Photocuring 3D printing system and printing method

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of affecting the accuracy of the layer thickness of the three-dimensional model, affecting the printing speed, etc., to improve the light curing speed and printing speed, improve the printing accuracy, and improve the printing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

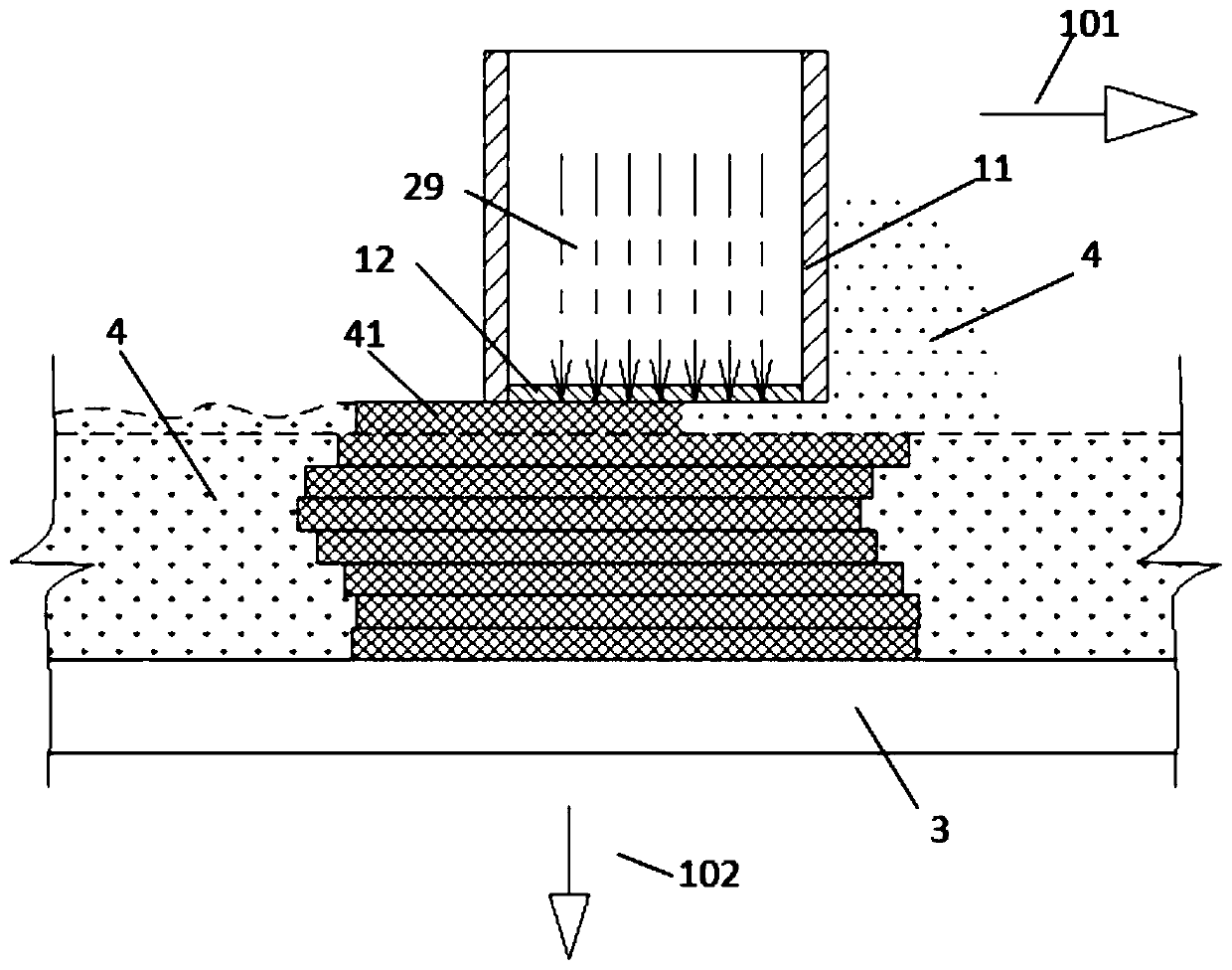

[0046] Such as figure 1 A light-curing 3D printing system shown includes a material carrier 3 and a material spreader 11 . Wherein, the spreader 11 is a scraper structure, at least part of the area on the spreader side of the spreader 11 is a light-transmitting area 12, and the light-transmitting area 12 can pass through light beams (or electromagnetic waves). The opposite side of the material container 11 and the material carrier 3, that is figure 1 The bottom of spreader 11 is shown. The light-transmitting area 12 can be realized by a light-transmitting plate, and the light beam 29 can pass through the light-transmitting area 12 to irradiate the photosensitive printing material 4 between the light-transmitting area 12 and the material carrier 3 . The spreader 11 may have a hollow structure, for example, the light-transmitting area 12 is disposed at the bottom of the hollow structure.

[0047] When printing, the driver ( figure 1 not shown in ) to drive the spreader 11 an...

Embodiment 2

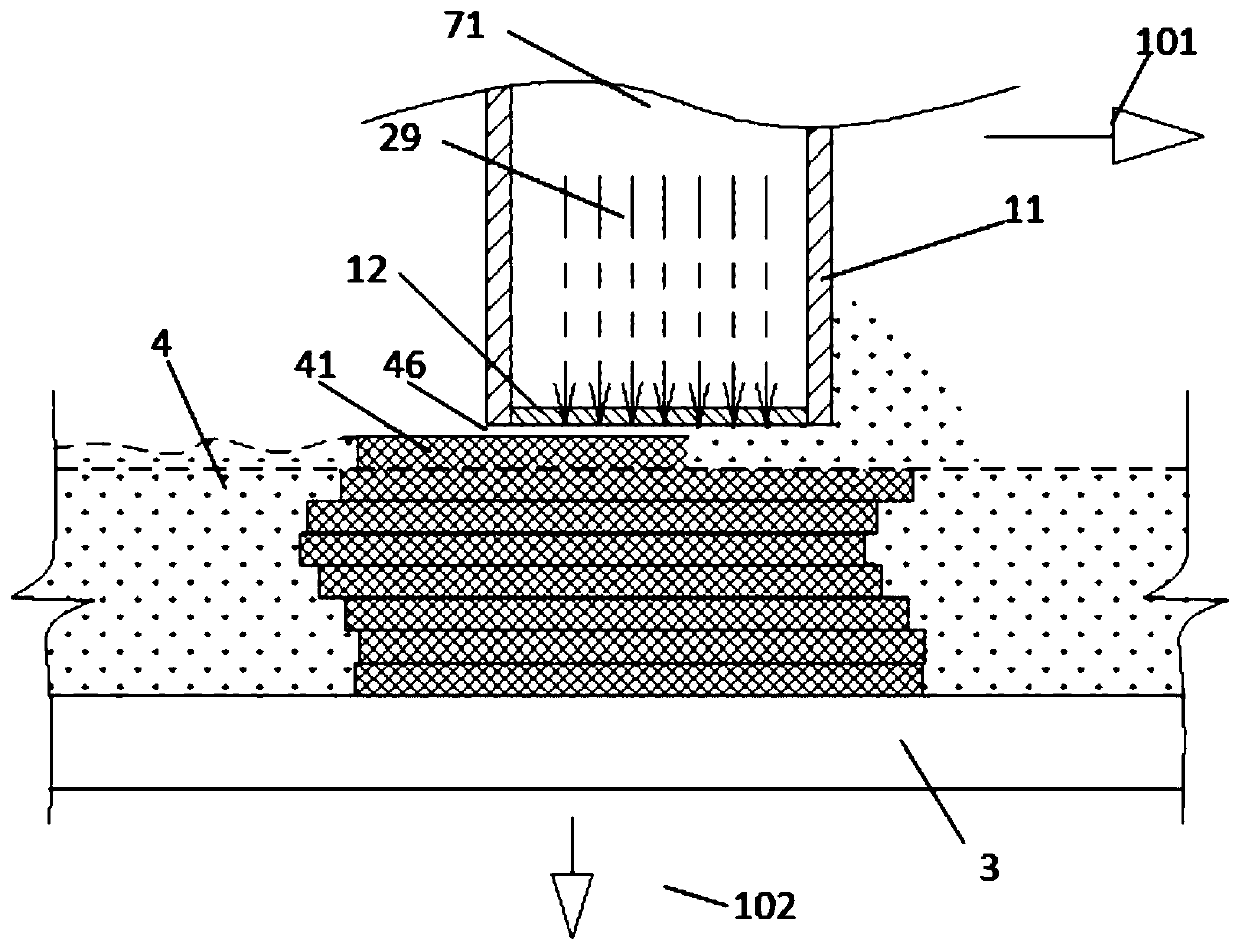

[0050] figure 2 Shown is a schematic structural diagram of Embodiment 2, which is different from Embodiment 1 in that a layer of isolation layer 46 is provided between the spreader 11 and the photosensitive printing material 4 to reduce the solidified layer 41 and the light-transmitting region 12. adhesion, the isolation layer 46 is in contact with the light-transmitting region 12 . The isolation layer 46 can be realized in various ways. For example, the light-transmitting region 12 of the spreader 11 can adopt a semi-permeable film, which can allow the light-curing inhibitor 71 (such as oxygen) with a certain pressure above to pass through the light-transmitting region 12. The pavement layer forms a photopolymerization dead zone, and the photopolymerization dead zone is in contact with the light-transmitting zone 12 . In the photopolymerization dead zone, the photosensitive printing material 4 will not be cured when the light beam 29 is irradiated, so that when the spreader...

Embodiment 3

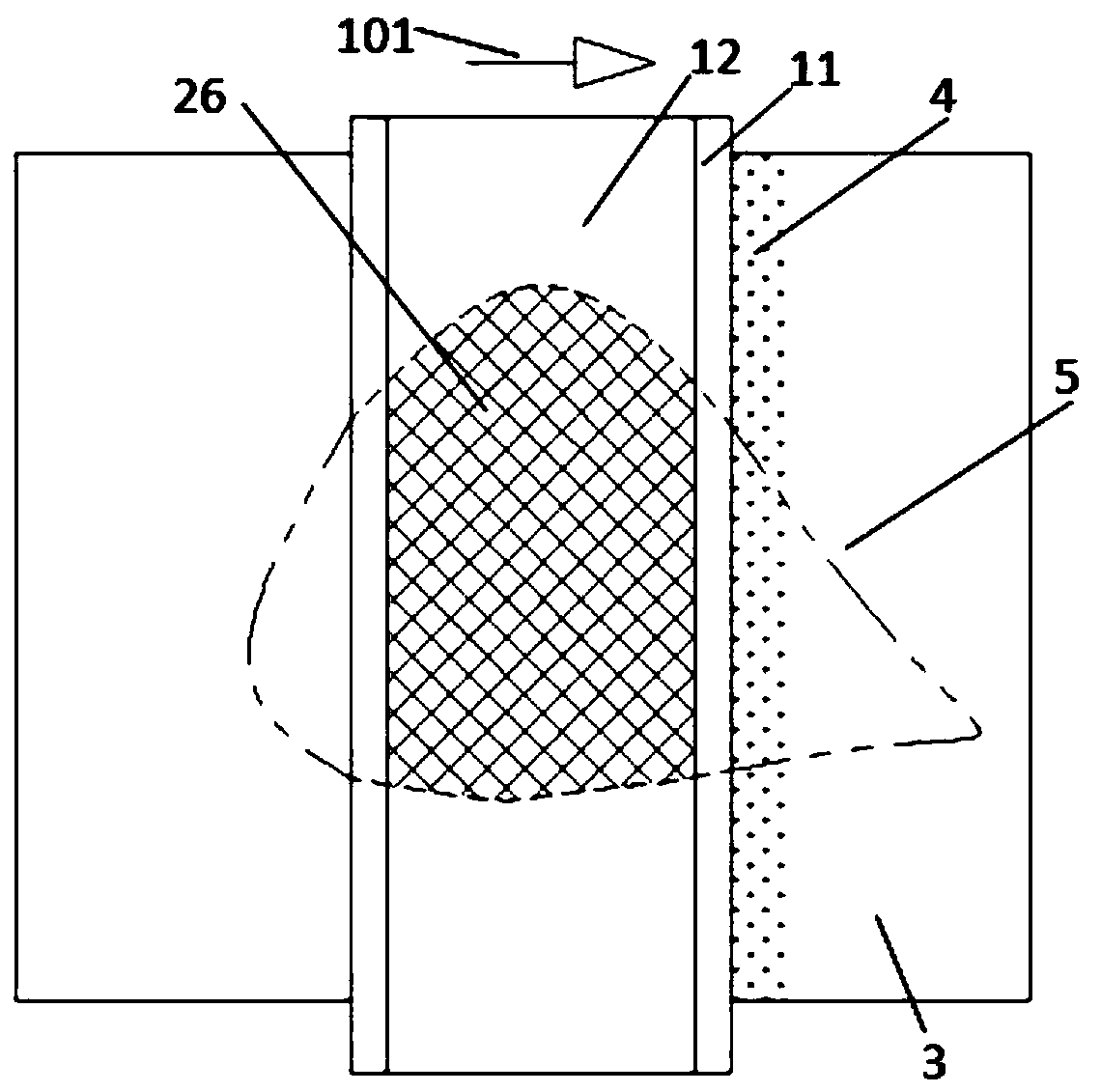

[0054] Figure 4 It is shown that the spreader 11 can be a closed structure, and a photocuring inhibitor 71 with a preset pressure, such as oxygen, can be set inside the light-transmitting area 12 on the side facing the material carrier 3 (as shown in the bottom). The transparent semi-permeable membrane can allow oxygen to pass through, and the top adopts a transparent plate 12a. The light beam 29 emitted by the light source 2 selectively illuminates the photosensitive printing material 4 between the spreader 11 and the material carrier 3 through the transparent plate 12 a and the light-transmitting area 12 . Such a structure can conveniently arrange the position of the light source 2 and control the pressure of the photocuring inhibitor 71 in the spreader 11 . In addition, a color nozzle 82 can also be provided. When the spreader 11 spreads the material and solidifies the printing material, the color nozzle 82 sprays the color material to the direction of the solidified laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com