Jetting device and method for micro molten metal drops

A spray device and metal technology, applied to metal micro-droplet spray devices and fields, can solve problems such as low efficiency, and achieve the effect of reducing unstable conditions in the spray process or replacing nozzles for multiple disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

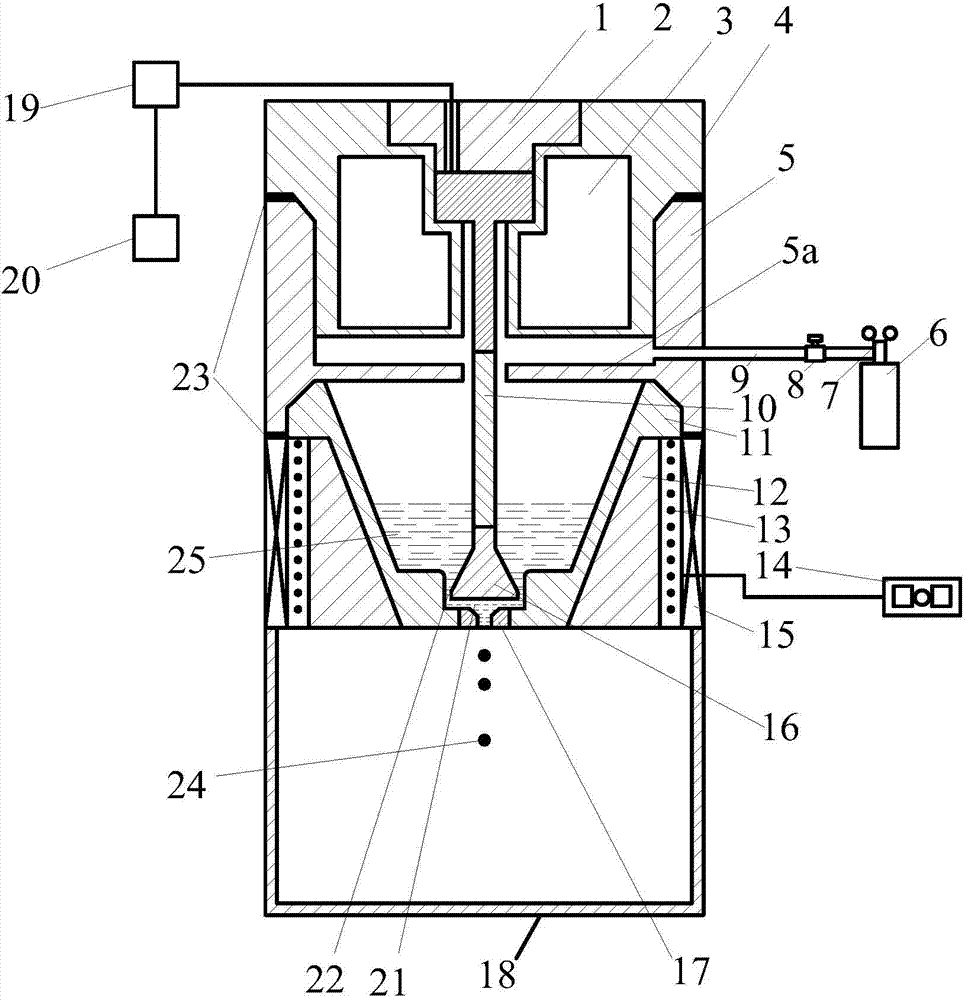

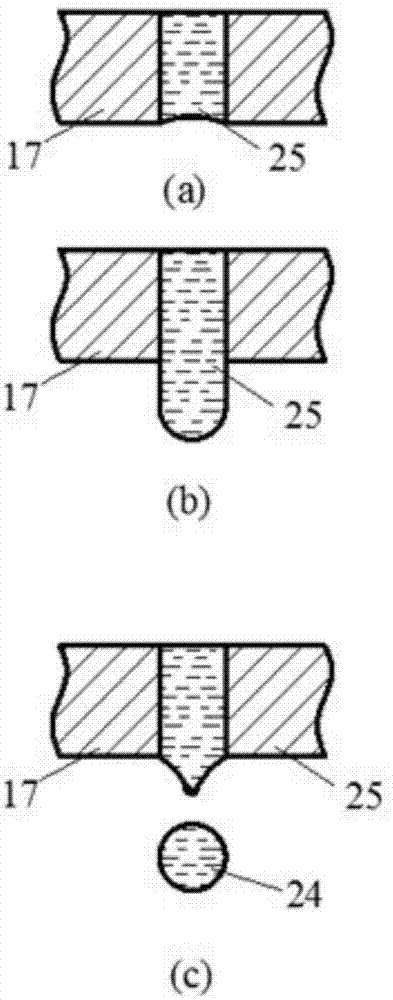

[0030] Embodiment 1: On-demand metal droplet injection

[0031] When using the device of the present invention to spray molten solder metal 25 (such as tin-lead alloys, tin-silver-copper alloys, etc.) The gas passes into the crucible 11 and the atomization chamber 18 to blow out the original air and reduce the oxygen content inside the crucible 11 and the atomization chamber 18 .

[0032] When using the device of the present invention to spray molten solder metal (such as tin-lead alloy, tin-silver-copper alloy, etc.) droplets, first set the temperature of the heating element 13 on the temperature controller 14 at 40 degrees Celsius above the melting point to heat and melt the solder metal And keep it for a period of time so that the molten metal 25 in the crucible 11 is completely melted and reaches a stable temperature, adjust the micro-pressure regulating valve 8 to make a micro-pressure difference between the interior of the crucible 11 and the atomization chamber 18, so t...

Embodiment 2

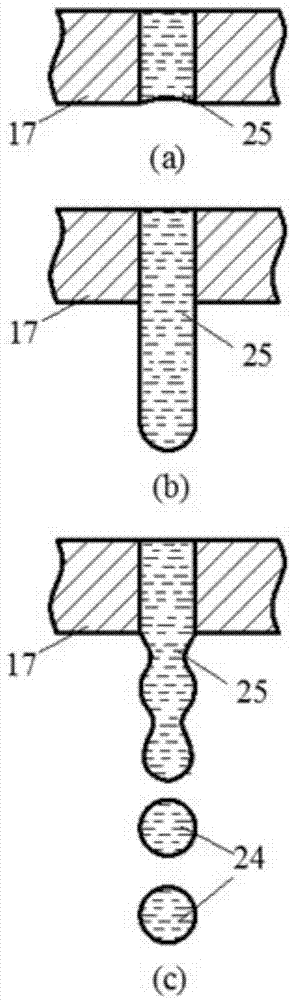

[0033] Embodiment 2: continuous metal micro-molten droplet jetting

[0034] When using the device of the present invention to spray molten solder metal 25 (such as tin-lead alloys, tin-silver-copper alloys, etc.) The gas passes into the crucible 11 and the atomization chamber 18 to blow out the original air and reduce the oxygen content inside the crucible 11 and the atomization chamber 18 .

[0035] When using the device of the present invention to spray molten solder metal 25 (such as tin-lead alloys, tin-silver-copper alloys, etc.) droplets, first set the temperature of the heating element 13 on the temperature controller 14 at 40 degrees Celsius above the melting point, and heat the solder metal Melt and keep it for a period of time to completely melt the molten metal 25 in the crucible 11 and reach a stable temperature. Through the inert gas source 6, the pressure reducing valve 7 and the micro-pressure regulating valve 8, the inside of the crucible 11 and the atomization...

Embodiment 3

[0036] Example 3: Nozzle cleaning.

[0037] When the nozzle is clogged and the micro-droplets cannot be ejected, the virtual instrument 20 is used to generate a continuous signal of a sinusoidal waveform with a frequency greater than 16KHz, which is amplified by the power amplifier 19 to drive the piezoelectric ceramic transducer 2, and the high-frequency and large-amplitude vibration makes the nozzle area The molten metal 25 produces ultrasonic cavitation phenomenon, and the micro-pressure regulating valve 8 is adjusted to generate a pressure difference between the inside of the crucible 11 and the atomization chamber 18, so that the impurities attached to the nozzles can be cleaned out, and the purpose of cleaning the clogged nozzles is realized, thereby reducing nozzle clogging The resulting injection process is unstable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com