Core-shell structured CuInS2/ZnS nanorod and preparation method thereof

A core-shell structure, cuins2 technology, applied in nanotechnology, nano-optics, nanotechnology and other directions, can solve the problems of inability to achieve mass production, inability to provide high quantum efficiency, quantum dots do not have nanorod optical properties, etc. Mass production, suppression of Auger non-radiative recombination, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

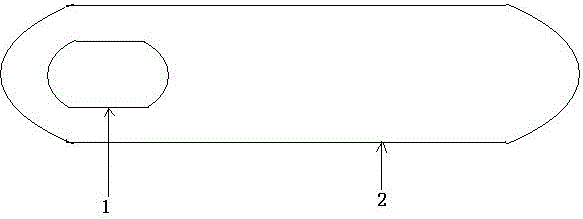

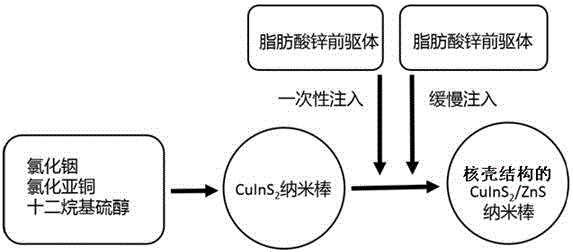

[0039] combine figure 2 As shown, CuInS with a core-shell structure with an aspect ratio of 20nm:5nm 2 / ZnS nanorods were prepared as follows:

[0040] (1) CuInS 2 Preparation of nanorods

[0041] Under an inert gas atmosphere, 0.45 mmol of indium chloride (InCl 3 ), 0.1 mmol of cuprous chloride (CuI) and 10 mmol of dodecanethiol (1-dodecanethiol), then heated the mixture under vacuum to 120 ° C and degassed for 30 mins, and then the degassed mixed The solution was heated to 230 °C for 300 s under an inert atmosphere to obtain CuInS 2 Nano stave;

[0042] (2) Preparation of fatty acid zinc precursor

[0043] Under an inert gas atmosphere, at 260 ° C, 0.2 mmol of zinc stearate, 0.5 mmol of dodecanethiol (1-dodecanethiol) and 8 mmol of 1-octadecene (1-Ocatadecene) were mixed and heated Obtain fatty acid zinc precursor.

[0044] (3) Growth of ZnS shell

[0045] Under an inert gas atmosphere, 3 / 4 of the fatty acid zinc precursor (containing 0.6 mmol fatty acid zinc) was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com