GaN-based laser unit and super-radiation light-emitting diode as well as manufacturing method thereof

A superluminescence and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of reduced current injection efficiency, deterioration of device performance, small lateral divergence angle of light spot, etc., to improve device reliability and avoid engraving. Etch damage, the effect of eliminating the etching operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

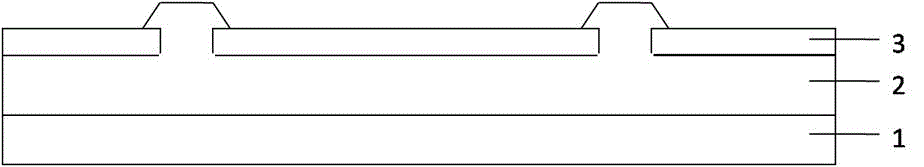

[0051] Embodiment 1 The GaN-based blue laser and superluminescent light-emitting diode structure of this embodiment can refer to Figure 4 , which can be grown and formed by the selective area epitaxy method, which specifically includes the following steps:

[0052] S1: Put the substrate into MOCVD, raise the temperature to about 1080°C, and pretreat the substrate at high temperature for about 5 minutes in a hydrogen atmosphere to remove impurities on the surface of the substrate, and then inject a small amount of NH 3 Nitriding the substrate surface;

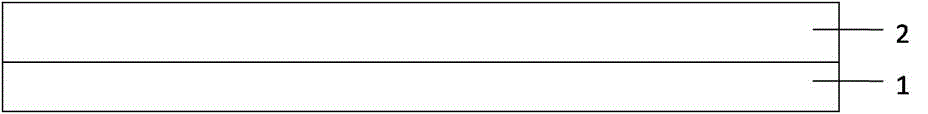

[0053] S2: Cool down to about 530°C, grow a GaN nucleation layer of about 25nm, perform high temperature (about 1000°C) annealing on the GaN nucleation layer, and grow an undoped GaN layer of about 1 μm and n-GaN of about 2 μm at high temperature layer, such as figure 1 shown;

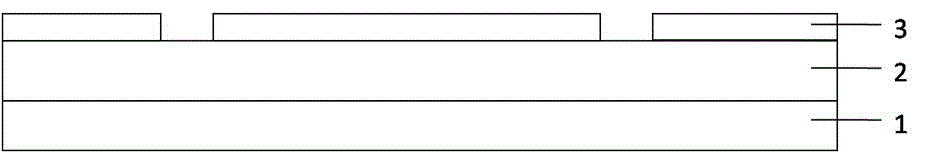

[0054] S3: After the growth is over, take out the epitaxial wafer, and deposit about 200nm of SiO on the surface of the sample by plasma enhanced ch...

Embodiment 2

[0061] Embodiment 2 The GaN-based blue laser and the superluminescent light-emitting diode of this embodiment can be based on Figure 5 The growth and formation of the substrate shown specifically includes the following steps:

[0062] S1: Put the substrate into MOCVD, raise the temperature to about 1080°C, and pretreat the substrate at high temperature for about 5 minutes in a hydrogen atmosphere to remove impurities on the surface of the substrate, and then inject a small amount of NH 3 Nitriding the substrate surface;

[0063] S2: Cool down to about 530°C, grow a GaN nucleation layer of about 25nm, perform high temperature (about 1000°C) annealing on the GaN nucleation layer, and grow an undoped GaN layer of about 1 μm and n-GaN of about 2 μm at high temperature layer, such as figure 1 shown;

[0064] S3: After the growth is over, take out the epitaxial wafer, and deposit about 200nm of SiO on the surface of the sample by plasma enhanced chemical vapor deposition (PECVD)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com