A kind of preparation method of bismuth-containing semiconductor laser of 1300nm~1550nm

A laser and semiconductor technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of increasing the difficulty of the growth process, high non-radiative recombination rate, deterioration of laser performance, etc., to reduce the difficulty of the growth process, improve the injection efficiency, The effect of high characteristic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The preparation method of the 1300nm~1550nm bismuth-containing semiconductor laser is characterized in that the method comprises the following steps:

[0074] Step 1: The 1300nm-1550nm bismuth-containing semiconductor lasers are grown sequentially in the following order:

[0075] (1): growing an N-type AlGaAs transition layer on an N-type GaAs substrate;

[0076] (2): Growth of N-type AlGaAs or GaInP lower confinement layer;

[0077] (3): growing the AlGaAs lower waveguide layer;

[0078] (4): Growth of GaNAsBi / GaAs strained quantum well active region;

[0079] (5): growing the AlGaAs upper waveguide layer;

[0080] (6): growing a P-type AlGaAs electron blocking layer;

[0081] (7): growing a P-type AlGaAs upper confinement layer corresponding to the N-type AlGaAs lower confinement layer, or a P-type GaInP upper confinement layer corresponding to the N-type GaInP lower confinement layer;

[0082] (8): growing a P-type GaAs ohmic contact layer;

[0083] Step 2: The...

Embodiment 1

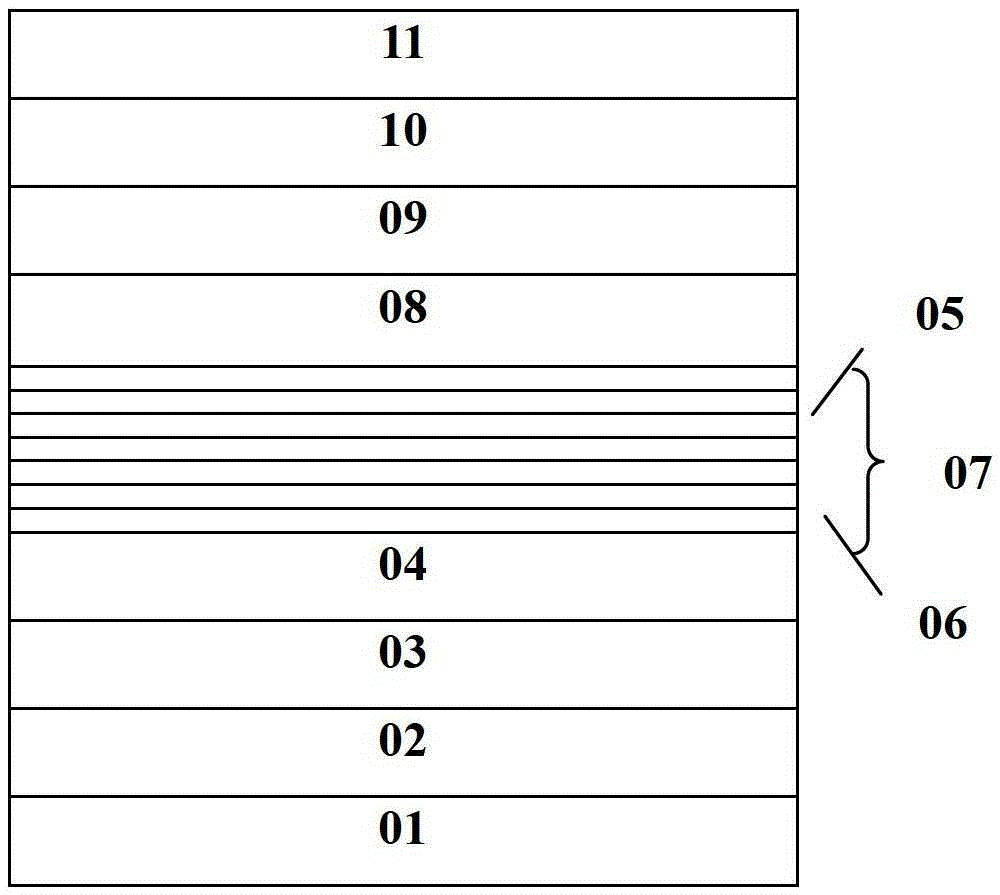

[0095] Embodiment one: if figure 1 , when using AlGaAs as the upper and lower confinement layers, the preparation method of the 1300nm~1.55μm bismuth-containing semiconductor laser comprises the following steps:

[0096] (1) grow the described 1300nm~1550nm bismuth-containing semiconductor laser with MOCVD method, its structure is as follows figure 1 Shown:

[0097] (1) N-type doping is grown on N-type GaAs substrate 01 with about 2×10 18 cm -3 The 0.05 micron AlGaAs layer, the Al composition is gradually changed from 0.1% to 10%, forming a transition layer 02;

[0098] (2) Grow N-type doped about 2×10 18 cm -3 A 0.2 micron AlGaAs layer with an Al composition of 15% forms the lower confinement layer 03;

[0099] (3) Grow a non-doped 0.1 micron AlGaAs composition gradient layer, and the Al composition is gradually changed from 15% to 0.1%, forming the lower waveguide layer 04;

[0100](4) Alternately grow 10nm GaAs barrier layer 05 (4 pieces) and 5.5nm GaNAsBi potential ...

Embodiment 2

[0107] Embodiment 2: as figure 1 , when using GaInP as the upper and lower confinement layers, the preparation method of the 1300nm~1.55μm bismuth-containing semiconductor laser comprises the following steps:

[0108] (1) Growth of 1300nm-1550nm bismuth-containing semiconductor lasers by MOCVD method, the structure of which is as follows figure 1 Shown:

[0109] (1) N-type doping is grown on N-type GaAs substrate 01 with about 2×10 18 cm -3 The 0.05 micron AlGaAs layer, the Al composition is gradually changed from 0.1% to 10%, forming a transition layer 02;

[0110] (2) Grow N-type doped about 2×10 18 cm -3 The 0.2 micron GaInP layer, the composition of Ga is 52%, forms the lower confinement layer 03;

[0111] (3) Grow a non-doped 0.1 micron AlGaAs composition gradient layer, and the Al composition is gradually changed from 15% to 0.1%, forming the lower waveguide layer 04;

[0112] (4) Alternately grow 10nm GaAs barrier layer 05 (4 pieces) and 5.5nm GaNAsBi potential w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com