Jet printing method for textile and special nozzle therefor

A printing method, a jet-type technology, applied in textiles and papermaking, printing, dyeing, etc., can solve the problems of slow printing speed and poor color mixing effect, and achieve the effect of improving printing speed and printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

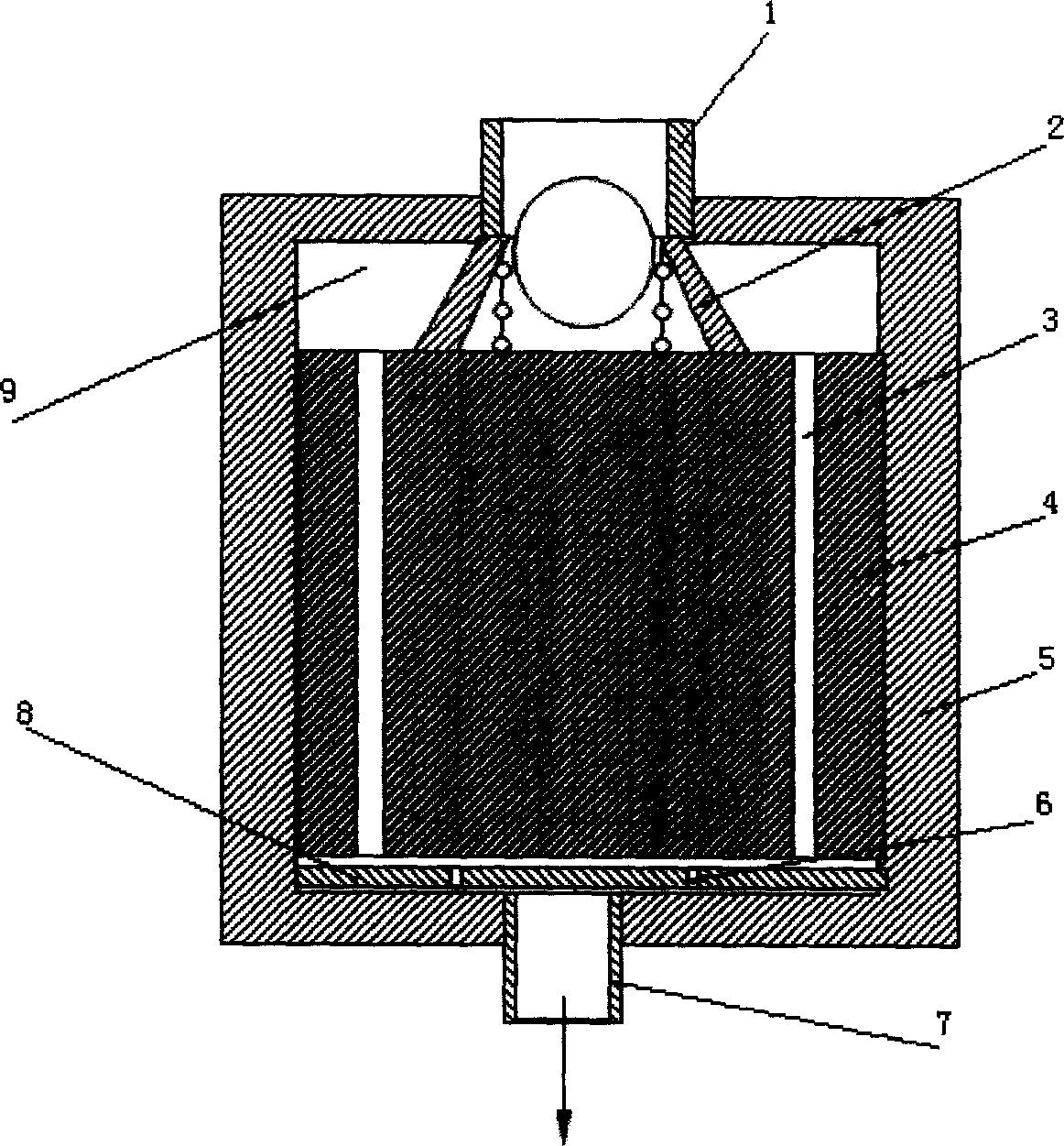

[0011] figure 2 Among them, the pipe body 5 of the nozzle is a cylindrical structure, the upper end cover and the lower end cover of the pipe body 5 are respectively equipped with a liquid inlet pipe 1 and a liquid outlet pipe 7, and the inner chamber 9 of the pipe body 5 is a cylindrical structure, and the inner chamber 9 The central axis of the tube coincides with the central axis of the tube body 5, the liquid inlet pipe 1 and the liquid outlet tube 7 communicate with the cylindrical inner cavity 9 of the tube body 5, and a cylindrical rotating core is installed in the inner cavity 9 of the tube body 5 4. The rotating core 4 is driven by a high-speed stepping motor, and the rotation and stop of the stepping motor are automatically controlled by a microcomputer. The central axis of the rotating core 4 coincides with the central axis of the inner cavity 9, and the rotating core 4 is centered on the axis There are a plurality of cylindrical infusion holes 3 evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com