Multilayer cascaded photocathode with wide spectral response and preparation method thereof

A photocathode, wide-spectrum technology, applied in the manufacturing of light-emitting cathodes, photo-emission cathodes, main electrodes of discharge tubes, etc., can solve the problems of no photoelectric response, short wavelength limit of materials, etc., to achieve favorable migration and emission, wide-spectrum response , the effect of increasing the diffusion length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing a multi-layer cascaded wide-spectrum response photocathode, the specific steps are:

[0033] Step 1. On the substrate, sequentially grow the InGaAs buffer layer, p-type Al 0.8 In 0.2 As corrosion barrier layer, p-type emitter layer In x Ga 1-x As part, p-type emission layer GaAs part, p-type emission layer Ga 1-y al y As part and protective layer;

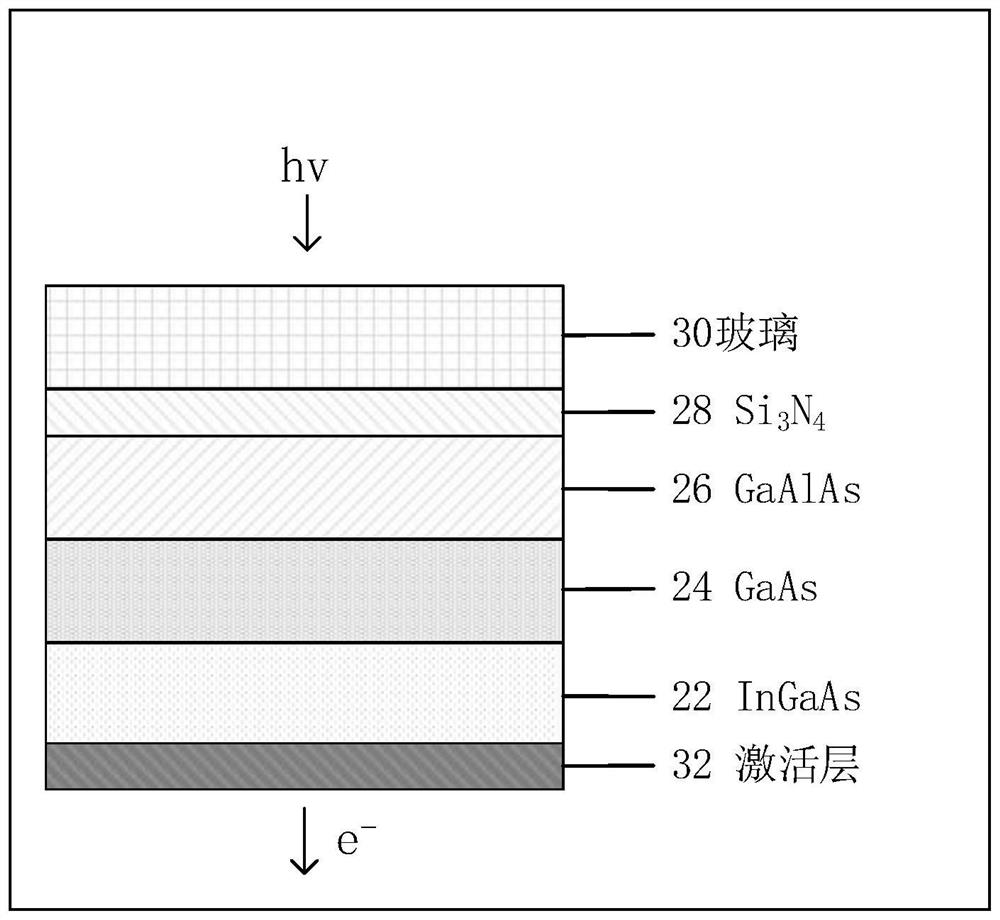

[0034] Step 2, corrode the protection layer with a chemical etchant, the Ga in the emitter layer 0.1 al 0.9 A layer of Si is deposited on the upper surface of the As layer 3 N 4 antireflective coating, then the Si 3 N 4 Thermally bonded countertop glazing on anti-reflective film;

[0035] Step 3, sequentially corrode the substrate, In x Ga 1-x As buffer layer, p-type Al 0.8 In 0.2 As corrosion barrier layer, exposed In in the emitter layer x Ga 1-x As surface;

[0036] Step 4, through the ultra-high vacuum activation process, on the surface of the e...

Embodiment

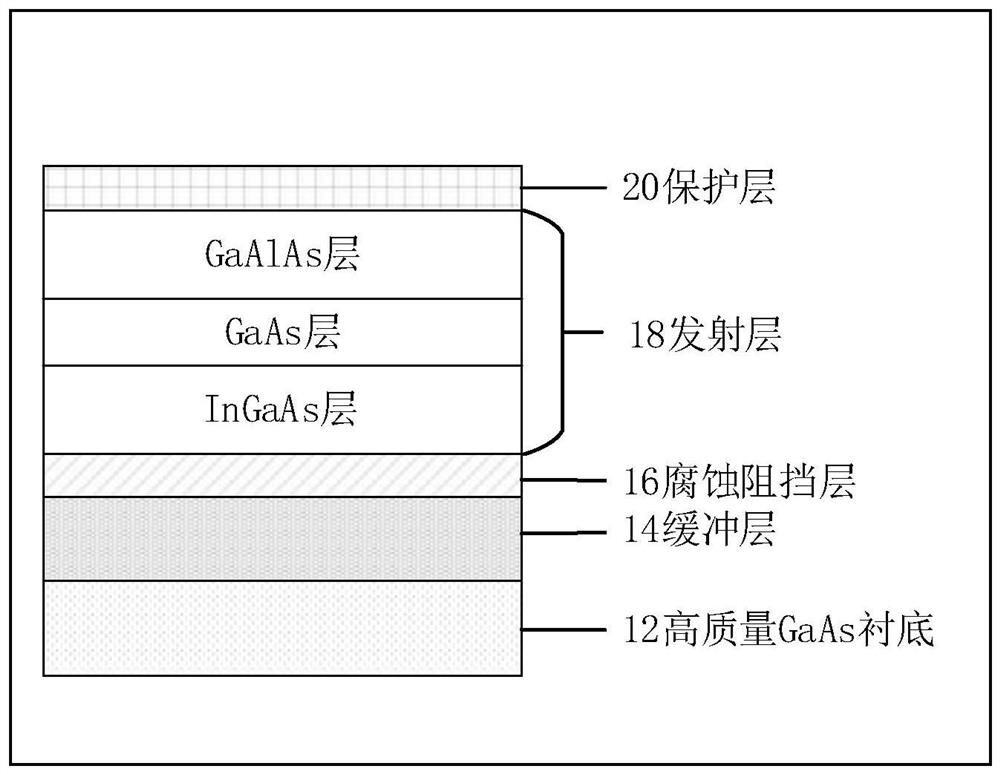

[0039] A multilayer cascaded photocathode with wide spectral response, including a bottom-up substrate, an InGaAs buffer layer, a p-type Al 0.8 In 0.2 As corrosion barrier layer, p-type emission layer and protective layer, wherein, the p-type emission layer comprises p-type In x Ga 1-x As layer, p-type GaAs layer, p-type Ga 1-y al y As layer.

[0040] In x Ga 1-x The In composition of the As buffer layer increases from bottom to top layer by layer from 0 to 0.2, wherein the thickness of each layer is 1 μm, and the total thickness of the buffer layer is 4 μm.

[0041] p-type Al 0.8 In 0.2 The In composition in As is 0.2, and the doping concentration is 3×10 17 cm -3 . The total thickness of the corrosion barrier layer is 1 μm.

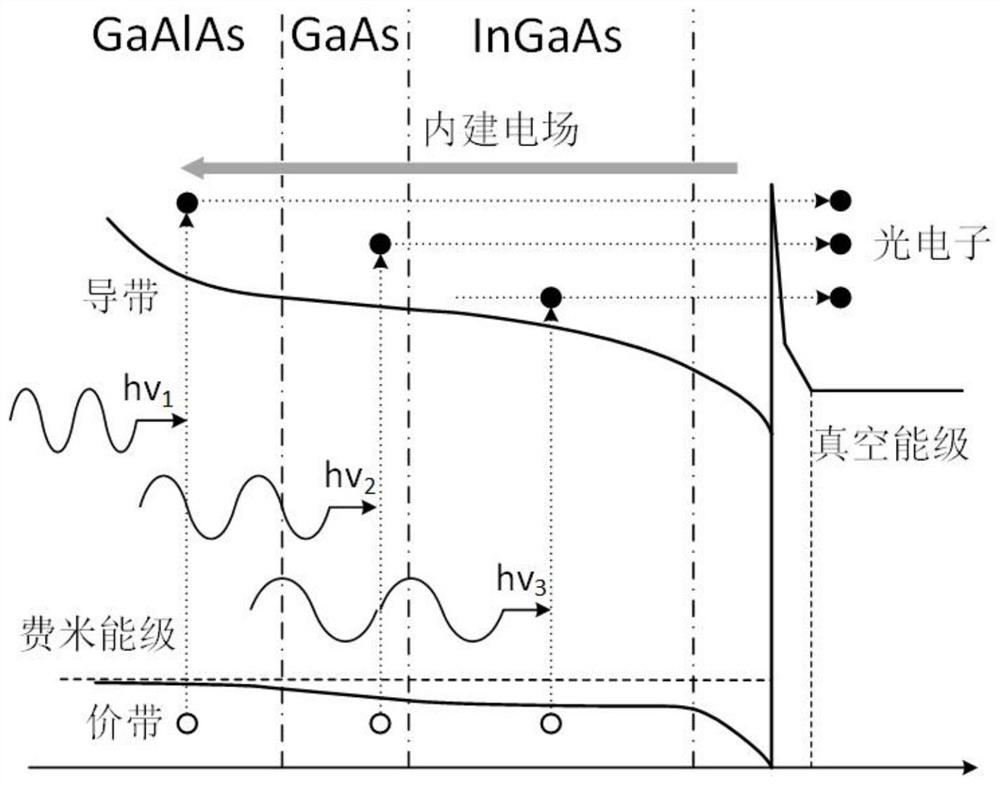

[0042] Such as image 3 As shown, the emission layer is divided into three sub-layers, namely In x Ga 1-x As layer, GaAs layer, Ga 1-y al y As layer. where In x Ga 1-x The As layer is divided into four layers with different In compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com