Automatic diagnosing system for rolling bearing fault

A technology for automatic diagnosis and rolling bearings, applied in mechanical bearing testing, vibration testing, measuring devices, etc., can solve problems such as inability to qualitatively analyze bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

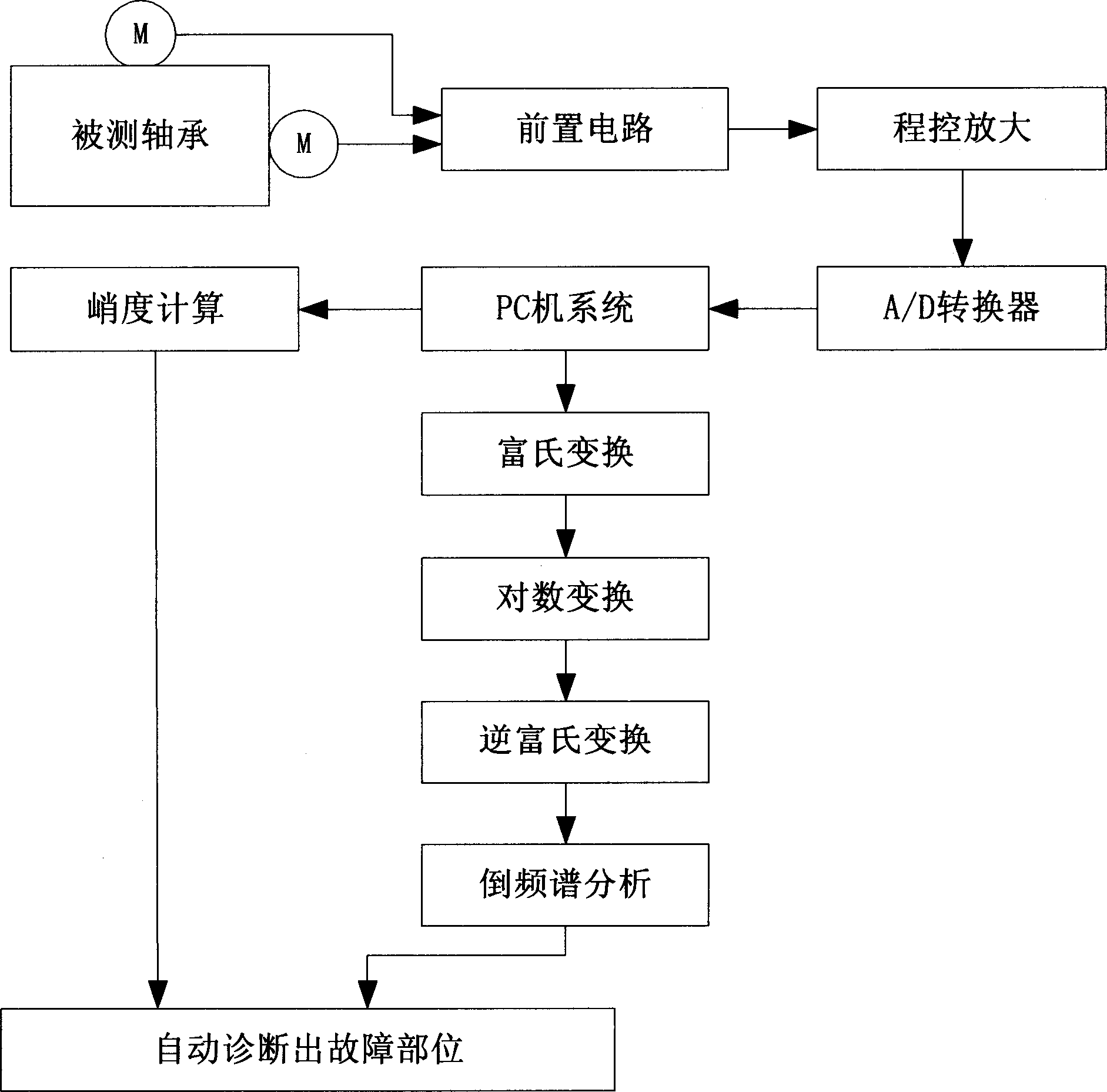

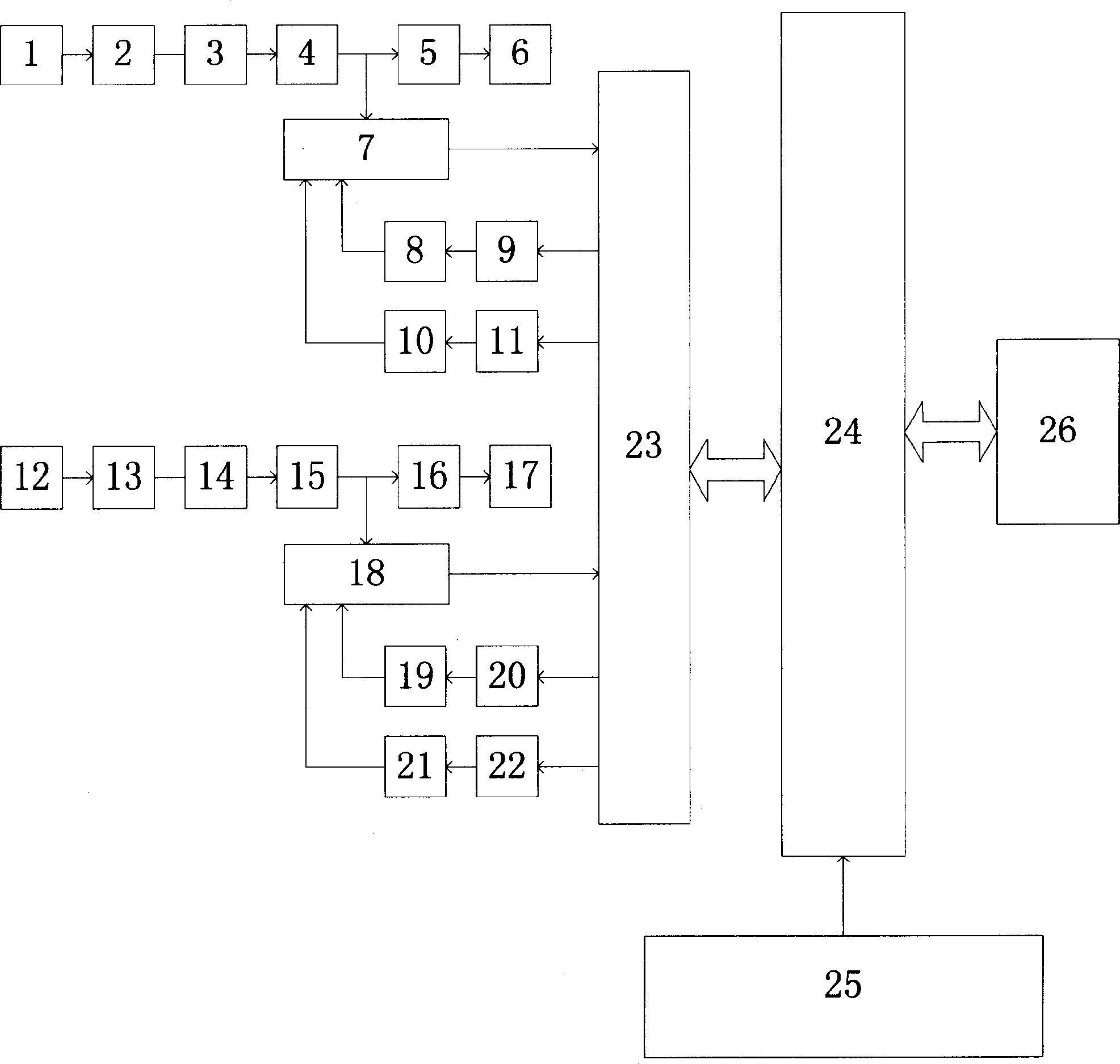

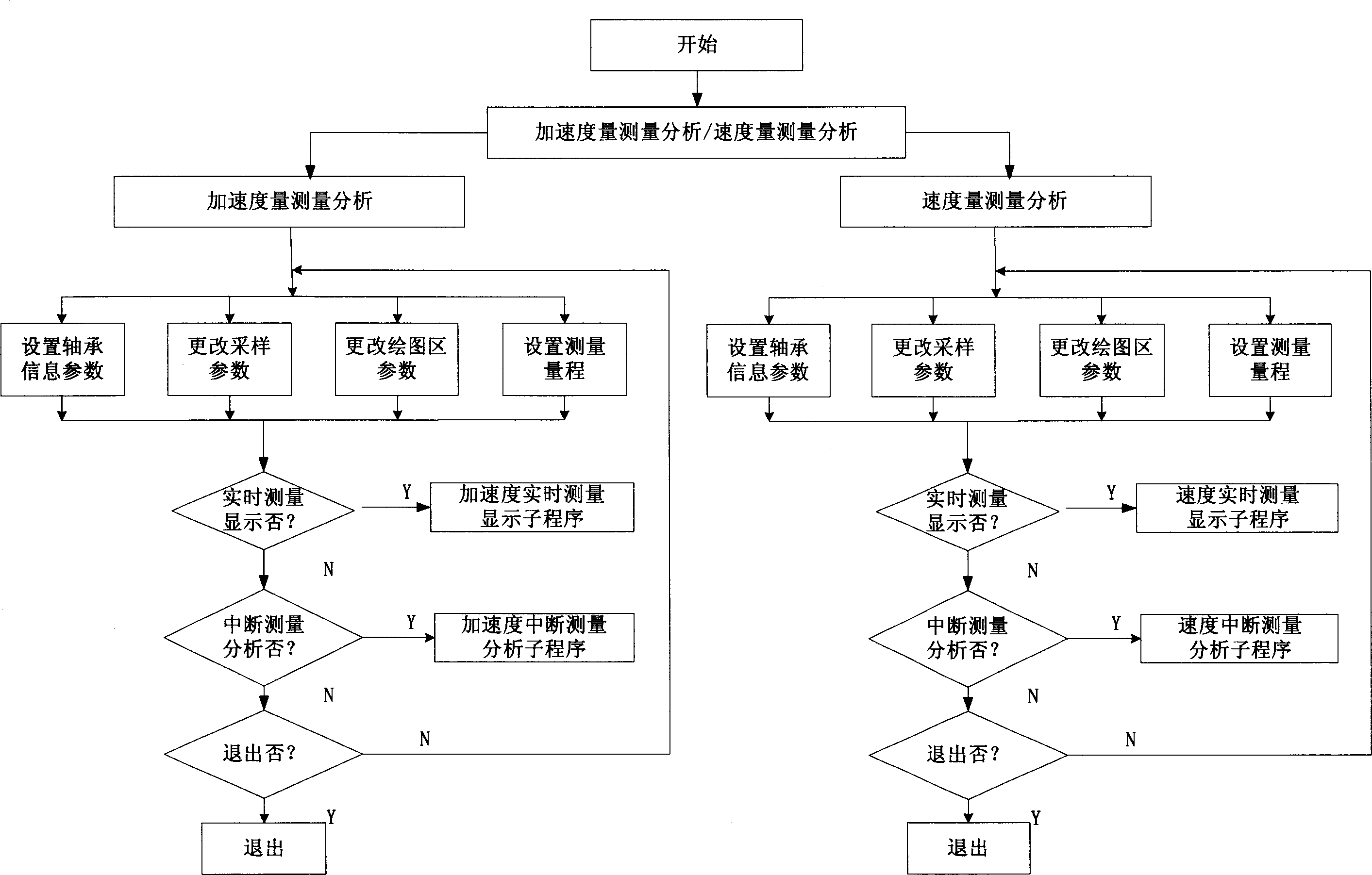

[0059] The invention provides a rolling bearing fault automatic diagnosis system, which utilizes bearing vibration test analysis and kurtosis analysis of bearing vibration, and through virtual instrument design and digital signal processing technology, the kurtosis value is automatically calculated by software, and then The spectrum analysis and comparison of the cepstrum can not only accurately test the vibration acceleration of the bearing, but also accurately test the vibration velocity of the bearing, and can perform multiple parameters such as time domain analysis, frequency domain analysis, and time-frequency domain joint analysis on the vibration of the bearing Quantitative and qualitative analysis, bearing abnormal sound and fault test analysis can also be carried out to achieve precise analysis of bearing vibration, and then compared with the fault characteristic frequency of the bearing or its frequency division and frequency multiplication characteristic values, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com