Infrared semiconductor laser active region, semiconductor laser and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems that III-V semiconductor materials cannot be used in the wavelength range, and laser diodes have not been successfully developed, so as to reduce the interfacial recombination rate, Effects of improving performance and life, and reducing optical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment takes a single quantum well laser with a wavelength of 4 μm as an application example to further illustrate the technical solution of the present invention, but this should not limit the protection scope of the present invention.

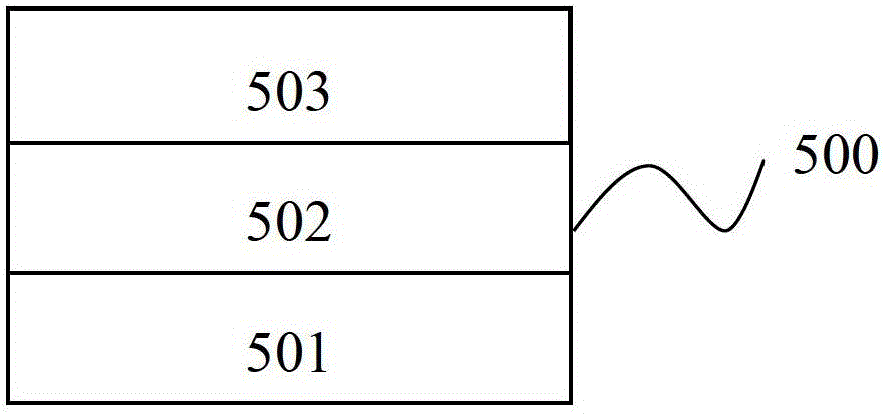

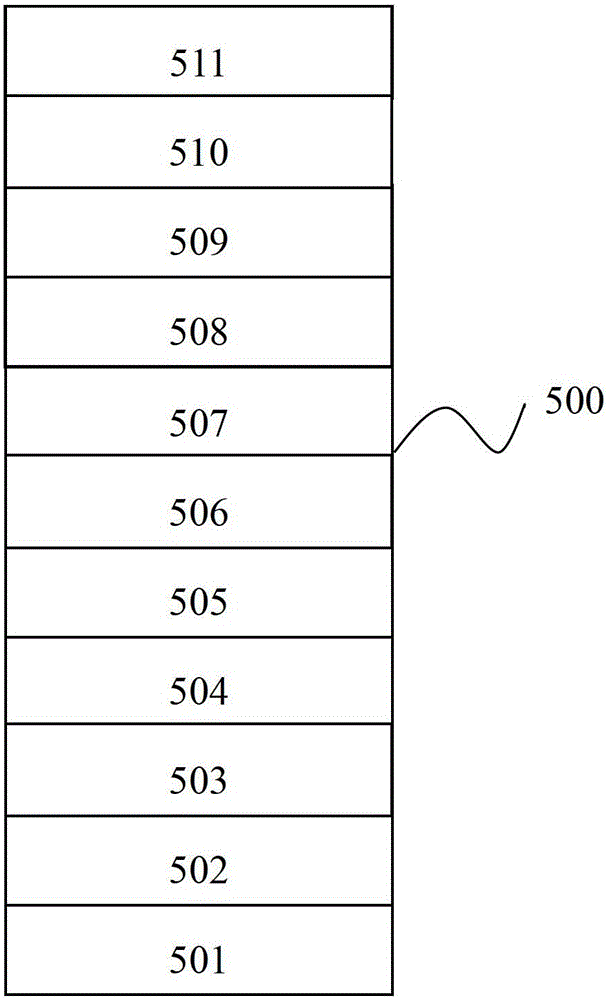

[0037] like figure 1 As shown, the active region 500 of the infrared semiconductor laser is a single quantum well structure, and the material of the potential well layer 502 is In m Ga 1-m As 1-n Bi n , wherein the composition m of In is 0.008, and the composition n of Bi is 0.028; the material of barrier layers 501, 503 is In x Ga 1-x As 1-y Bi y , where the values of the components x and y of In and Bi gradually change from 0.48 to 0.54 and 0.04 to 0 respectively in the direction away from the potential well layer.

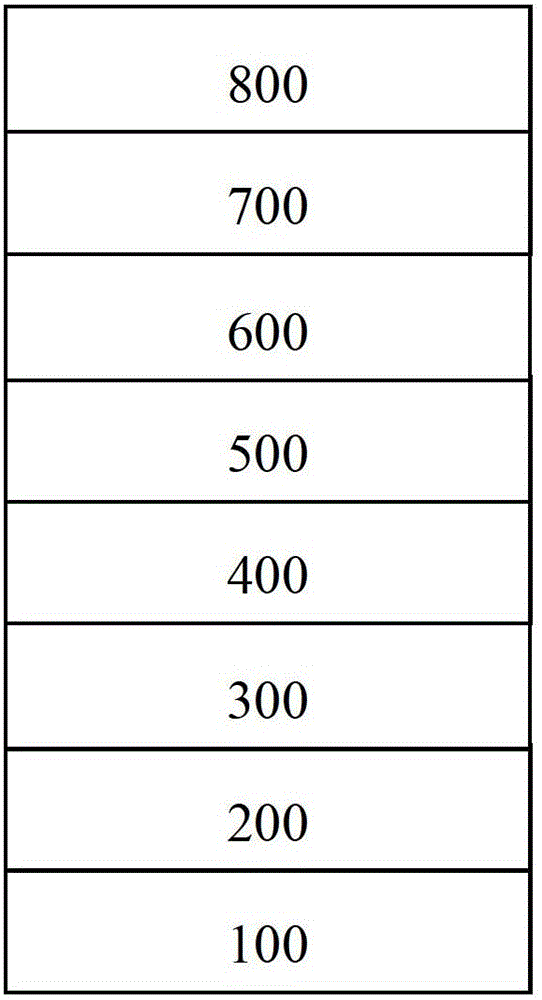

[0038] In this embodiment, a waveguide layer (attached figure 1 Not shown in ), the material of the waveguide layer is In x Ga 1-x As 1-y P y ; The waveguide layer is a graded waveguide layer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com