Perovskite composite LED with multiple quantum wells and preparation method thereof

A multi-quantum well and perovskite technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., to achieve good lattice matching, less interface defects, and reduce non-radiative recombination centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

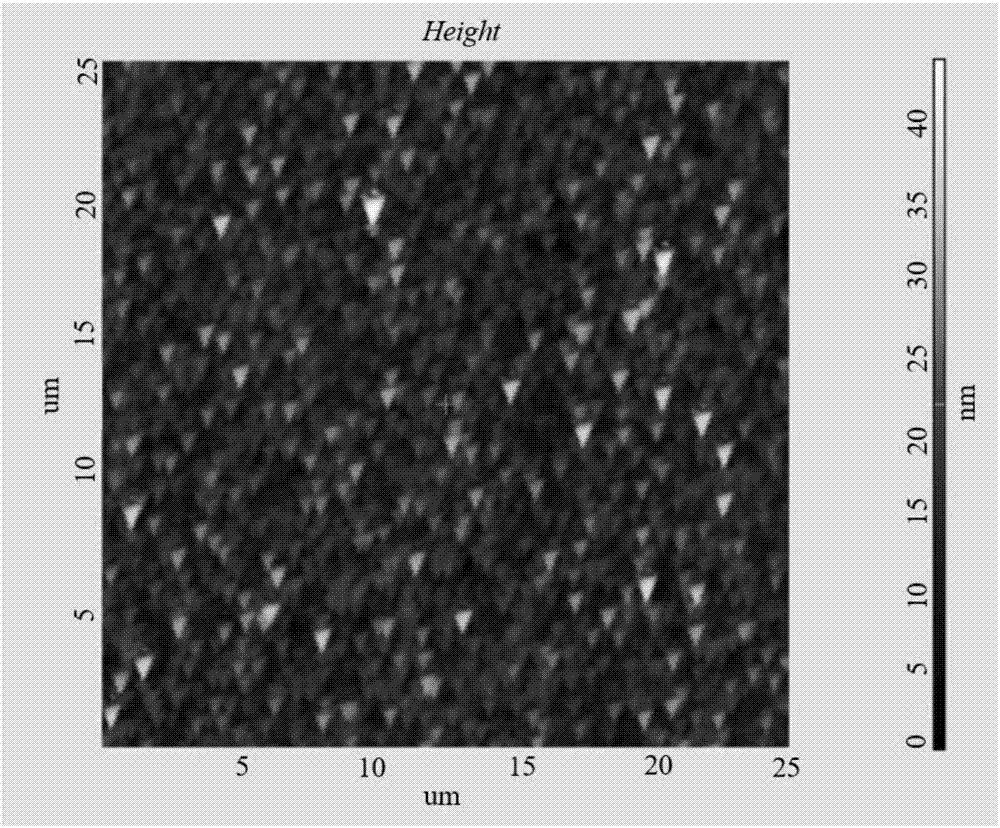

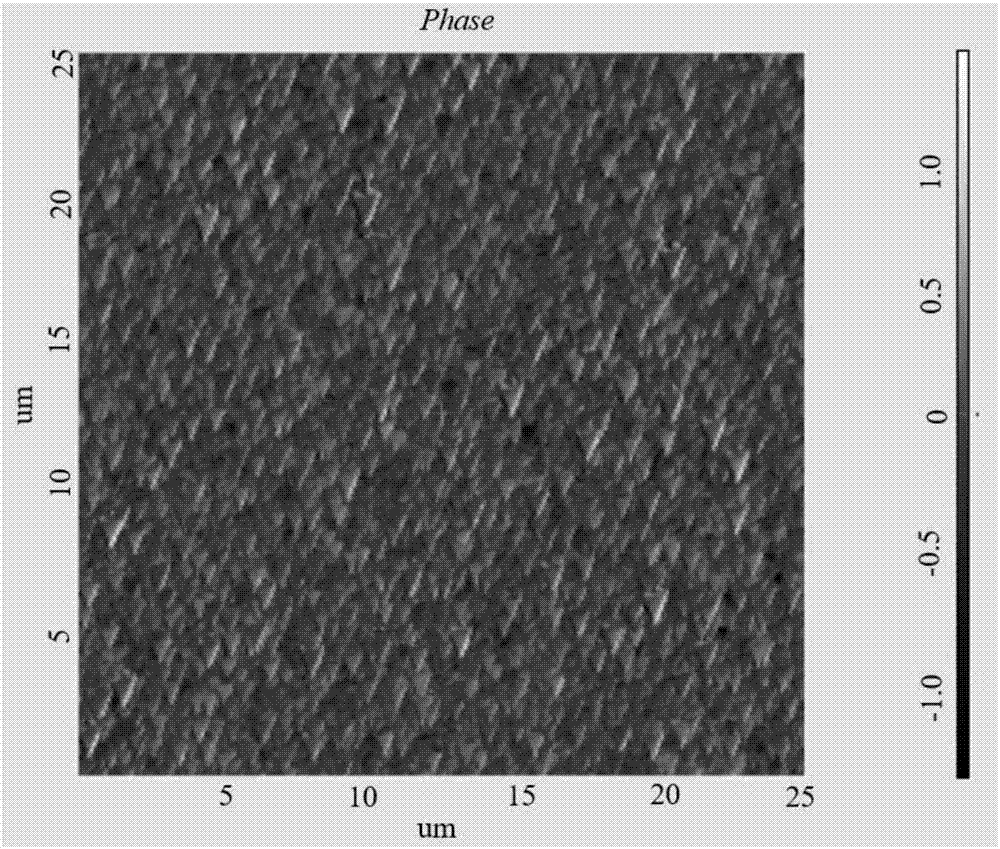

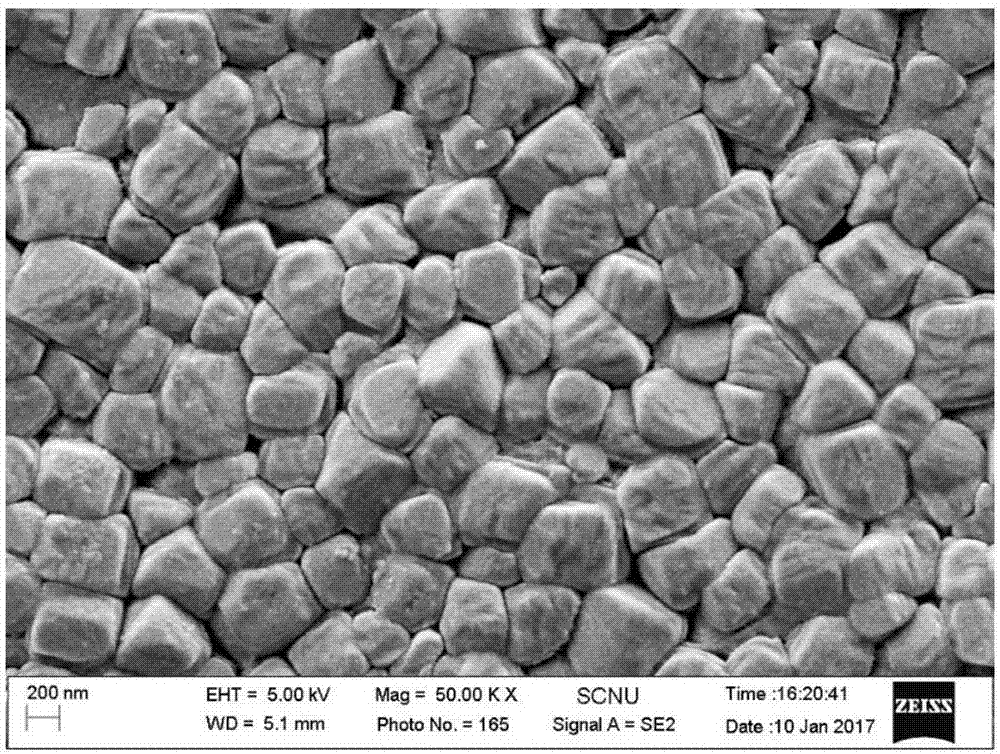

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a perovskite composite multi-quantum well LED described in the above technical solution, comprising the following steps:

[0037] (1) preparing an electron injection layer on the surface of the substrate;

[0038] (2) with CH 3 NH 3 PB 3 Quantum dots, PbBr 2 and CH 3 NH 3 Br is a raw material, and a light-emitting layer is prepared on the surface of the electron injection layer obtained in the step (1) by a low-temperature solution method;

[0039] (3) preparing a hole injection layer on the surface of the luminescent layer obtained in the step (2) by using a low-temperature solution method;

[0040] (4) Prepare electrodes on the surface of the hole injection layer obtained in the step (3) by thermal evaporation to obtain a perovskite composite multi-quantum well LED.

[0041] In the present invention, the substrate is preferably cleaned before preparing the electron injection layer. In the present inven...

Embodiment 1

[0075](1) Cleaning the transparent conductive substrate, the substrate used is etched FTO glass.

[0076] Using transparent and conductive FTO glass as the substrate, it is chemically cleaned. The cleaning steps are as follows: firstly, the substrate is ultrasonically cleaned with acetone and isopropanol solutions for 10 minutes, and recycled once; then, it is cleaned with deionized water ultrasonically. , and finally dried with high-purity nitrogen for later use. The thickness of the FTO thin film is 150 nm.

[0077] (2) Preparation of n-type TiO 2 Electron injection layer.

[0078] Put the cleaned FTO glass into Plasma, and treat it with ultraviolet oxygen for 10 minutes. Then transferred into the glove box (nitrogen atmosphere) to spin-coat TiO at 5000rpm 2 The precursor solution was immediately taken out of the glove box and heated in a tube furnace at 4505 °C for 40 minutes, and then naturally cooled to 120 °C, then put back into the glove box. (TiO 2 Precursor solu...

Embodiment 2

[0092] The difference between this example and Example 1 is that in the preparation of n-type TiO 2 In the electron injection layer:

[0093] Put the cleaned FTO glass into Plasma, and treat it with ultraviolet oxygen for 10 minutes. Then transferred into the glove box (nitrogen atmosphere) to spin-coat TiO at 5000rpm 2 The precursor solution was immediately taken out of the glove box and heated in a tube furnace at 500°C for 40 minutes, and then returned to the glove box when the temperature was naturally cooled to 120°C.

[0094] (TiO 2 Precursor solution formula: 369uL titanium tetraisopropoxide (TTIP) in 1 bottle was dissolved in 2.5mL isopropanol, 35uL 2mol / L concentrated hydrochloric acid in 2 bottles was dissolved in 2.5mL isopropanol, and then 2 The acid solution in the bottle was added dropwise to 1 bottle. )

[0095] In this implementation, for TiO 2 Precursor solution spin-coating speed increase, for TiO 2 Control of film thickness, the film thickness is redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com