Method for cleaning passivated GaAs wafer surface

A wafer, ozone technology, applied in electrical components, semiconductor/solid state device manufacturing, circuits, etc., can solve problems such as environmental hazards and GaAS surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

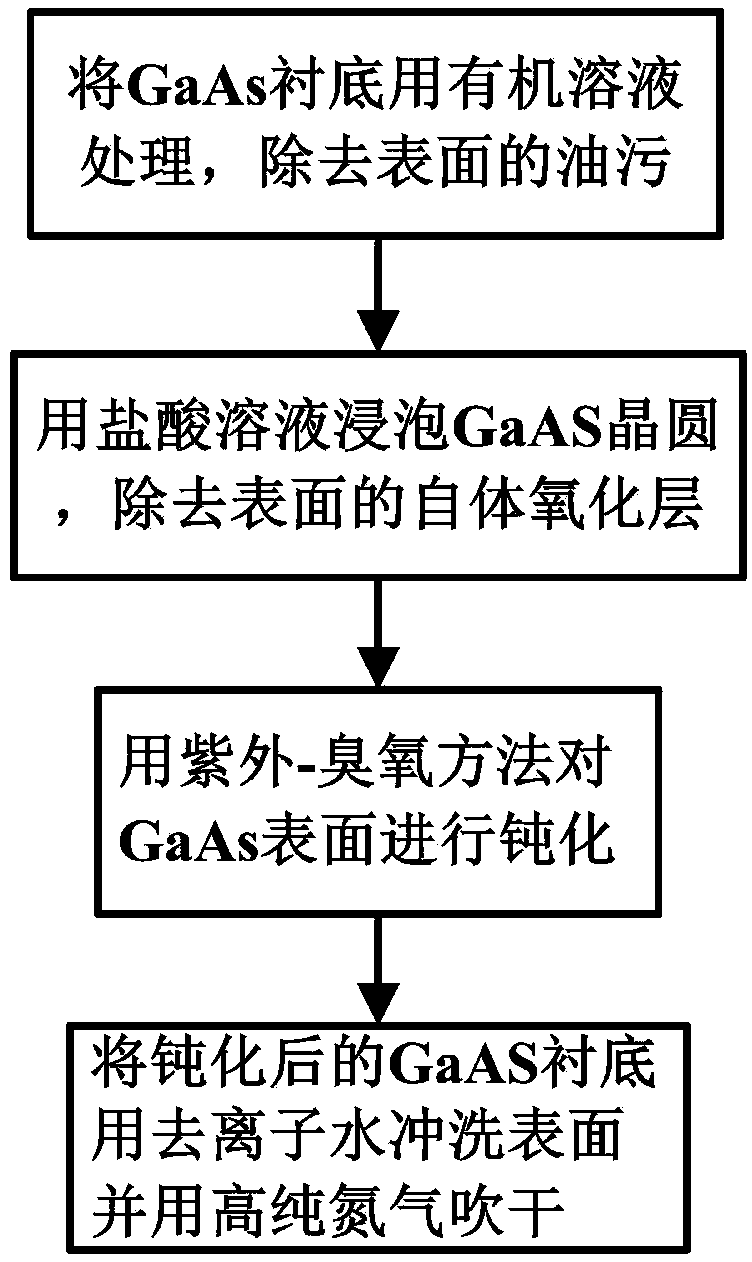

Method used

Image

Examples

Embodiment

[0019] According to the method, HCl is used to remove the autogenous oxide layer on the surface of the wafer and the UV-ozone method is used for passivation.

[0020] Table 1 is the comprehensive XPS spectrum data of the wafer treated by this method, from which it can be seen that the chemical dose ratio of the surface after treatment is also close to that of the bulk, that is, this method will not affect the surface characteristics of the wafer while completing the passivation.

[0021] 2. The low-noise device and power device were prepared by four ion-implanted materials with different passivation, and the noise and power performance were measured at 4GHz and 12GHz, and the antistatic ability was tested.

[0022] Table 2 shows the comparison results of power and antistatic ability between this method and the other two methods. Among them, Table 2(a) is the test result of the die working at 4GHz, and Table 2(b) is the test result of the die It is the result of testing under 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com