Method for deactivation of semiconductor laser cavity surface

A technology of lasers and semiconductors, applied in the direction of superimposed layer plating, ion implantation plating, coating, etc., can solve the problems of high cost, complicated process, and demanding equipment, and achieve stable performance, simple process, and low cost. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

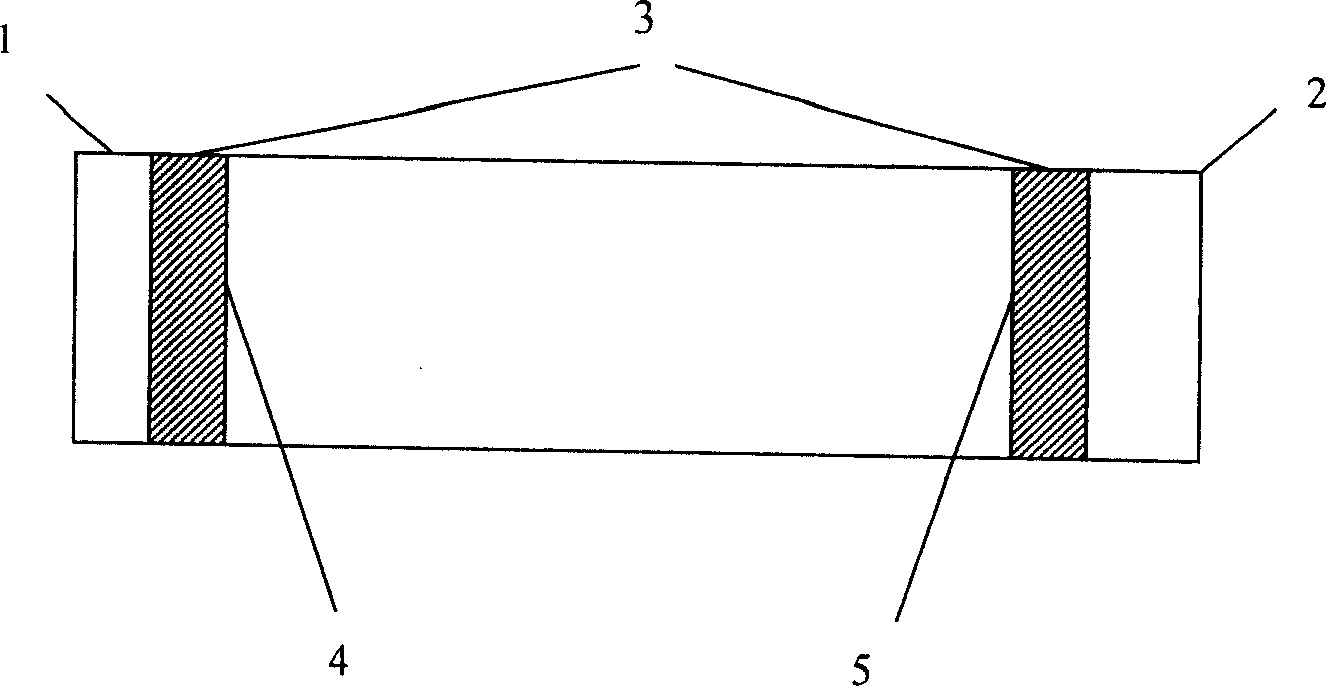

[0021] (1) After the semiconductor laser is cleaved into strips in the air, it is loaded into a special fixture for coating, and then placed in an electron beam evaporation vacuum chamber;

[0022] (2) Ion pre-cleaning: Ar or other ion sources with little damage can be selected; ion pre-cleaning is carried out on the front cavity surface 4 of the semiconductor laser for 30 seconds or 3 minutes or 6 minutes;

[0023] (3) Evaporating ZnSe or ZnS wide-bandgap low-absorption material on the front cavity surface 4 by electron beam evaporation as a passivation barrier layer 3 to prevent the diffusion of oxygen and impurities in the cavity surface mirror medium to the cavity surface;

[0024] (4) Anti-reflection coating 1 is plated on front chamber surface 4 according to prior art;

[0025] (5) After the fixture is turned over, the back cavity surface 5 is processed, and the above step (2) is carried out on the semiconductor laser back cavity surface 5;

[0026] (6) Evaporation of Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com