Laser active region, semiconductor laser and manufacturing method thereof

A manufacturing method and laser technology, which are applied to semiconductor lasers, lasers, laser parts, etc., can solve the problems of easy introduction of defects, difficulties, and no refrigeration work when doped with N atoms, and achieve a large conduction band step ratio and electric field distribution. The effect of smoothing, improving slope efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings.

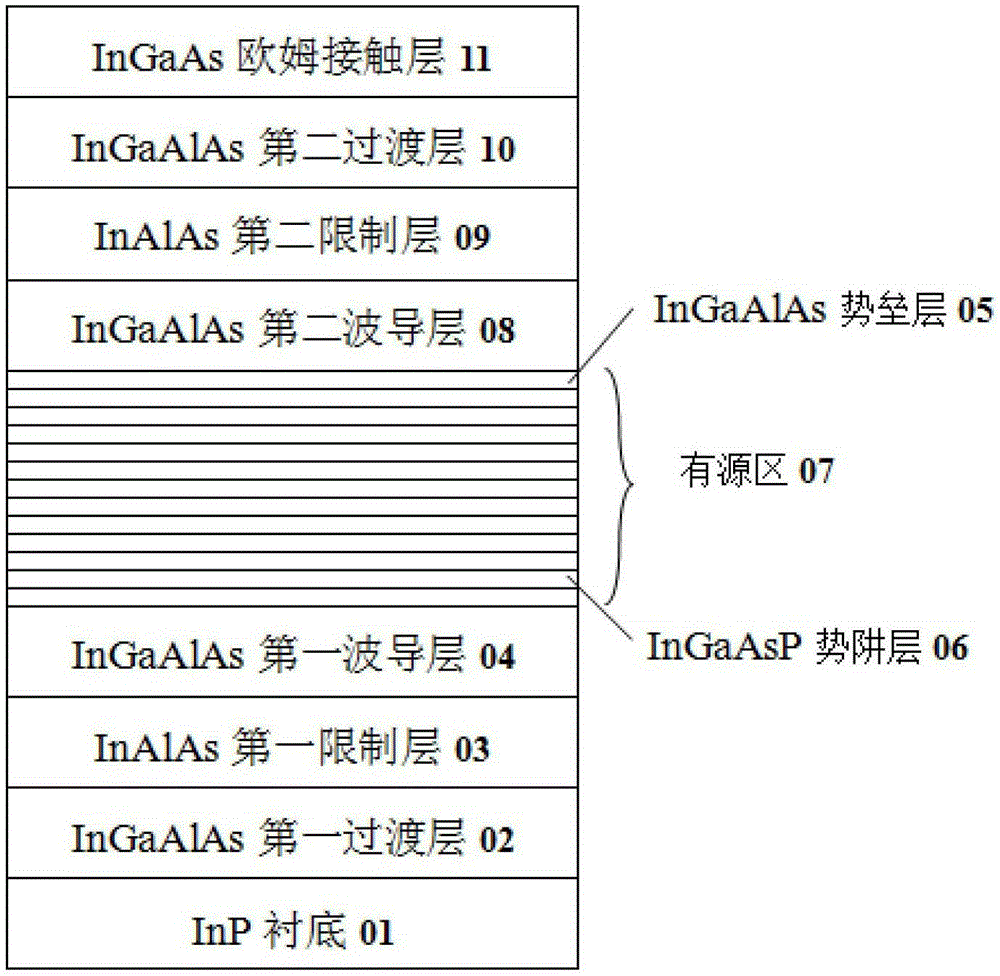

[0039] As mentioned above, in view of the deficiencies in the prior art, the present invention proposes a laser active region and a semiconductor laser including the active region, the semiconductor laser can achieve effective confinement of injected carriers and Uniform distribution of carriers in the active region, lower threshold current and higher differential gain, lower Auger recombination rate and cooling-free operation.

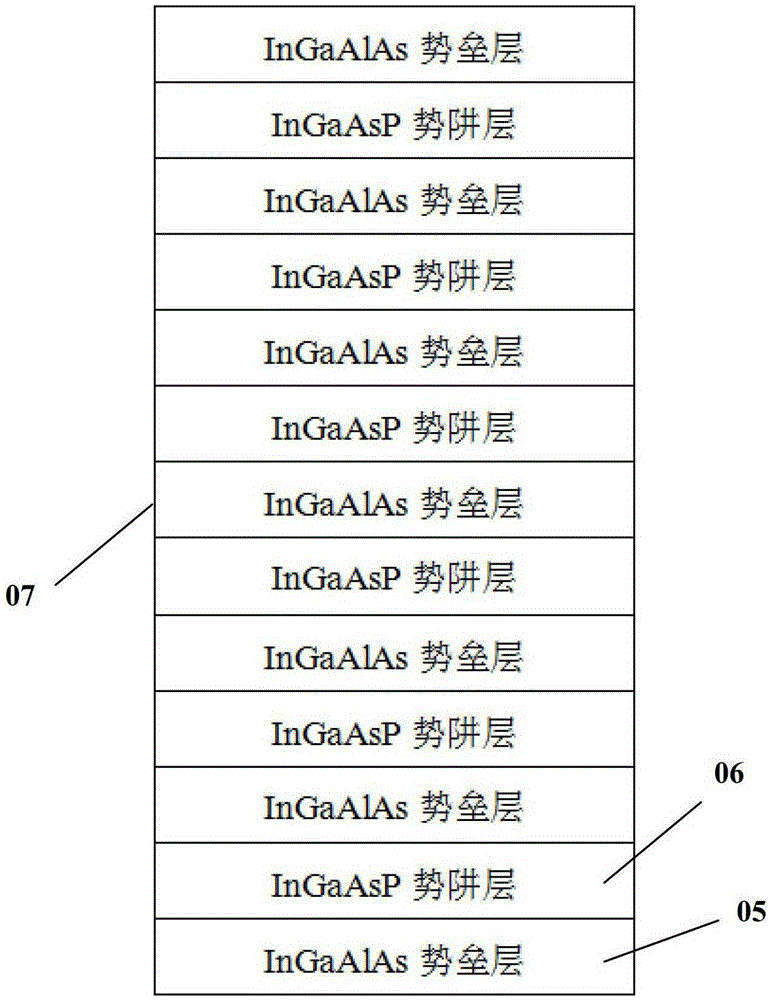

[0040] The laser active region includes a multi-quantum well structure, the material of the potential well layer in the multi-quantum well structure is InGaAsP, the material of the barrier layer in the quantum well structure is InGaAlAs, and the period number of the multi-quantum well structure is is K, the range of K is 3-20, the thickness of the potential well layer is 6-10 nm, and the thickness of the barrier layer is 10-20 nm.

[0041] Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com