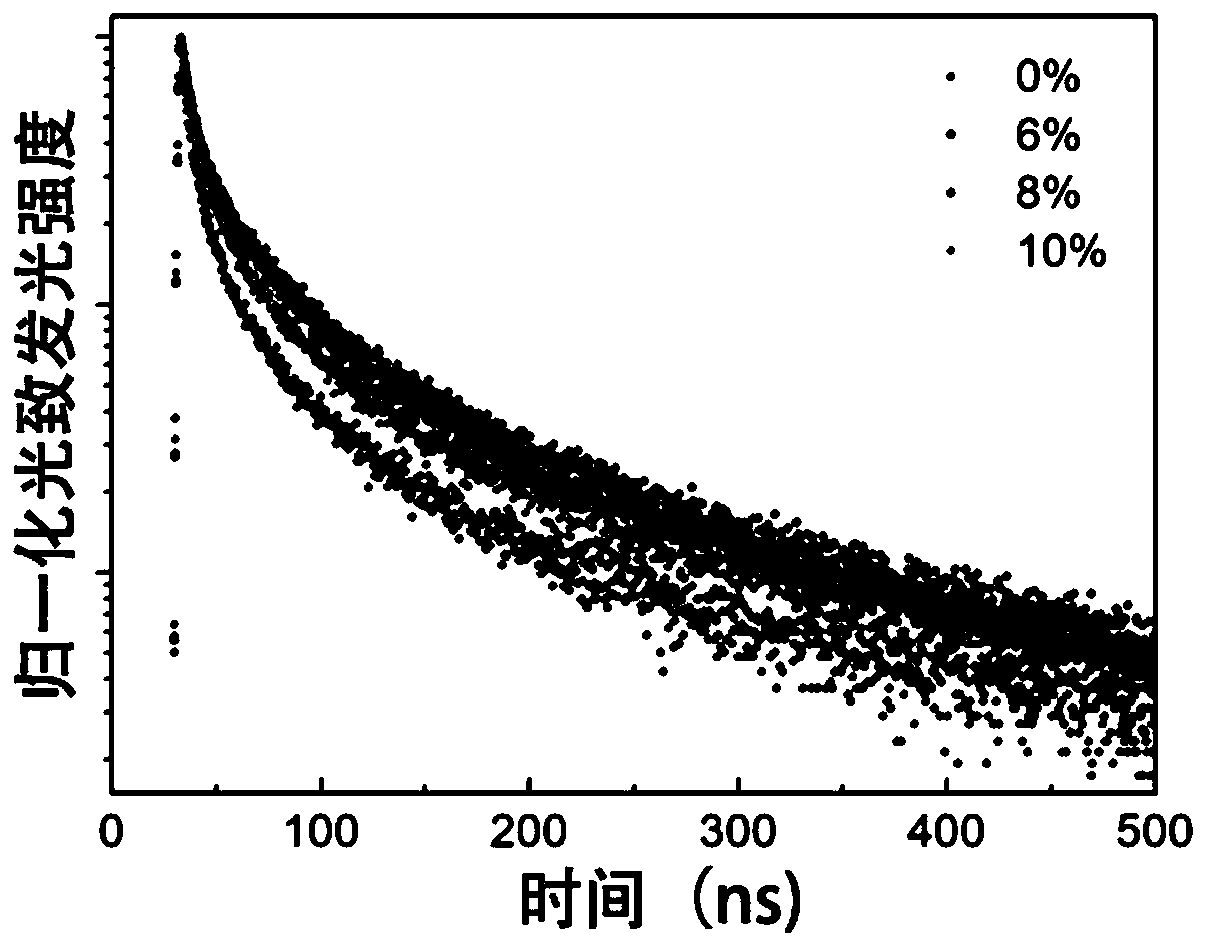

Preparation method of low-defect quasi-two-dimensional perovskite film based on methanesulfonic acid negative ion induction

ActiveCN110305660AEfficient deliveryEffective delivery pathLuminescent compositionsPhotovoltaic energy generationFilm baseMetal halides

The invention discloses a preparation method of a low-defect quasi-two-dimensional perovskite film based on methanesulfonic acid negative ion induction. According to the method, methanesulfonic acid (MeS) negative ions are led in an L2An-1MnX3n+1 perovskite precursor to adjust phase compositions, so that a more effective energy transfer way is generated. Crystal boundary and surface defect inactivation is achieved by the MeS negative ions, and non-radiative recombination is effectively restrained. The service life of an exciton of the prepared quasi-two-dimensional perovskite film is obviouslyprolonged, and three-dimensional perovskite crystal particles are obviously increased. CsMeS is added into quasi-two-dimensional metal halide perovskite precursor solution to adjust perovskite phasecompositions, so that more three-dimensional perovskite crystal particles are generated as compared with a traditional method, and the more effective energy transfer way is generated. According to themethod, mixing of perovskite crystal lattices in the used CsMeS is omitted, the crystal lattices only exist on the surfaces of the perovskite crystal lattices, crystal boundary and surface defect inactivation can be achieved by MeS negative ions in the CsMeS, and non-radiative recombination is effectively restrained.

Owner:SHANGHAI UNIV

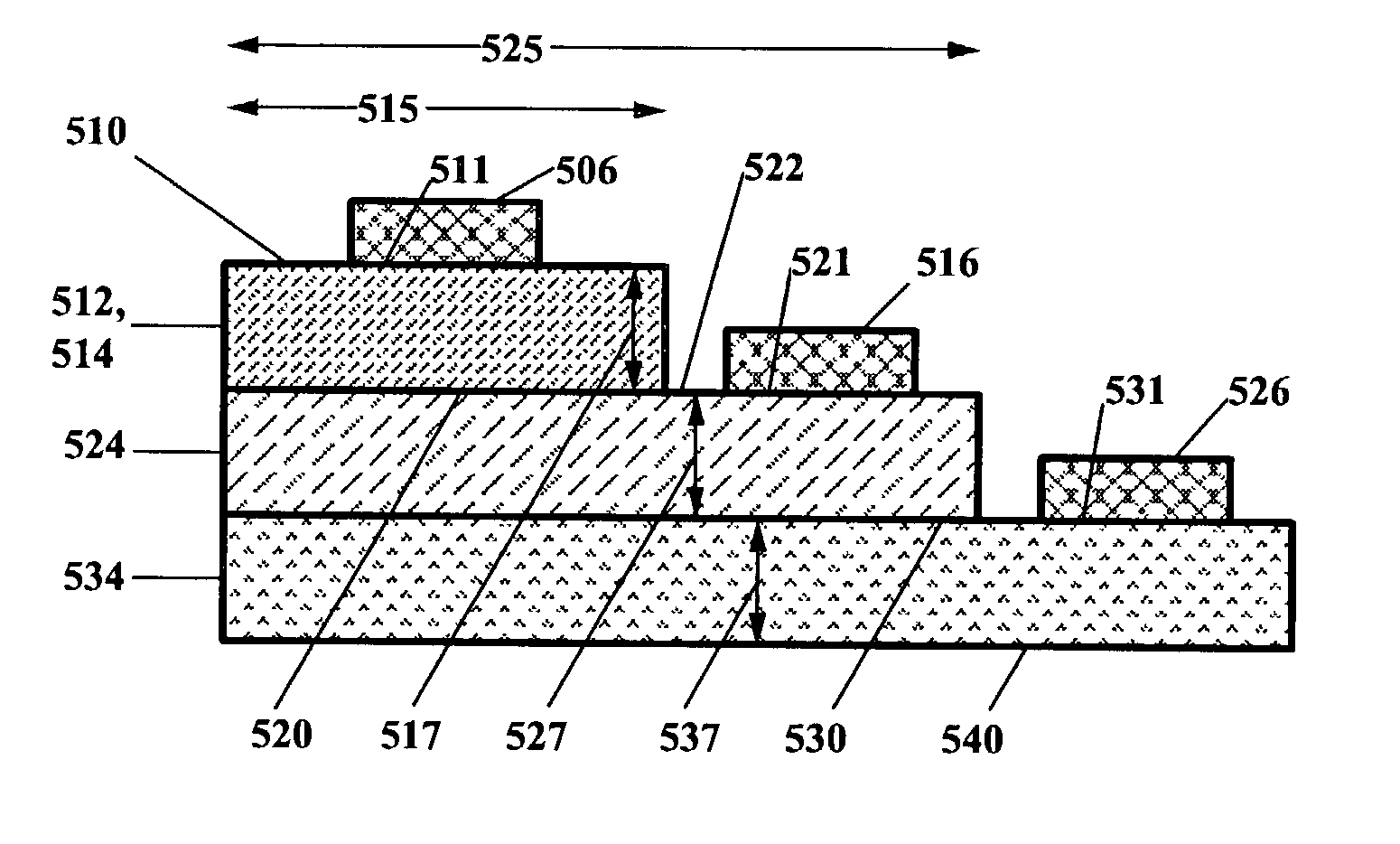

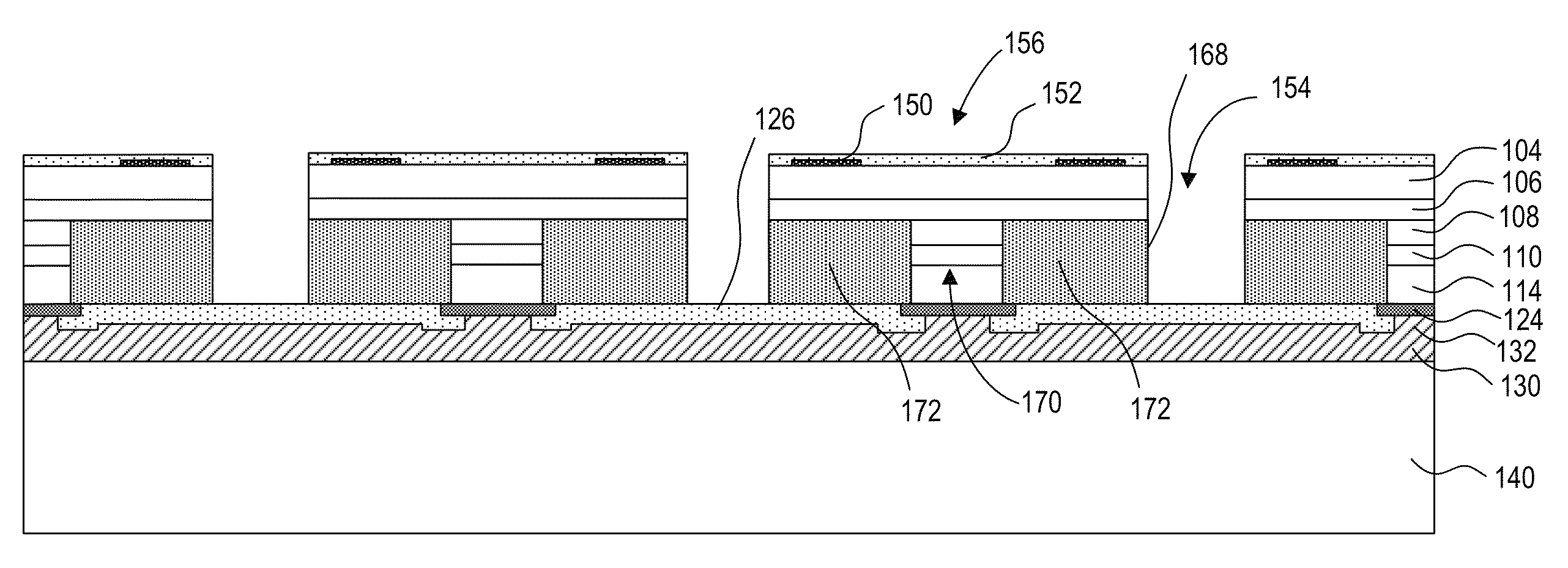

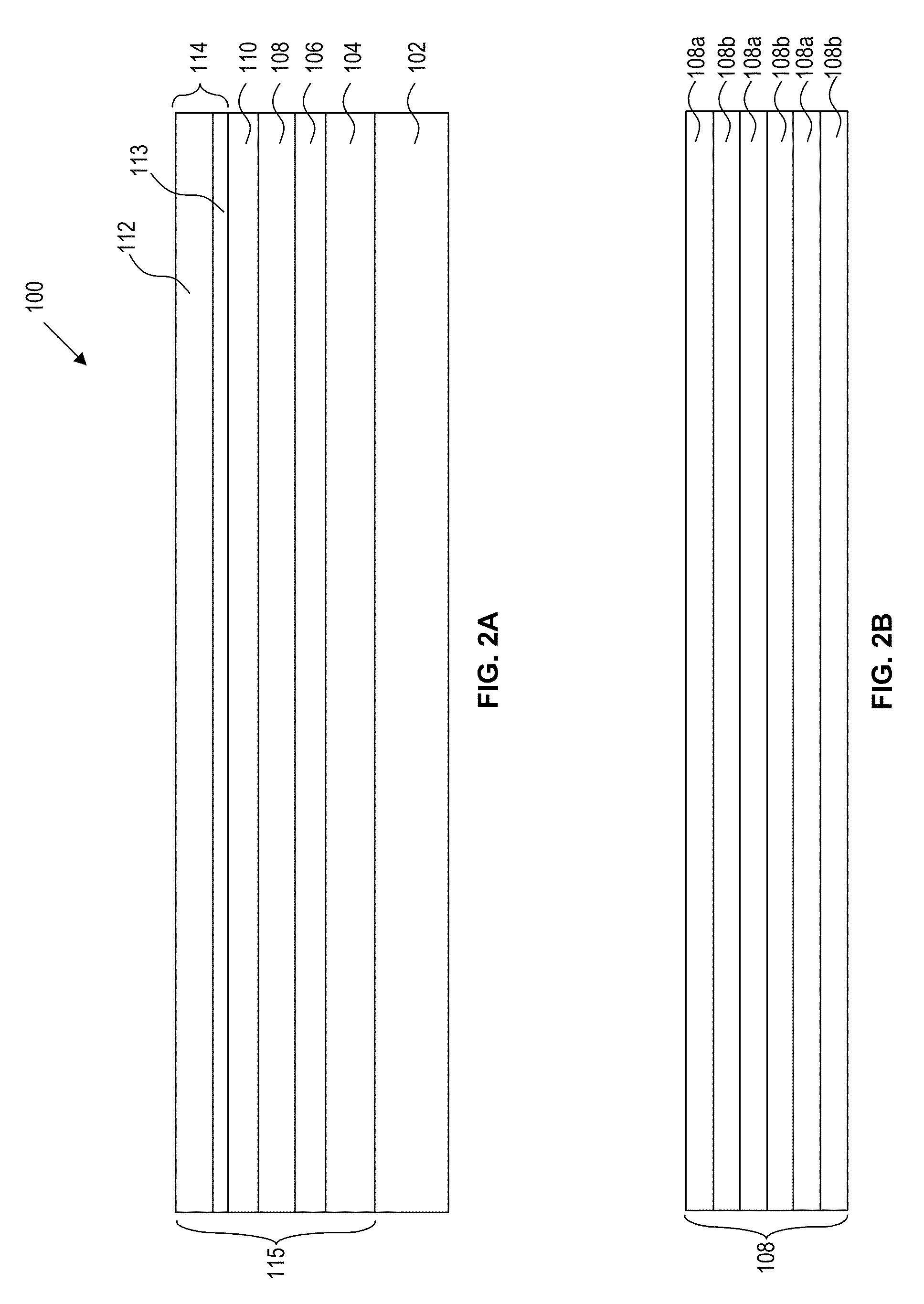

LED with internally confined current injection area

ActiveUS9450147B2Static indicating devicesSemiconductor/solid-state device detailsDiffusionEdge effects

Methods and structures for forming arrays of LED devices are disclosed. The LED devices in accordance with embodiments of the invention may include an internally confined current injection area to reduce non-radiative recombination due to edge effects. Several manners for confining current may include etch removal of a current distribution layer, etch removal of a current distribution layer and active layer followed by mesa re-growth, isolation by ion implant or diffusion, quantum well intermixing, and oxide isolation.

Owner:APPLE INC

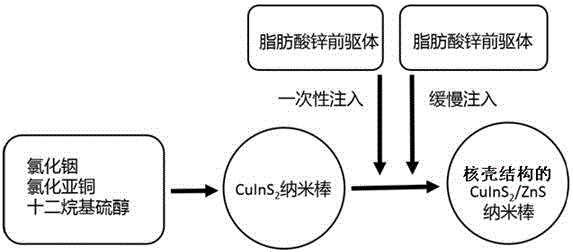

Core-shell structured CuInS2/ZnS nanorod and preparation method thereof

ActiveCN106544003AAbsorbentLarge polarized emissionNanoopticsLuminescent compositionsLight energyDissolution

The invention discloses a core-shell structured CuInS2 / ZnS nanorod and a preparation method thereof. The preparation method comprises the steps of mixing indium chloride, cuprous chloride and lauryl mercaptan to obtain a CuInS2 nanorod; mixing and heating zinc fatty acid, lauryl mercaptan and 1-octadecene to obtain zinc fatty acid precursor; rapidly filling the obtained zinc fatty acid precursor into CuInS2 nanorod solution then slowly filling in the rest of the zinc fatty acid precursor for reaction; performing repeated dissolution and precipitation on reaction products and then performing centrifugal purification to obtain the core-shell structured CuInS2 / ZnS nanorod. The core-shell structured CuInS2 / ZnS nanorod obtains a large light energy absorbing section for linear polarized absorption and polarized emission and meanwhile can inhibit Auger non-radiative recombination and achieves relatively high illumination efficiency. Meanwhile, the high-quality core-shell structured CuInS2 / ZnS nanorod can be applied to lighting and display.

Owner:TCL CORPORATION

Light-emitting enhancement type electron beam pumping ultraviolet light source and preparation method thereof

ActiveCN105846310AIncrease reflectionImprove extraction efficiencyLaser active region structureExcitation process/apparatusPotential wellUltraviolet lights

Owner:PEKING UNIV

Method for improving extended wavelength gallium indium arsenide detector etching damage

InactiveCN107994094ARepair damageQuality improvementFinal product manufactureSemiconductor devicesIndium arsenideMaterial quality

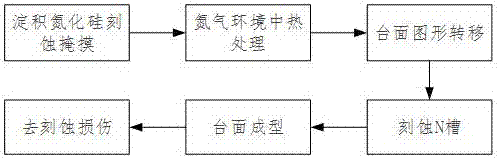

The invention discloses a method for improving extended wavelength gallium indium arsenide detector etching damage which is provided with a whole set of chip preparation etching processes. The methodincludes the steps: (1) depositing a mask etched by silicon nitride; (2) performing heat treatment in the nitrogen environment; (3) transferring table top images; (4) etching an N groove; (5) forminga table top; (6) removing etching damage. The method has the advantages that the mask etched by the silicon nitride is deposited, the heat treatment is performed in the nitrogen environment, materialdamage can be repaired, complex center density is reduced, material quality is improved, dark current of devices is reduced, hole carrier density can be increased, P-electrode ohmic contact stabilityis facilitated, resistance is reduced, a table top forming process includes gas is etched by the aid of chlorine methane, hydrogen decomposed by the methane in the plasma etching process can passivatedangling bonds formed by etching, and non-radiative recombination center density in materials is reduced. According to an etching damage removing process, damage layers of etching surfaces can be removed, the non-radiative recombination center density is reduced, subsequent passivation effects are enhanced, and the method is applicable to preparation of a high-performance short wave infrared gallium indium arsenide detector.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

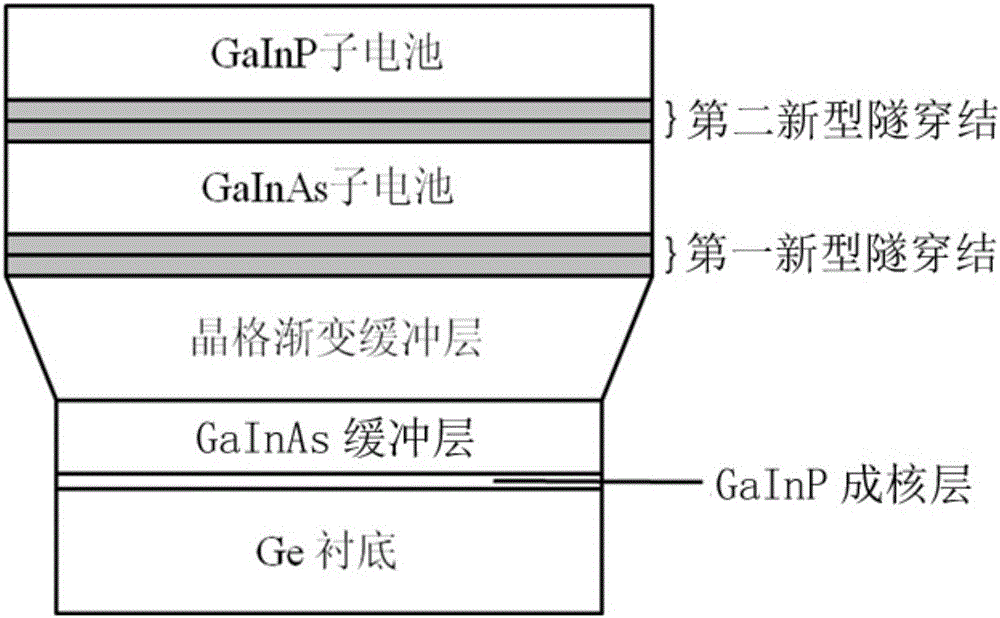

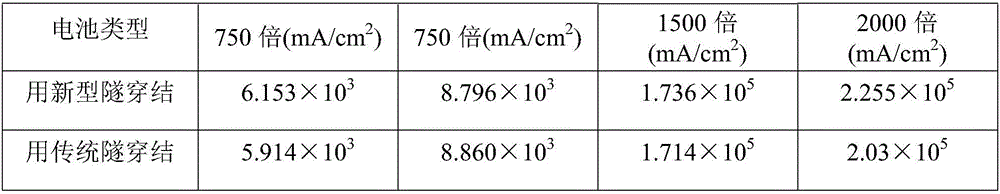

Lattice mismatch solar cell containing novel tunneling junction and preparation method thereof

ActiveCN106024924AImprove crystal qualityActs as a dislocation barrierFinal product manufacturePhotovoltaic energy generationIndiumLattice mismatch

The invention discloses a lattice mismatch solar cell containing a novel tunneling junction and a preparation method thereof. A Ge monocrystal is used as a substrate, and a GaInP nucleation layer, a GaInAs buffer layer, a lattice gradient buffer layer, a first novel tunneling junction, a GaInAs sub cell, a second novel tunneling junction and a GaInP sub cell are grown on the surface of the substrate sequentially from bottom to top. The first novel tunneling junction and the second novel tunneling junction include a layer of degenerate p-type gallium indium nitrogen arsenide (Ga<1-y>In<y>N<x>As<1-x>) and a layer of degenerate n-type gallium indium arsenide (Ga<1-z>In<z>As), the lattice constants of the two layers of materials are respectively consistent with the materials of the adjacent semiconductor layers or the mismatching degree is less than 3%, and the thickness of each layer is 5-100nm. The novel tunneling junction adopted in the invention has better conductivity and light transmission than general tunneling junctions. More importantly, as a rigid material, the novel tunneling junction can filter a lot of threading dislocation and mismatch dislocation, reduce non-radiative recombination, prolong the service life of minority carriers and improve the photoelectric conversion efficiency.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

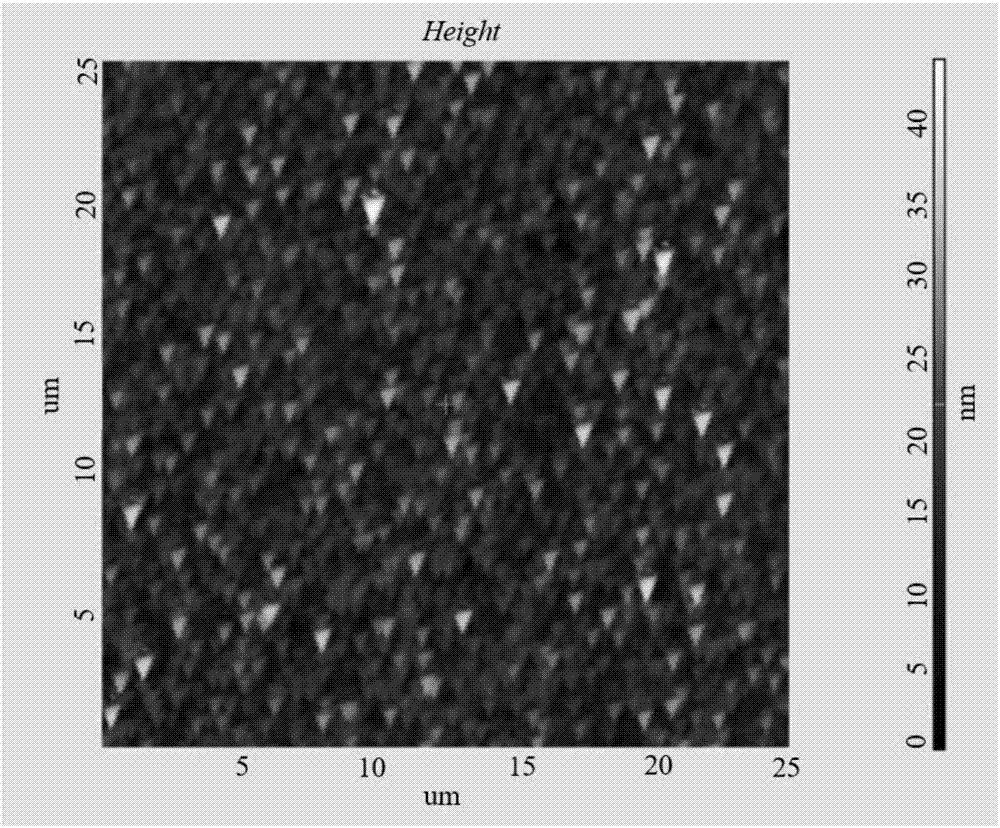

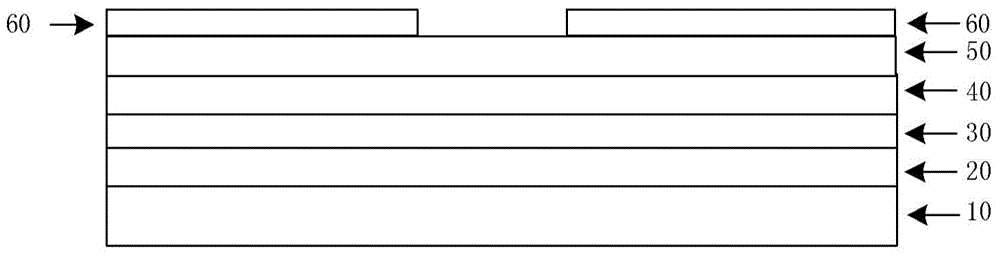

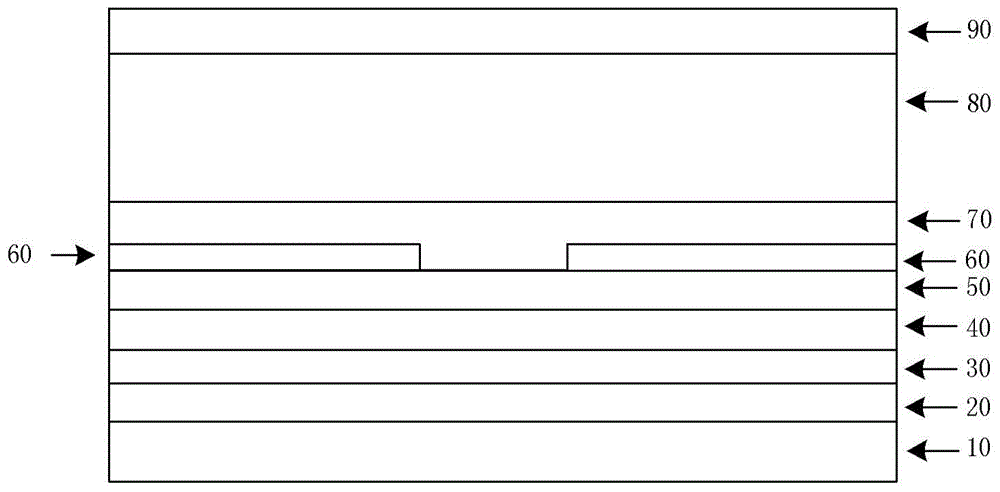

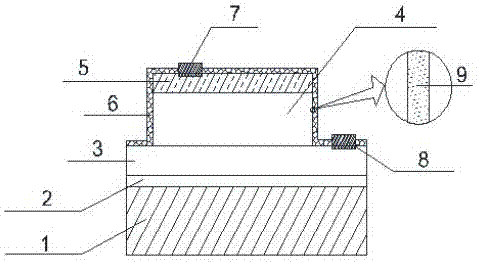

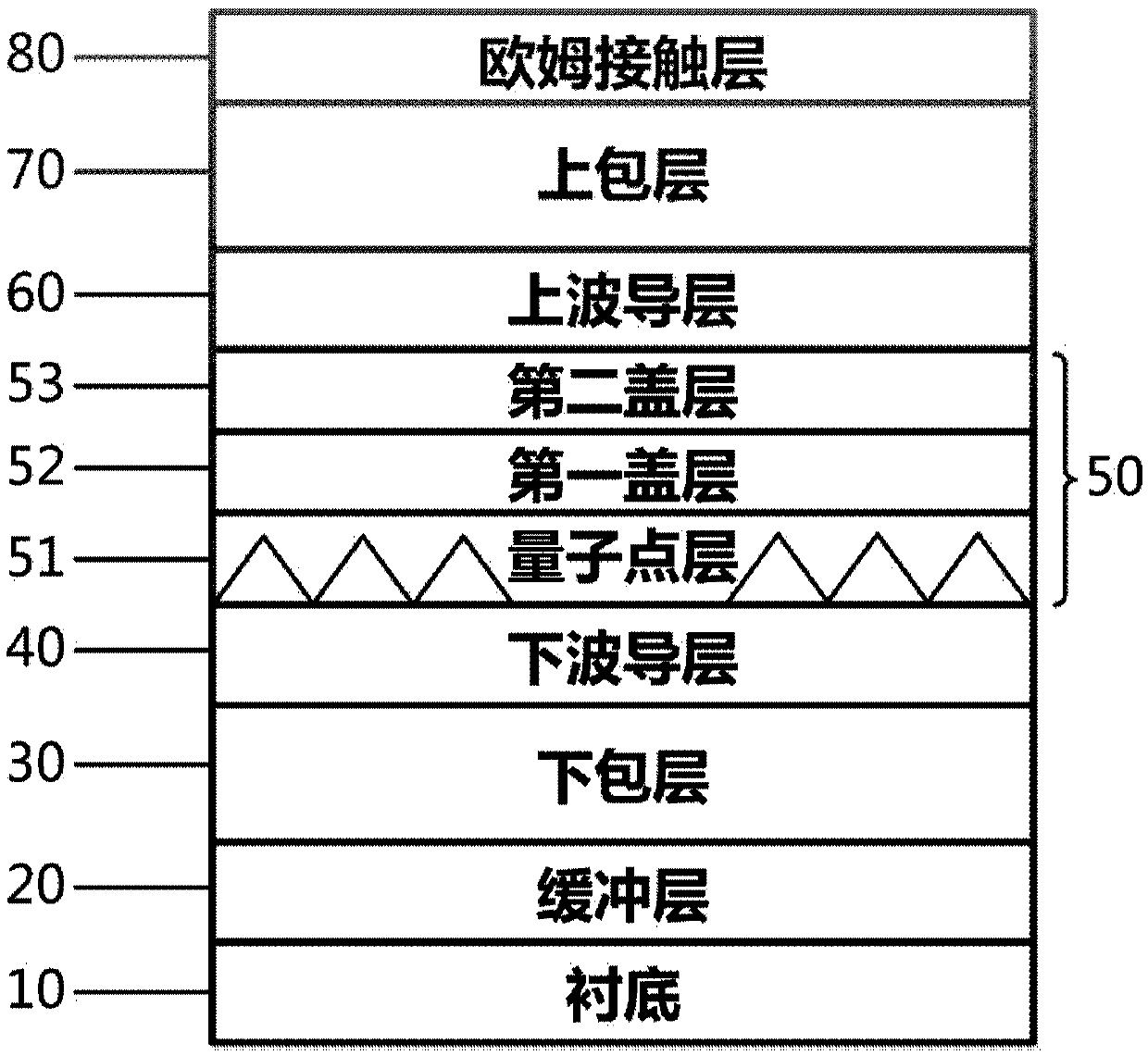

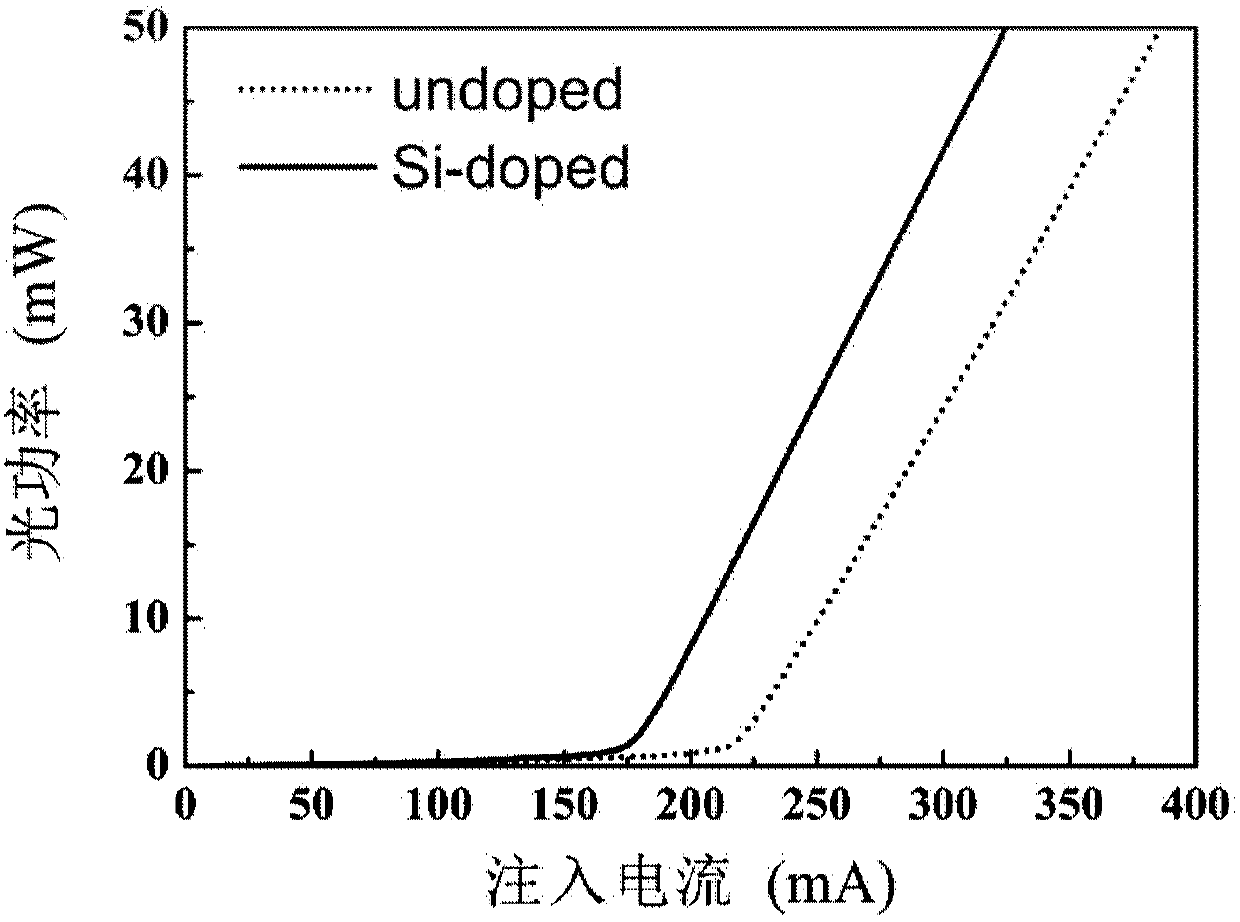

Si-doped InAs/GaAs quantum dot laser and preparation method thereof

InactiveCN107611780ALower threshold currentImprove performanceLaser detailsSemiconductor lasersOptical propertyOhmic contact

The invention discloses a Si-doped InAs / GaAs quantum dot laser and a preparation method thereof. The Si-doped InAs / GaAs quantum dot laser is characterized by comprising a quantum dot active region (50), wherein the quantum dot active region (50) comprises a Si-doped quantum dot layer (51); and according to the preparation method of the quantum dot laser, a buffer layer (20), a lower cladding layer(30), a lower waveguide layer (40), the quantum dot active region (50), an upper waveguide layer (60), an upper cladding layer (70) and an ohmic contact layer (80) are sequentially grown on a substrate (10) by adopting an MBE epitaxial growth method. According to the quantum dot laser, a non-radiative recombination center near quantum dots is effectively passivated through introducing Si atoms and the optical property of a quantum dot material is strengthened; and meanwhile, threshold current of a laser device can be reduced through electrons introduced by the Si atoms and the performance ofthe device can be improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

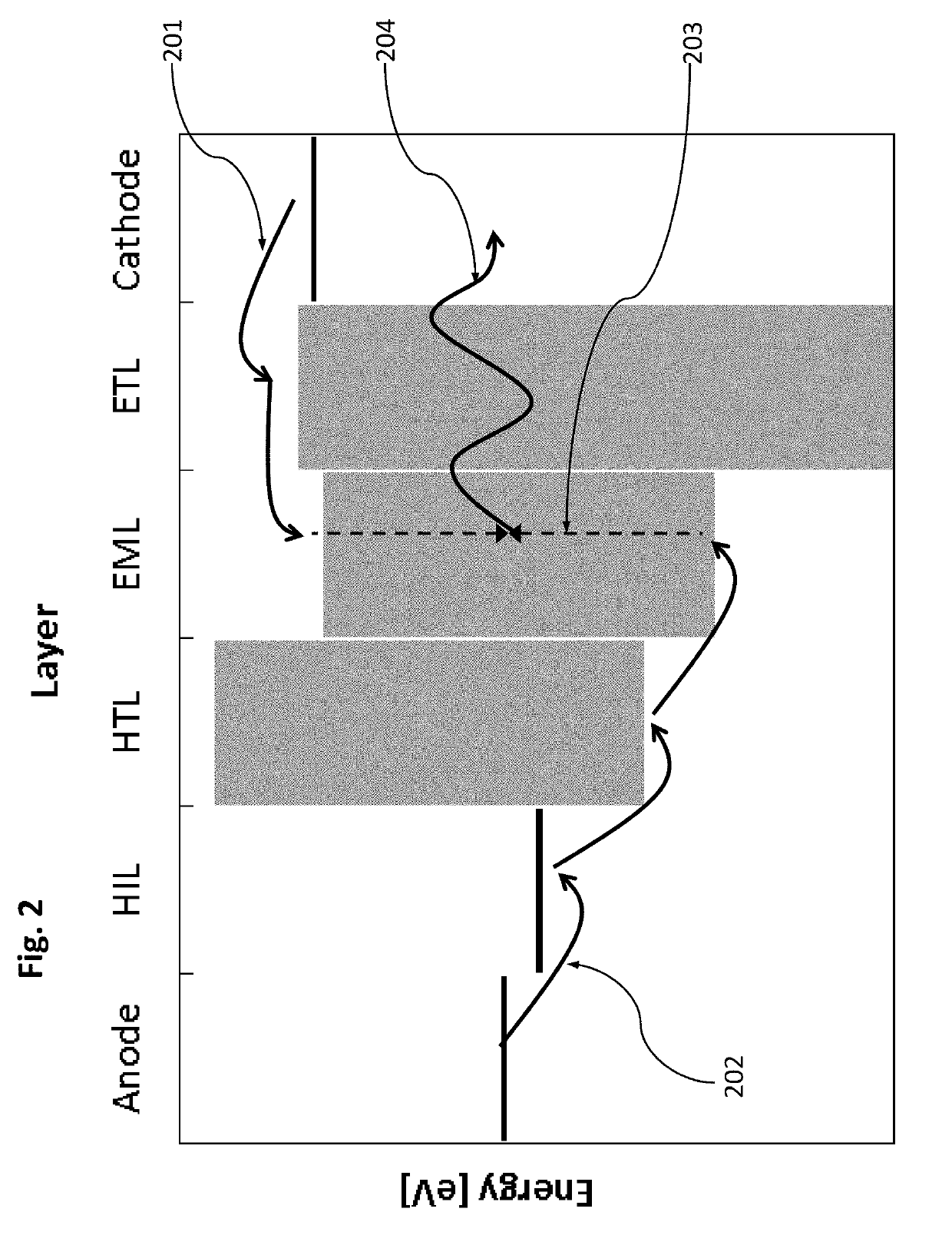

Light-emitting device with mixed nanoparticle charge transport layer

ActiveUS20190296257A1Wide rangeEffectiveMaterial nanotechnologySolid-state devicesCharge injectionTransport layer

A light-emitting device is optimized for radiative recombination and minimizes non-radiative recombination. The light-emitting device includes an emissive layer, a first electrode and a second electrode from which charges are generated, a first charge transport layer that injects charges from the first electrode into the emissive layer, and a second charge transport layer that injects charges from the second electrode into the emissive layer. At least one of the charge transport layers includes a mixture of a first nanoparticle population and a second nanoparticle population, and the first nanoparticle population and the second nanoparticle population are conductive nanoparticles that are energetically non-aligned as between the first nanoparticle population and the second nanoparticle population. Nanoparticles of the first nanoparticle population and the second nanoparticle population are energetically non-aligned with each other by being made of different materials, by having nanoparticles of different sizes, and / or by having nanoparticles of different shapes.

Owner:SHARP KK

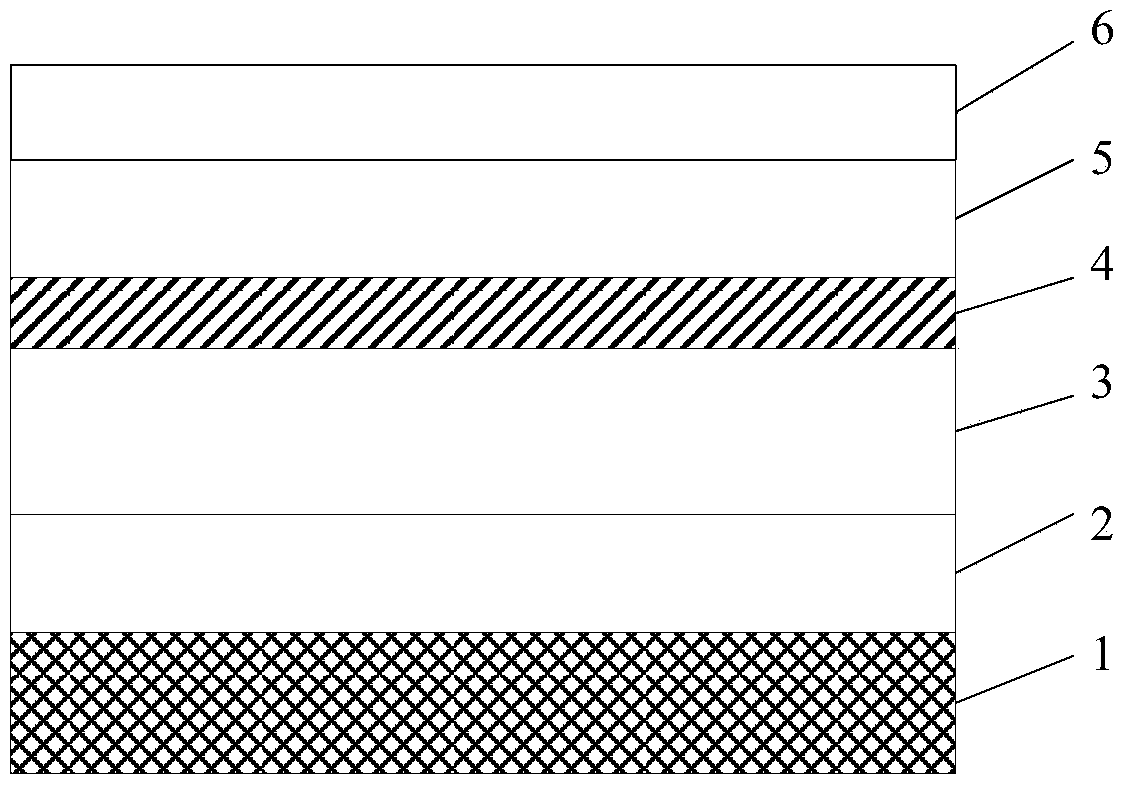

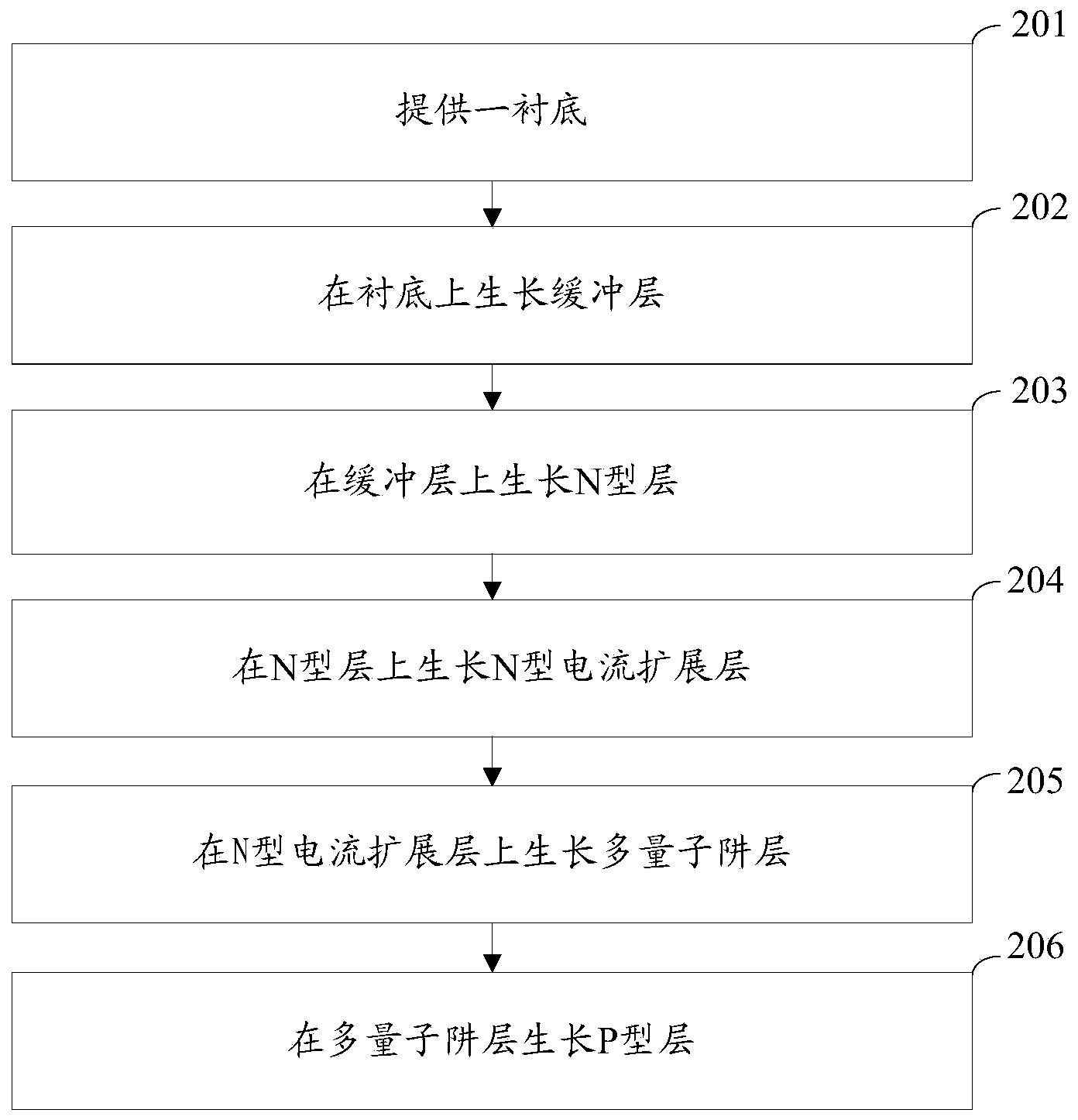

Epitaxial wafer of GaN-based light-emitting diode and preparing method thereof

ActiveCN104300064AReduce doping concentrationIncrease the doping concentrationSemiconductor devicesDelta dopingQuantum well

The invention discloses an epitaxial wafer of a GaN-based light-emitting diode and a preparing method of the epitaxial wafer, and belongs to the field of light-emitting diodes. The preparing method includes the steps that a substrate is provided; a buffer layer and an N-type layer sequentially grow on the substrate, an N-type current expanding layer, a multi-quantum-well layer and a P-type layer sequentially grow on the N-type layer, the N-type current expanding layer is a GaN layer adopting a delta doping technology for growth, the doping concentration of the N-type current expanding layer is smaller than that of the N-type layer, starting from one side of the N-type layer, the doping concentration of the N-type current expanding layer is kept unchanged or reduced gradually, and the doping concentration of the portion, adjacent to one side of the multi-quantum-well layer, of the N-type current expanding layer is zero. The current expanding layer grows by adopting the delta doping technology, the carrier concentration is high, compensation is small, and the device is good in heat stability; the undoped GaN layer is introduced into the position close to an active area to ensure transverse expansion of currents and reduce forward voltage drop, the service life is prolonged, and the fact that defects caused by doping extend to the active area and a non-radiative recombination center is reduced.

Owner:HC SEMITEK SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com