Long wavelength GaNAsBi/GaAs multiple-quantum well laser and manufacturing method thereof

A technology of multiple quantum wells and multiple quantum well structures, applied in the field of semiconductor optoelectronics, can solve problems such as difficulties, and achieve the effects of low production cost, lower threshold current, and improved yield and lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] As a preferred embodiment: the GaNAsBi / GaAs multi-quantum well contains 3 periods, GaAs is used as a barrier layer, GaNAsBi is used as a potential well layer, and a compressive strain of 1% is formed with GaAs, wherein the composition of N is 2.28% , the composition of Bi is 3.25%.

[0060] Preferably, the long-wavelength GaNAsBi / GaAs multi-quantum well laser is epitaxially grown on a GaAs substrate.

[0061] Preferably, the lower confinement layer is an N-type AlGaAs lower confinement layer, which is composed of an N-type AlGaAs layer, and the composition of Al is 15%.

[0062] Correspondingly, the upper confinement layer is a P-type AlGaAs upper confinement layer, which is composed of a P-type AlGaAs layer, and the composition of Al is 15%.

[0063] Correspondingly, the electron blocking layer is a P-type AlGaAs electron blocking layer, located between the AlGaAs upper waveguide layer and the upper confinement layer, and the composition of Al is 20%

[0064] Prefera...

Embodiment 1

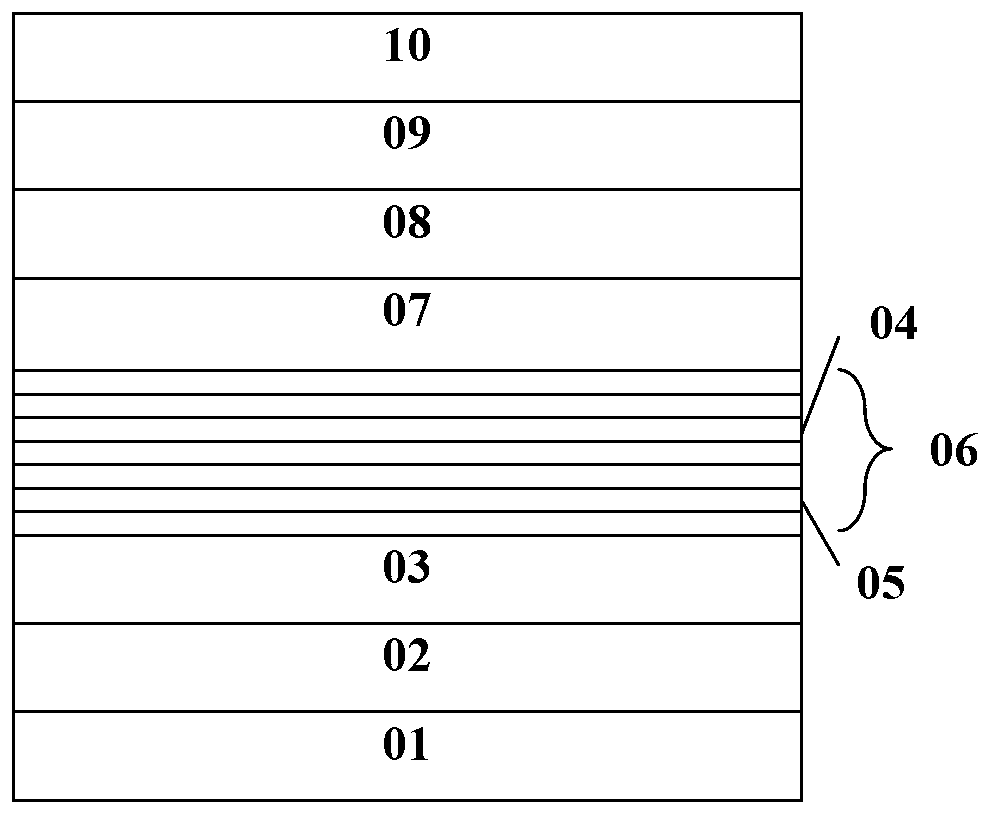

[0090] Embodiment one: if figure 1 , when using AlGaAs as the upper and lower confinement layers, the preparation method of the long-wavelength GaNAsBi / GaAs multi-quantum well laser comprises the following steps:

[0091] (1) grow described long-wavelength GaNAsBi / GaAs multiple quantum well laser with MOCVD method, its structure is as follows figure 1 Shown:

[0092] (1) N-type doping about 2×10 is grown on N-type GaAs substrate 01 18 cm -3 A 0.2 micron AlGaAs layer with an Al composition of 15% forms the lower confinement layer 02;

[0093] (2) grow a 0.1 micron non-doped AlGaAs layer with an Al composition of 8% to form the lower waveguide layer 03;

[0094] (3) Alternately grow 10nm GaAs barrier layer 04 (4 pieces) and 5.5nm GaNAsBi potential well layer 05 (3 pieces) with 1% compressive strain, in which the N component is about 2.28%, and the Bi component is about 3.25% , forming a 3-period multi-quantum well structure to form the active region 06 of the laser;

[009...

Embodiment 2

[0101] Embodiment 2: as figure 1 , when using GaInP as the upper and lower confinement layers, the preparation method of the long-wavelength GaNAsBi / GaAs multi-quantum well laser comprises the following steps:

[0102] (1) Growth of long-wavelength GaNAsBi / GaInP multi-quantum well laser by MOCVD method, its structure is as follows figure 1 Shown:

[0103] (1) On the N-type GaAs substrate 01 grow N-type doped about 2×10 18 cm -3 The 0.2 micron GaInP layer, the Al composition is 52%, forms the lower confinement layer 02;

[0104] (2) grow a 0.1 micron non-doped AlGaAs layer with an Al composition of 8% to form the lower waveguide layer 03;

[0105] (3) Alternately grow 10nm GaAs barrier layer 04 (4 pieces) and 5.5nm GaNAsBi potential well layer 05 (3 pieces) with 1% compressive strain, in which the N component is about 2.28%, and the Bi component is about 3.25% , forming a 3-period multi-quantum well structure to form the active region 06 of the laser;

[0106] (4) grow a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com