High-speed ink-jet printing module

An inkjet printing, high-speed technology, used in printing, typewriters, etc., can solve the problems of printing accuracy and low contact paper, and achieve the effects of easy operation and maintenance, good stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

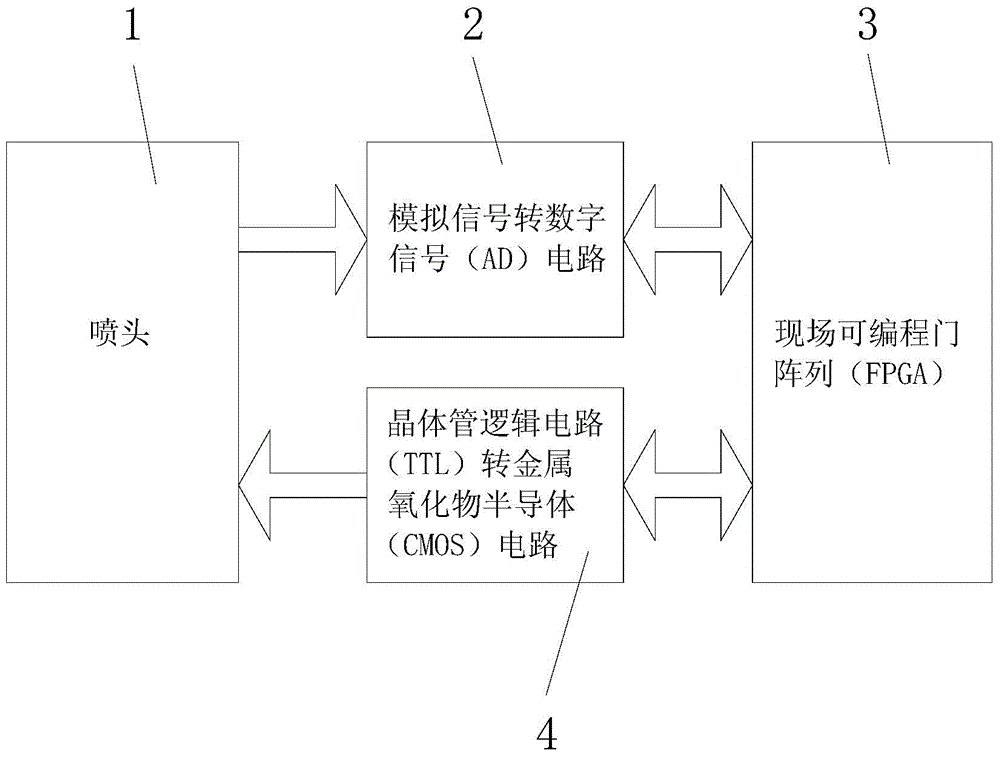

[0017] In further embodiments of the present invention, please continue to refer to figure 1 shown. The first circuit 2 is an AD circuit, and the FPGA chip control part 3 is driven and connected with the print nozzle 1 through the AD circuit. And the AD circuit is used to detect the connection of the print head 1 and the remaining amount of ink.

[0018] In a further embodiment of the present invention, the second circuit 4 is used to convert the TTL of the FPGA chip control part 3 into a CMOS circuit for driving the print head 1 .

[0019] In a further embodiment of the present invention, the second circuit 4 is a TTL-to-CMOS circuit, and the FPGA chip control part 3 is connected to the print nozzle 1 through the TTL-to-CMOS circuit.

[0020] On the basis of the above, the present invention also has the following usage methods:

[0021] Please continue to see figure 1 shown. The FPGA chip control part 3 outputs the data to be printed and the timing of the print head to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com