Variable-component variable-doping reflective Al<x>Ga<1-x>As/GaAs photocathode and preparation method thereof

A photocathode and variable doping technology, which is used in the manufacture of light-emitting cathodes, image conversion/image amplifier tubes, cathode ray tubes/electron beam tubes, etc. Efficiency, the effect of improving transport capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

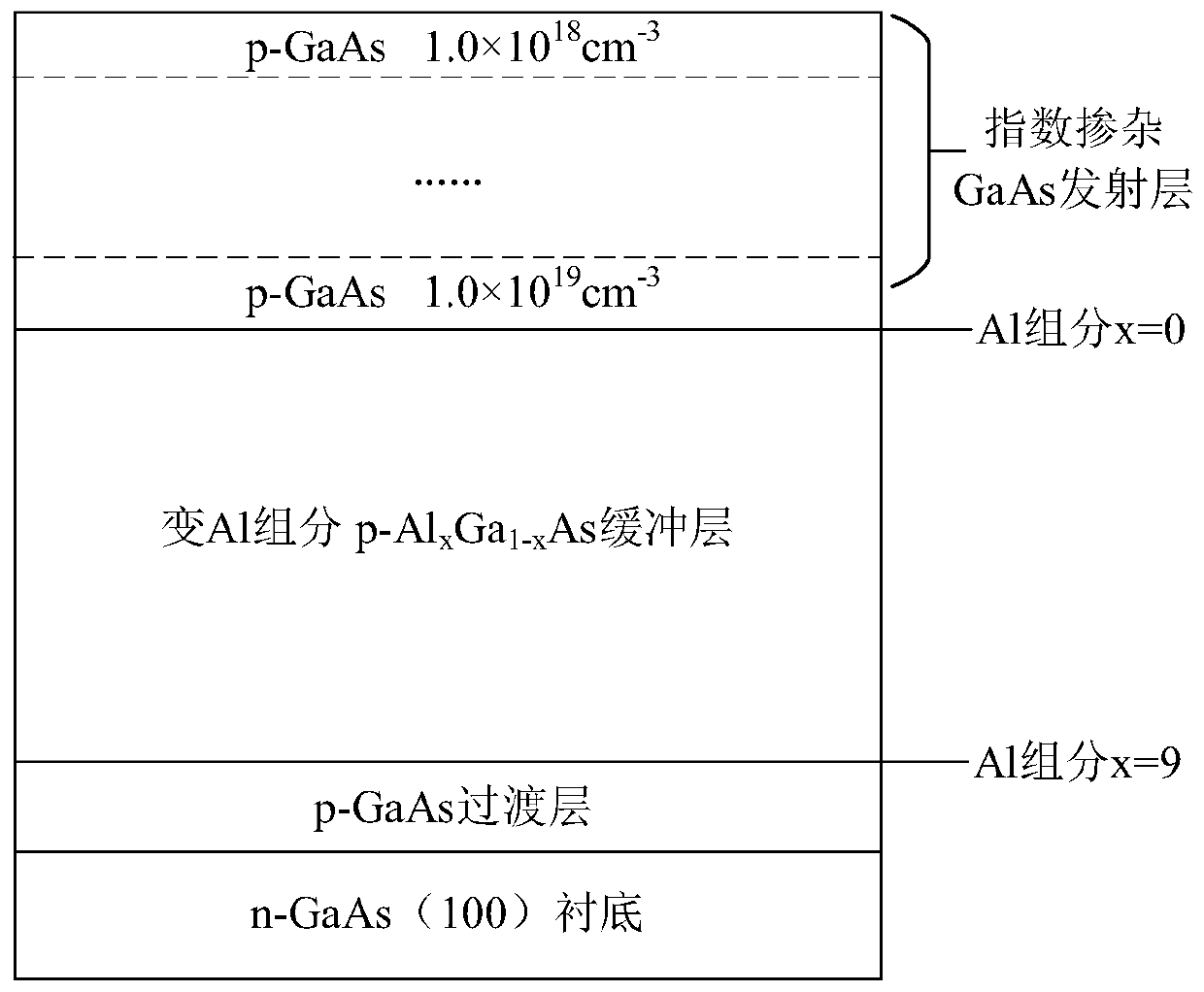

[0035] A variable composition variable doping reflective Al x Ga 1-x The preparation method of As / GaAs photocathode comprises the following steps:

[0036] Step 1: growing a GaAs transition layer on the GaAs substrate.

[0037] Step 2: Then grow Al composition Al on the GaAs transition layer x Ga 1-x As buffer layer.

[0038] Step 3: Change Al composition Al x Ga 1-x The As buffer layer is sequentially grown into individual unit layers of the exponentially doped GaAs emitter layer.

[0039] Step 4: Chemically clean the surface of the variable-composition variable-doped GaAs photocathode generated in step 3, and then send it to an ultra-high vacuum system for high-temperature heating, so that the surface of the GaAs photocathode is clean at the atomic level.

[0040] Step 5: Through the ultra-high vacuum activation process, the Cs and O 2 The alternating adsorption of Cs / O active layer is formed, and the high quantum efficiency variable composition variable doping refle...

specific Embodiment

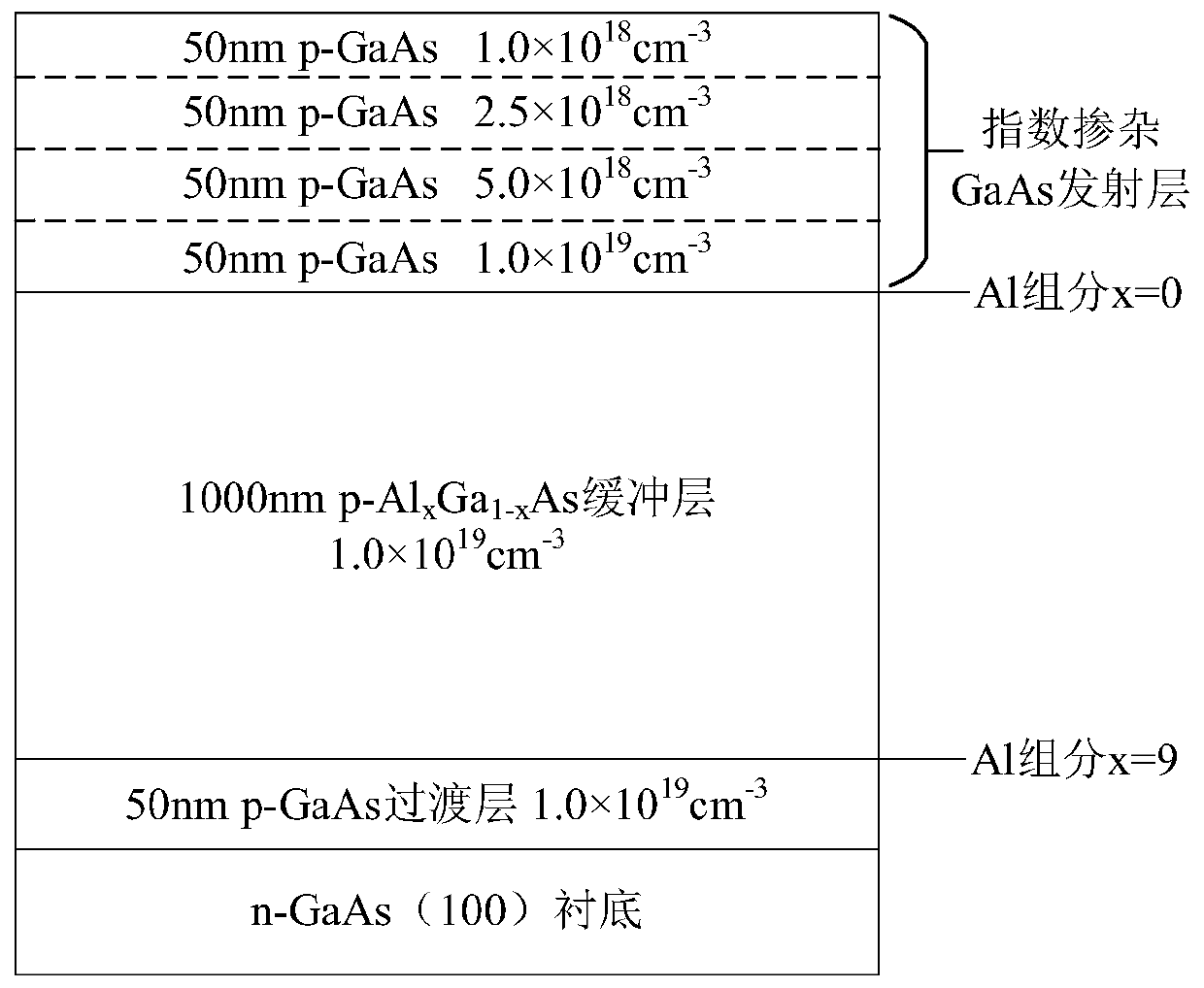

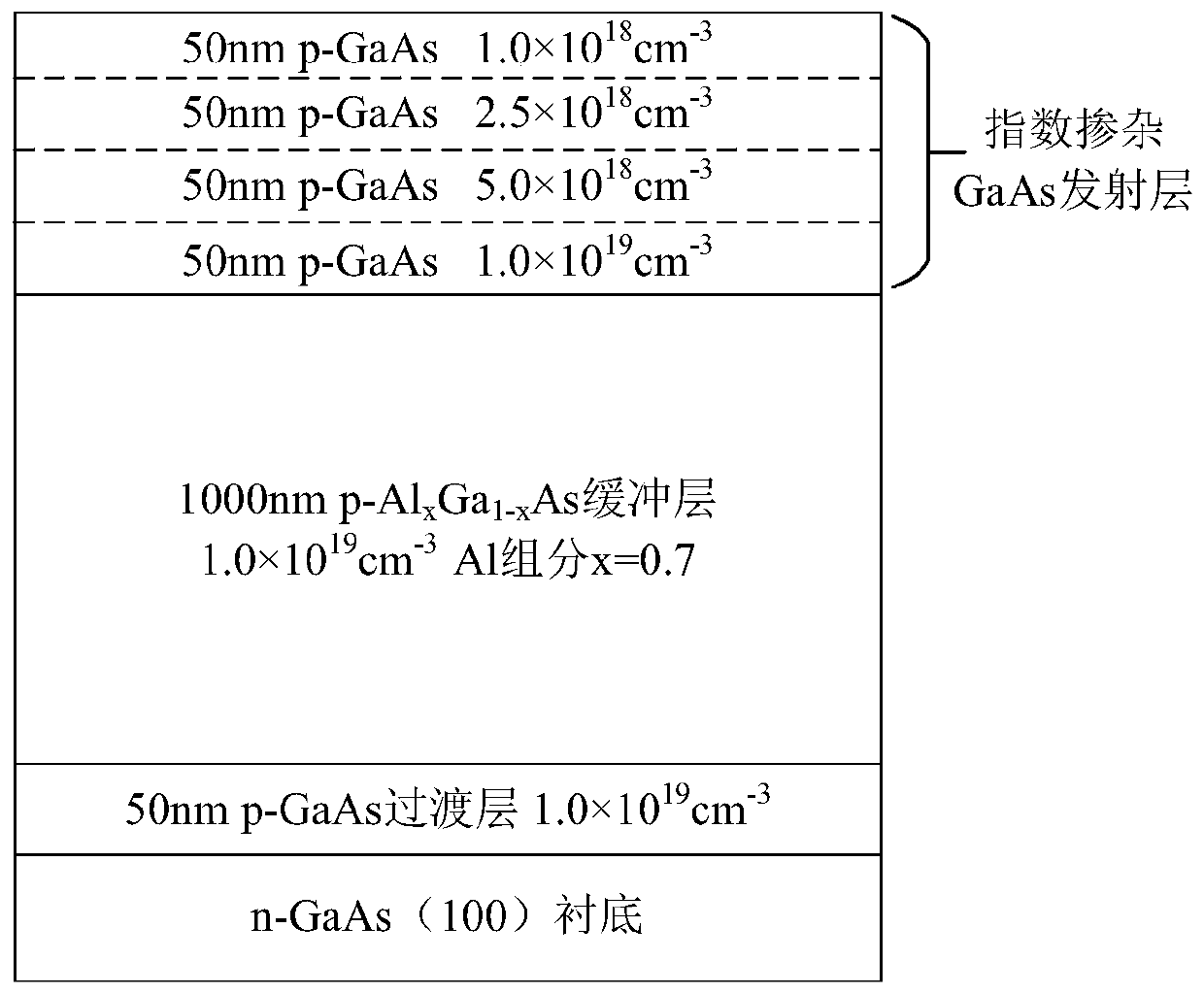

[0044] Such as figure 2 As shown, the variable composition variable doping reflective Al made by the method of the present invention x Ga 1-x Schematic diagram of the As / GaAs photocathode structure. The cathode consists of a p-type GaAs transition layer with a thickness of 50nm from bottom to top, and a doping concentration of 1.0×10 19 cm -3 ; Thickness of 1000nm p-type variable Al component Al x Ga 1-x As buffer layer, the doping concentration is 1.0×10 19 cm -3 , the Al composition gradually changes from 0.9 to 0 from the rear interface to the emission layer interface; and the p-type index-doped GaAs emission layer with a total thickness of 200nm, the emission layer is a layered structure of 4 units, and the thickness of each unit is 50nm, the doping concentration from the rear interface to the emission surface is 1.0×10 19 cm -3 , 5.0×10 18 cm -3 , 2.5×10 18 cm -3 , 1.0×10 18 cm -3 .

[0045] The variable composition variable doping reflective Al x Ga 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com