Intaglio direct printing or flexo direct printing technology for polyester fabric and application of weak dispersion solvent ink in technology

A technology of polyester fabric and printing process, applied in the field of new printing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Preparation of dispersed weak solvent ink yellow for gravure direct printing and production process of gravure direct printing on polyester fabric 1

[0091] Production materials: degreased semi-finished polyester fabric

[0092] Dyeing chemicals: domestic disperse yellow S-6GL, cosolvent, surfactant, weak oxidizing agent, pH regulator, viscosity regulator, reducing cleaning solution (2g / L hydrosulfite, 2g / L soda ash).

[0093] Production equipment: mixer, ball mill, gravure printing machine, heat setting machine, flat car wash.

[0094] 1. Preparation of dispersed weak solvent ink yellow for gravure direct printing

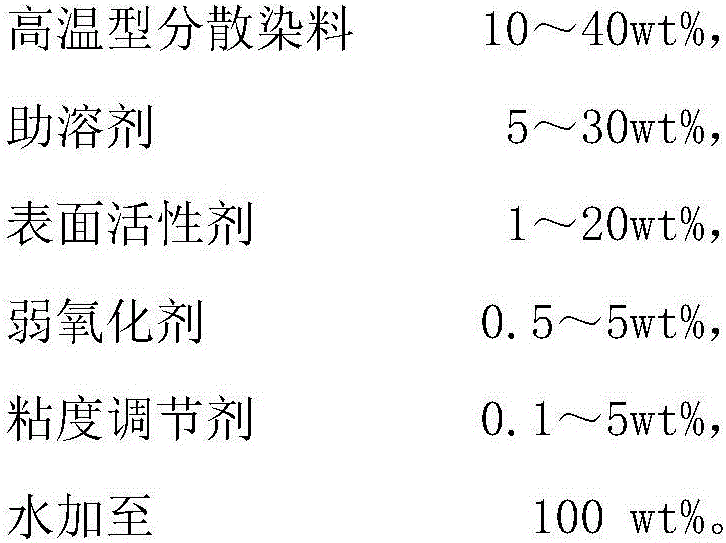

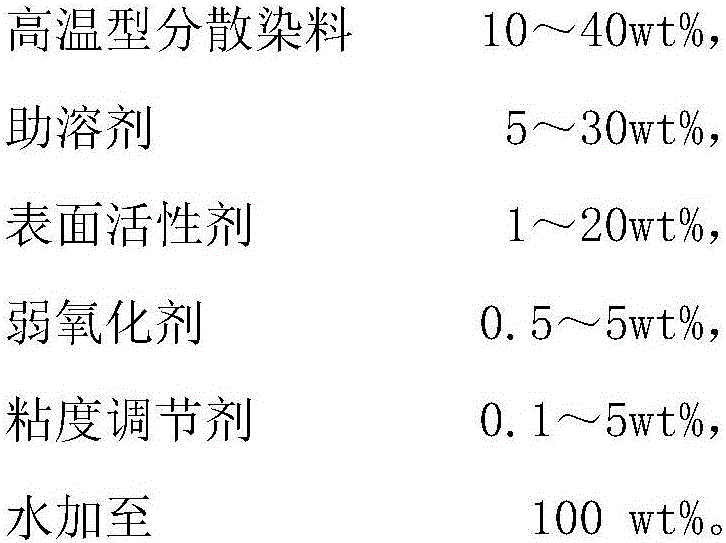

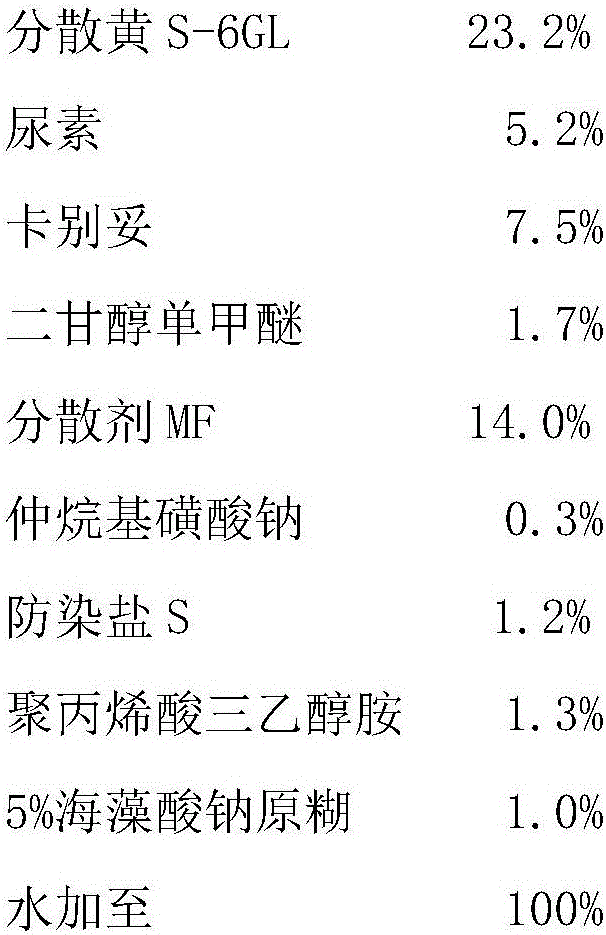

[0095] 1.1 Preparation prescription of disperse weak solvent ink yellow for gravure direct printing

[0096]

[0097] 1.2 Preparation process of dispersed weak solvent ink yellow for gravure direct printing

[0098] Weigh Disperse Yellow S-6GL, add a small amount of water, and adjust the dye into a slurry; add co-solvent, surfactant, weak oxidizing a...

Embodiment 2

[0107] Preparation of disperse weak solvent ink red for gravure direct printing and production process of gravure direct printing on polyester fabric 2

[0108] Production materials: degreased semi-finished polyester fabric

[0109] Dyeing chemicals: domestic disperse bright red S-3GFL, cosolvent, surfactant, anti-staining salt, pH regulator, viscosity regulator, reducing cleaning solution (2g / L hydrosulfite, 2g / L soda ash).

[0110] Production equipment: mixer, ball mill, gravure printing machine, heat setting machine, flat car wash.

[0111] 1. Preparation of disperse weak solvent ink red for gravure direct printing

[0112] 1.1 Preparation prescription of disperse weak solvent ink red for gravure direct printing

[0113]

[0114] 1.2 Preparation process of disperse weak solvent ink red for gravure direct printing

[0115] Weigh Disperse Scarlet S-3GFL, add a small amount of water, and adjust the dye into a slurry; add co-solvent, surfactant, weak oxidizing agent, and ...

Embodiment 3

[0124] Preparation of disperse eco-solvent ink blue for gravure direct printing and production process of gravure direct printing on polyester fabric 3

[0125] Production materials: degreased semi-finished polyester fabric

[0126] Dyeing chemicals: domestic disperse turquoise blue S-GL, co-solvent, surfactant, weak oxidizing agent, pH regulator, viscosity regulator, reducing cleaning solution (2g / L hydrosulfite, 2g / L soda ash).

[0127] Production equipment: mixer, ball mill, gravure printing machine, heat setting machine, flat car wash.

[0128] 1. Preparation of disperse weak solvent ink blue for gravure direct printing

[0129] 1.1 Preparation prescription of disperse eco-solvent ink blue for gravure direct printing

[0130]

[0131] 1.2 Preparation process of disperse weak solvent ink blue for gravure direct printing

[0132] Weigh Disperse Turquoise Blue S-GL, add a small amount of water, and adjust the dye into a slurry; add co-solvent, surfactant, weak oxidizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com