Si-doped InAs/GaAs quantum dot laser and preparation method thereof

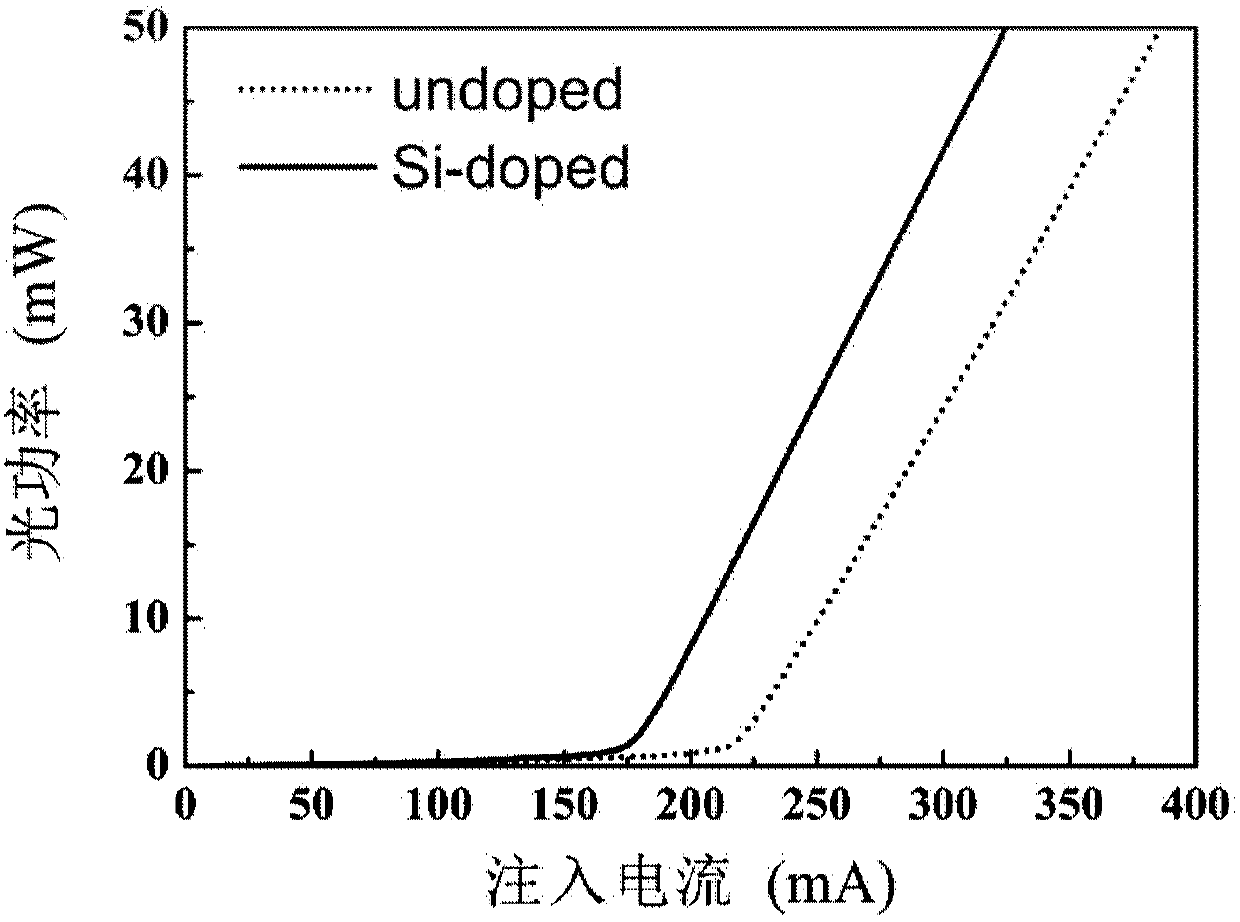

A quantum dot and laser technology, which is applied in the field of Si-doped InAs/GaAs quantum dot laser and its preparation, can solve the problems of size, shape distribution uniformity and difficult control of density, and achieve the effect of reducing threshold current and improving device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

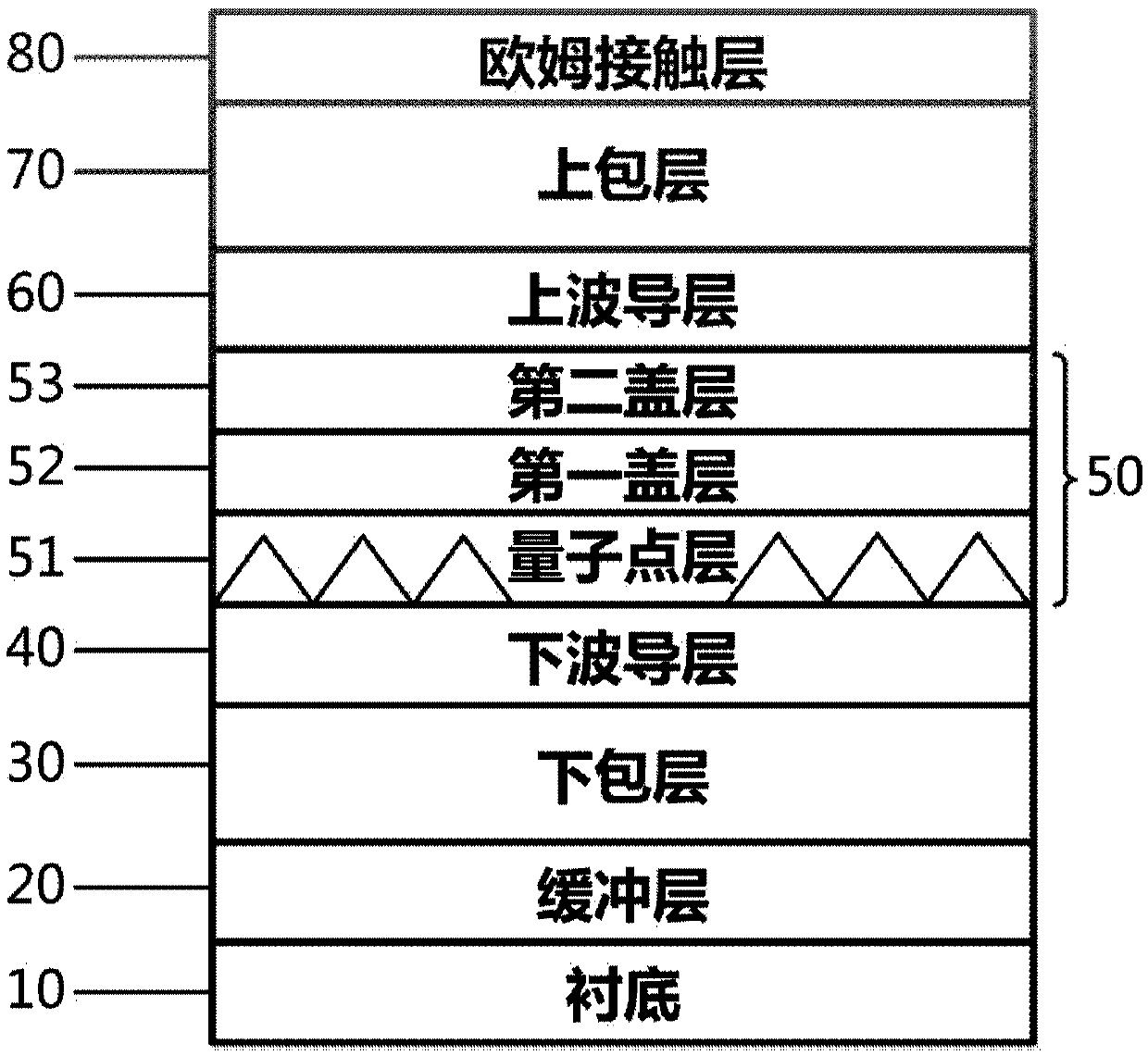

[0090] (1) Take a substrate 10, which is an n+ type GaAs substrate with a crystal orientation of (100), a doping element of Si, and a doping concentration of (0.5-5)×10 18 cm -3 ;

[0091] (2) Epitaxially grow a layer of GaAs buffer layer 20 on the above-mentioned GaAs substrate 10, the buffer layer growth thickness is 0-800nm, it is n-type doped, the doping element is Si element, and the doping concentration is (0.5- 5)×10 18 cm -3 ;

[0092] (3) Epitaxially grow the AlGaAs lower cladding layer 30 on the above-mentioned GaAs buffer layer 20, the growth thickness is 500-2000nm, and perform n-type doping on it, the doping element is Si element, and the doping concentration is (0.1-5)× 10 18 cm -3 ;

[0093] (4) epitaxially growing the GaAs lower waveguide layer 40 on the above-mentioned AlGaAs lower cladding layer 30, with a growth thickness of 50-200 nm;

[0094] (5) Epitaxially grow a Si-doped InAs quantum dot layer 51 on the above-mentioned GaAs lower waveguide layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com