N-type back junction crystalline silicon cell and preparation method thereof

A crystalline silicon battery, N-type technology, applied in the direction of circuits, electrical components, photovoltaic power generation, etc., can solve the problems of increased battery body recombination, reduced production costs, reduced surface doping concentration, etc., to reduce mask deposition and mask Etching process, reducing the cost of production process, and reducing the effect of interfacial recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

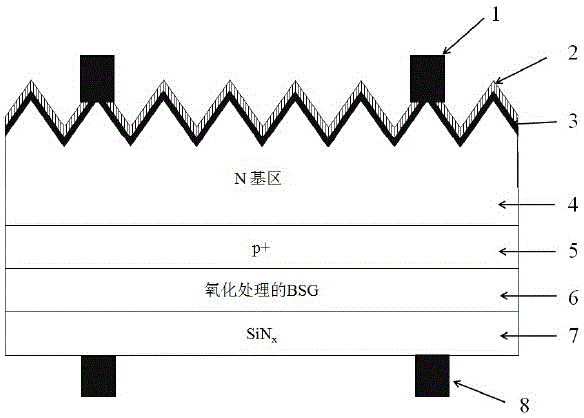

[0028] A method for preparing a rear junction N-type crystalline silicon solar cell, comprising the steps of:

[0029] (1) Use N-type single crystal silicon wafer as the substrate, the resistivity is 1~12W·cm, and the thickness is 170~200mm. The silicon wafer is cleaned to remove the damaged layer on the surface, and the silicon The sheet is polished, and the mass fraction of sodium hydroxide is 20%;

[0030] (2) Place the front side of the above-mentioned silicon chip face-to-face for single-sided boron diffusion. The back side of the silicon chip is a boron diffused emitter P+ layer with a sheet resistance of 60Ω / □, using BBr 3 Liquid source diffusion, the diffusion temperature is 950 degrees, and the time is 60 minutes;

[0031] (3) During the cooling process after the boron diffusion propulsion is completed, a certain flow rate of oxygen is introduced to oxidize the borosilicate glass and its interface with silicon until the temperature is lowered to 790°C, the flow rate ...

Embodiment 2

[0040] A method for preparing a rear junction N-type crystalline silicon solar cell, comprising the steps of:

[0041] (1) Use N-type single crystal silicon wafer as the substrate, the resistivity is 1~12W·cm, and the thickness is 170~200mm. The sheet is polished, and the mass concentration of potassium hydroxide is 25%;

[0042] (2) Place the front side of the above-mentioned silicon chip on the surface for single-sided boron diffusion. 3 Liquid source diffusion, the diffusion temperature is 970 degrees, and the time is 60 minutes;

[0043] (3) During the cooling process after the boron diffusion propulsion is completed, a certain flow of oxygen is introduced to oxidize the borosilicate glass and its interface with silicon until the temperature is lowered to 760°C, the flow rate of oxygen is 5slm, and the oxidation time is 40min.

[0044] (4) Deposit a layer of silicon nitride film on the oxidized borosilicate glass layer by plasma enhanced chemical vapor deposition (PECVD)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com