A Vertical Cavity Surface Emitting Laser with Circular Spot

A vertical cavity surface emission, laser technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of device repeatability and uncontrollable yield, complex manufacturing process, large series resistance, etc., to improve the highest operation Power and reliability, large mode gain loss difference, and the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

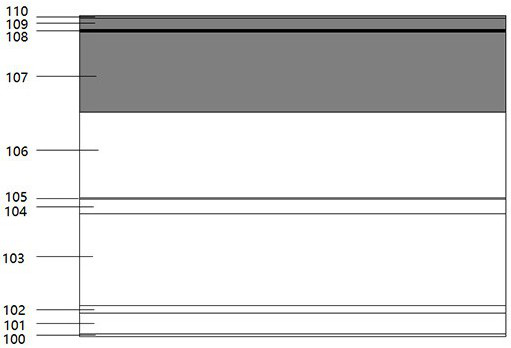

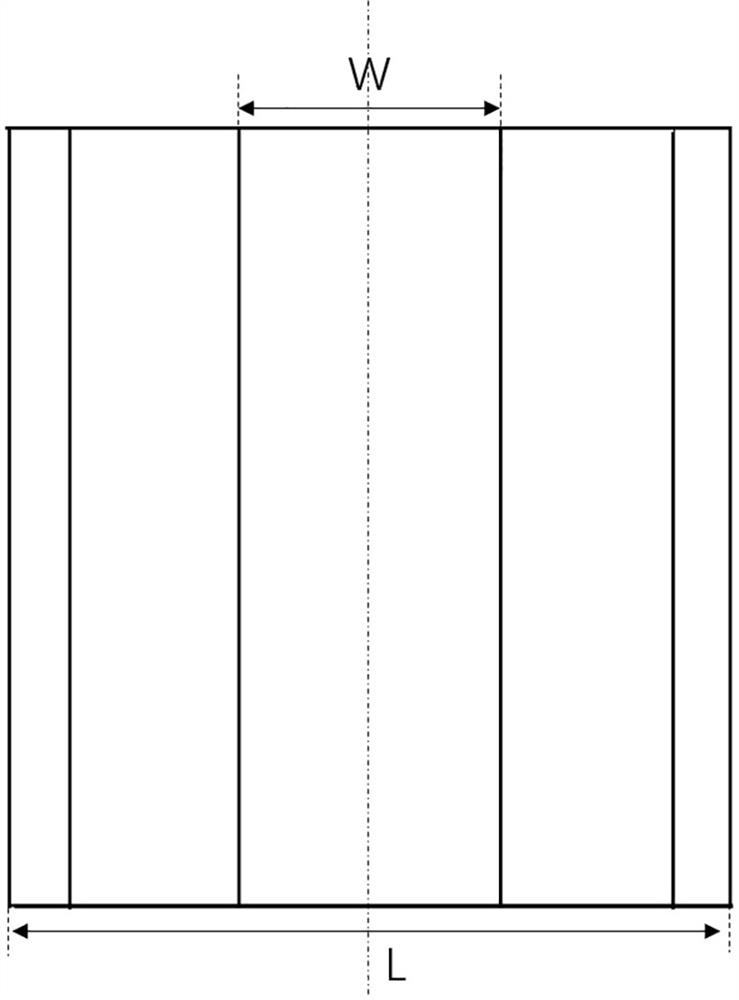

[0077] like figure 2 As shown, this embodiment provides a vertical cavity surface emitting laser with a circular spot, including a horizontal cavity laser unit, which includes an n-type contact metal layer 100, an n-GaAs Substrate 101, n-GaAs buffer layer 102, GaInP outer waveguide layer 103, first n-In x Ga 1-x As y P 1-y Lower waveguide layer 104, GaInP / In x Ga 1-x As y P 1-y / GaInP grating layer 105, second n-In x Ga 1-x As y P 1-y The lower waveguide layer 106, the third n-In x Ga 1- x As y P 1-y Lower waveguide layer 107, active layer 108, p-In x Ga 1-x As y P 1-y The upper waveguide layer 109 , the p-type contact layer 110 and the p-type contact metal layer 111 .

[0078] like figure 2 As shown, preferably, the thickness of the GaInP outer waveguide layer 103 is 3200 nm, which is used to confine the optical field.

[0079] like figure 2 Shown, preferably, GaInP / In x Ga 1-x As y P 1-y / GaInP grating layer 105 is GaInP layer, In x Ga 1-x As ...

Embodiment 2

[0097] like Figure 10 As shown, this embodiment discloses another vertical cavity surface emitting laser with a circular spot, which includes a horizontal cavity laser unit, and the horizontal cavity laser unit includes n-type contact metal layers 300, n -GaAs substrate 301, n-GaAs buffer layer 302, GaInP outer waveguide layer 303, n-In x Ga 1-x As y P 1-y Lower waveguide layer 304, active layer 305, first p-In x Ga 1-x As y P 1-y The upper waveguide layer 306, the second p-In x Ga 1-x As y P 1-y The upper waveguide layer 307, the third p-In x Ga 1-x As y P 1-y The upper waveguide layer 308 , the p-type contact layer 309 , and the p-type contact metal layer 310 .

[0098] like Figure 10 As shown, preferably, the layer thickness of the GaInP outer waveguide 303 is 2500 nm, which is used to confine the optical field.

[0099] like Figure 10 shown, preferably, n-In x Ga 1-x As y P 1-y The bandgap wavelength of the lower waveguide layer 304 is 870nm, the t...

Embodiment 3

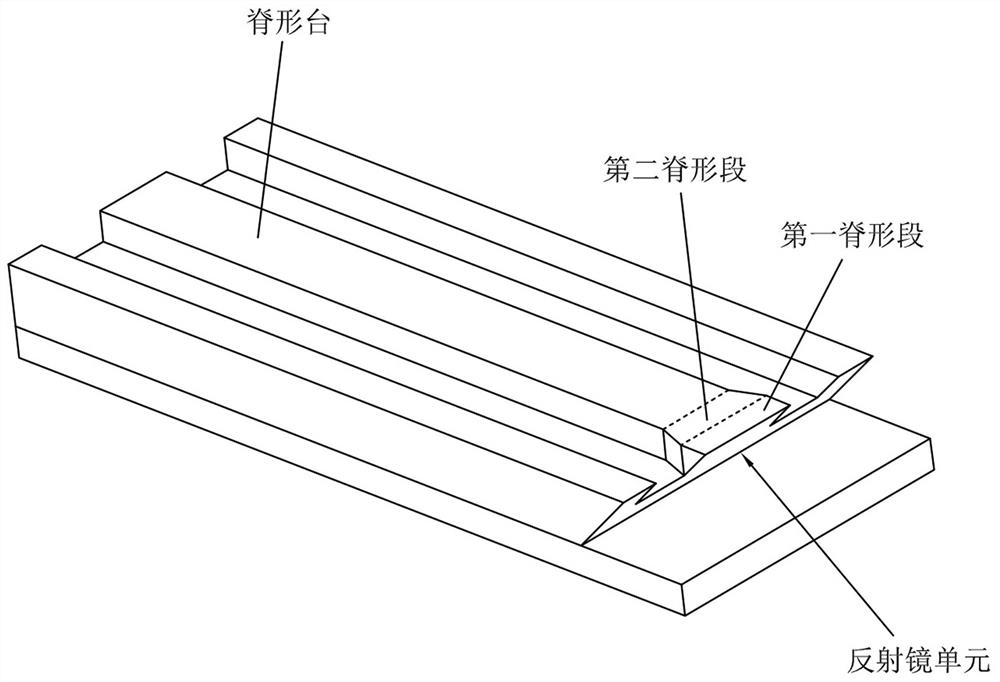

[0112] like Figure 14 As shown, the width of the second ridge section in this embodiment gradually increases from the upper ridge to the lower ridge, and the two side walls are curved. It can be seen from this that the plan view of the second ridge section is roughly arc-shaped. In addition, the technical features such as the specific structure of the horizontal resonator laser unit and the parameters of the rib region in this embodiment can be implemented by referring to the first or second embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com