LED with two-dimensional photonic crystals

A two-dimensional photonic crystal and light-emitting diode technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low light-emitting efficiency of light-emitting diodes, increased non-radiative recombination, and damage to semiconductor active layers, and achieves high production costs. , Increase the brightness of the light output, improve the effect of the difference of the refraction law

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

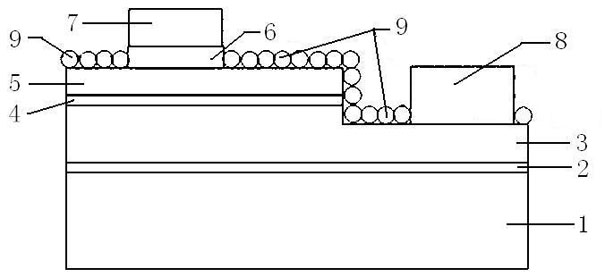

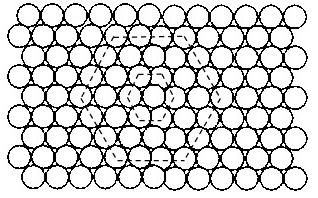

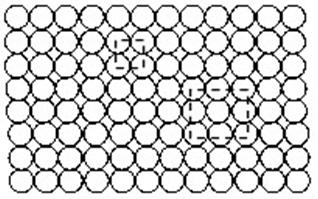

[0013] Specific Embodiment 1: This embodiment has a light-emitting diode with two-dimensional photonic crystals, including a substrate 1, a buffer layer 2, an N-type doped semiconductor layer 3, an active layer 4, a P-type doped semiconductor layer 5, and a current diffusion layer. 6. The P-type electrode 7 and the N-type electrode 8, the P-type electrode 7 is connected to the P-type doped semiconductor layer 5 through the current diffusion layer 6, and the N-type electrode 8 is directly connected to the N-type doped semiconductor layer 3, wherein The interface between the N-type doped semiconductor layer 3 and the air, and the interface between the P-type doped semiconductor layer 5 and the air are covered with a two-dimensional photonic crystal layer 9, and the two-dimensional photonic crystal layer 9 is a single-layer microsphere orderly arrangement structure , the particle size of the microspheres is 0.05 μm to 5 μm.

[0014] A schematic cross-sectional view of a light-emi...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment is different from Embodiment 1 in that the microspheres in the two-dimensional photonic crystal layer 9 are silicon dioxide microspheres, polystyrene microspheres or polymethyl methacrylate microspheres. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the microspheres in the two-dimensional photonic crystal layer 9 are silicon dioxide microspheres, polystyrene microspheres or polymethylmethacrylate coated with metal on the outer layer. Ester microspheres where the metal is Ag, Pt, Au, Cu or Al. Other parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com