Method for manufacturing soft elastic abrasive, cutting tool and treatment method for mold

A manufacturing method and cutting tool technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of short cutting distance, high spray pressure, etc., and achieve the effects of increased spray distance, reduced loss, good removal ability and polishing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

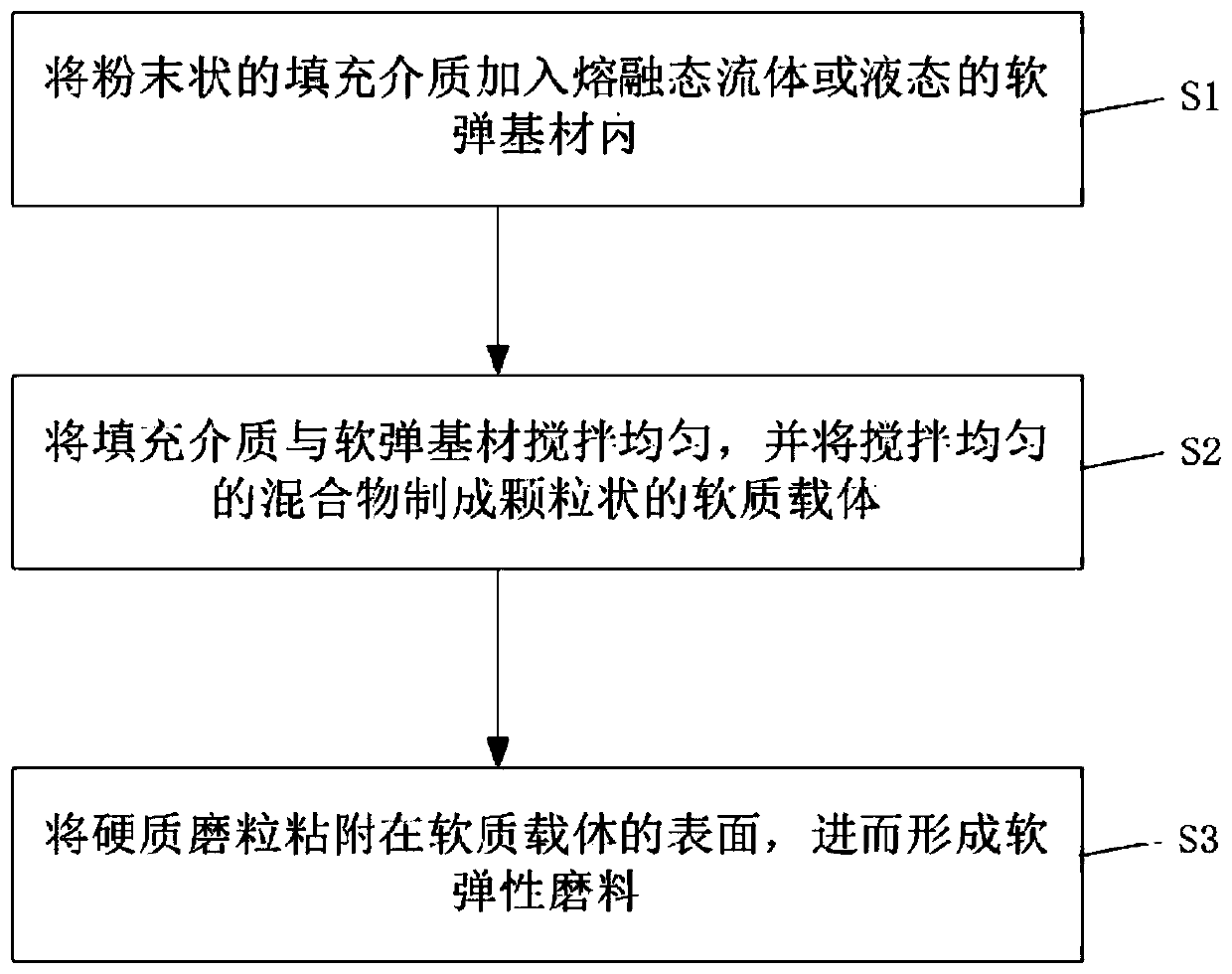

[0062] See attached figure 1 to attach image 3 , The invention discloses a method for manufacturing a soft elastic abrasive, comprising the following steps.

[0063] S1. Add the powder filling medium into the molten fluid or liquid soft elastic base material, the volume ratio of the filling medium to the soft elastic base material is less than or equal to 3:10.

[0064] Wherein, the Shore hardness of the soft elastic substrate is less than or equal to 60HA, and the density is 0.6-1.6g / cm 3 , The permanent deformation rate is less than 30%. In addition, the soft elastic base material is preferably a material with the properties of natural recovery deformation within 3 minutes and elongation at break between 100% and 2000%, and the soft elastic base material with this property has good elasticity, which is convenient It is the elastic deformation of the abrasive body.

[0065] The soft elastic base material can use polymer synthetic material or natural material satisfying t...

Embodiment 1

[0096] The preparation method of soft elastic abrasive is as follows:

[0097] A1: Add copper powder into molten fluid or liquid isoprene rubber, where the volume ratio of copper powder to isoprene rubber is 13:87.

[0098] Among them, the density of copper powder is 8.9g / cm 3 , the particle size is 0.5μm; the density of isoprene rubber is 0.94g / cm 3 , the hardness is Shore A 40, and the permanent deformation rate is 10%.

[0099] B1: Stir the copper powder and isoprene rubber evenly, and make the uniformly stirred mixture into a soft carrier with a particle size of 0.6mm, and the density of the prepared soft carrier is 2.5g / cm 3 .

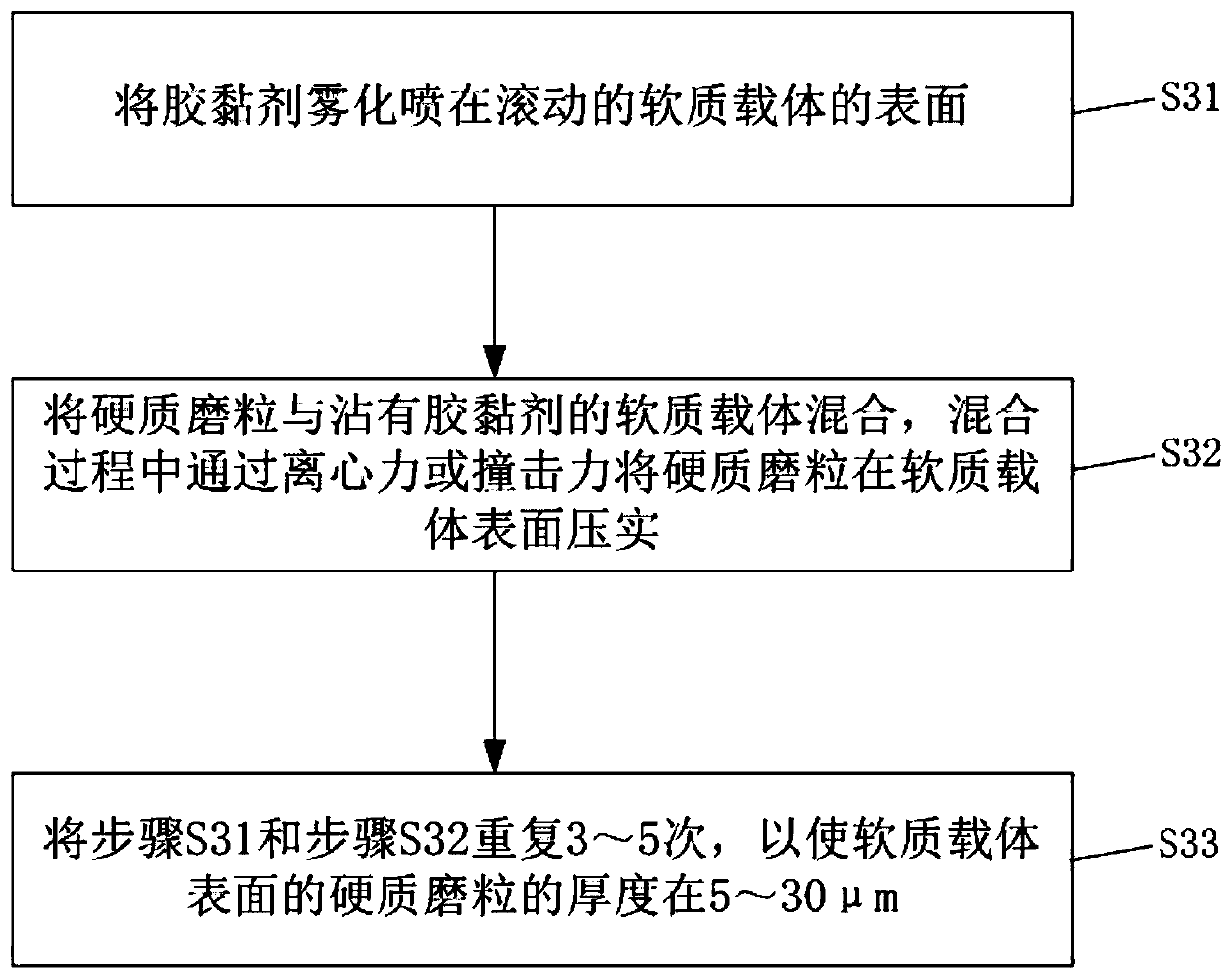

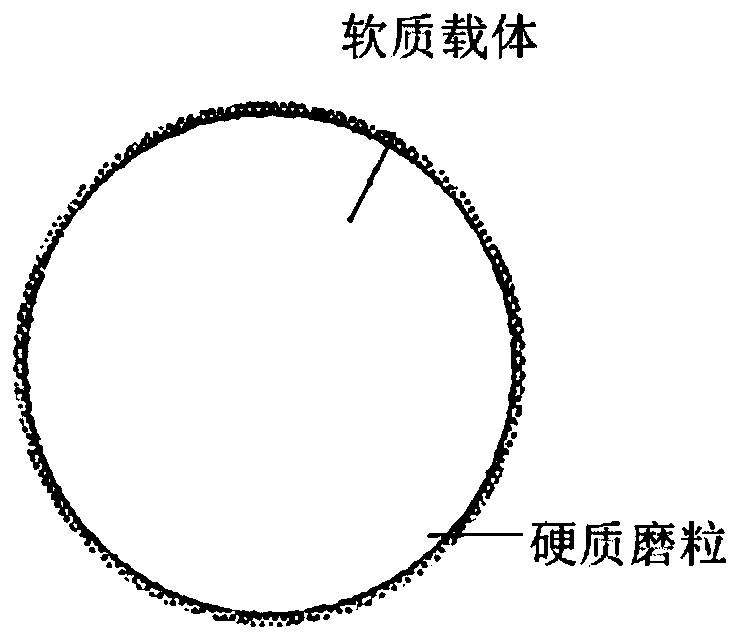

[0100] C1: Hard abrasive grains are adhered to the surface of the soft carrier to form soft elastic abrasives. The composition of the hard abrasive grains is 70% diamond and 30% SiC. The grain size of the hard abrasive grains is The size is 1 μm, and the thickness of the hard abrasive particles attached to the surface of the soft elastic abras...

Embodiment 2

[0102] A2: Add copper powder into molten fluid or liquid isoprene rubber, where the volume ratio of copper powder to isoprene rubber is 23:77.

[0103] Among them, the density of copper powder is 8.9g / cm 3 , the particle size is 0.5μm; the density of isoprene rubber is 0.94g / cm 3 , the hardness is Shore A 40, and the permanent deformation rate is 10%.

[0104] B2: Stir the copper powder and isoprene rubber evenly, and make the uniformly stirred mixture into a soft carrier with a particle size of 1mm, and the density of the prepared soft carrier is 2.8 / cm 3 .

[0105] C2: Hard abrasive grains are adhered to the surface of the soft carrier to form a soft elastic abrasive. The composition of the hard abrasive grains is 70% diamond and 30% SiC. The particle size of the hard abrasive grains is The size is 1 μm, and the thickness of the hard abrasive particles attached to the surface of the soft elastic abrasive is 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com