3D printing device and printing method

A 3D printing and printing platform technology, which is applied in the direction of ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of difficult printing solution, unprintable, low printing accuracy, etc., and achieve uniform and accurate curing thickness, extended The effect of increasing the service life and increasing the printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

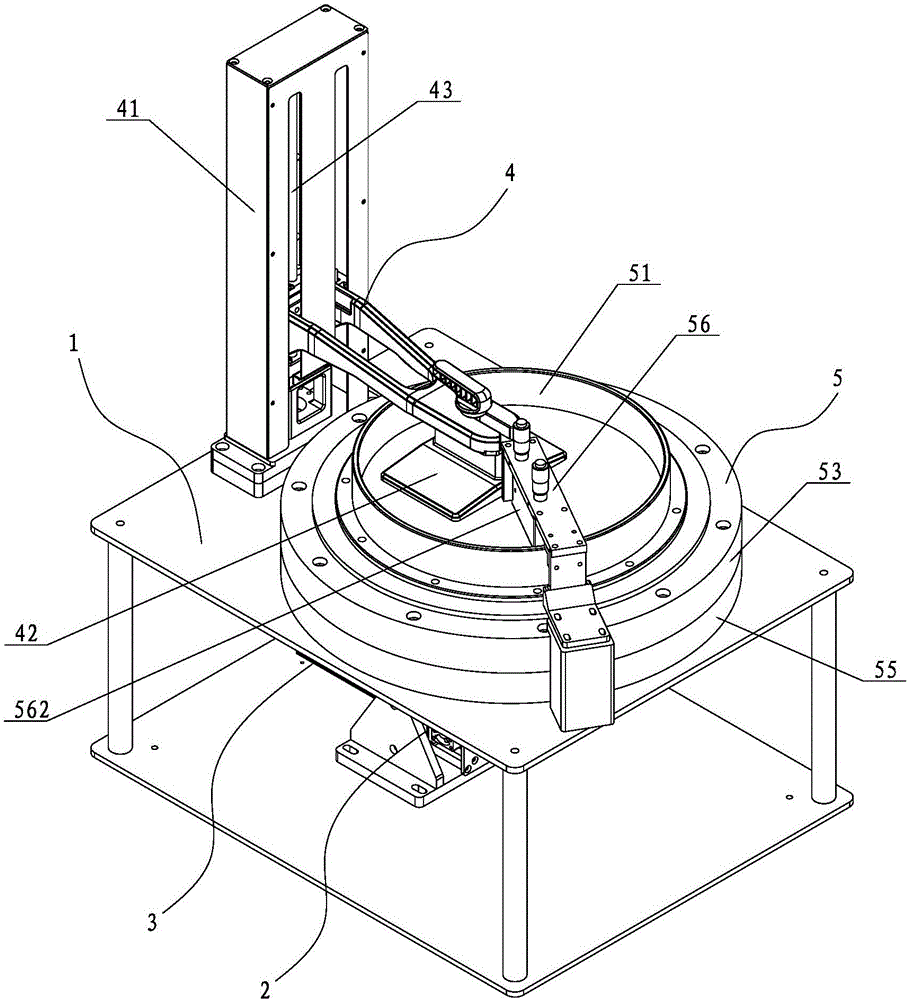

[0030] Such as figure 1 As shown, a 3D printing device includes a base 1, an exposure mechanism 2 arranged in the base 1, a control mechanism 3, a printing mechanism 4 and a liquid holding mechanism 5 arranged on the base 1, wherein the The printing mechanism 4 includes a module 41 and a printing platform 42 slidably installed on the module 41. In this embodiment, the printing platform 42 slides up and down through a lead screw 43 vertically arranged on the module 41. The printing platform 42 It is connected with the lead screw 43, and the lead screw 43 is connected with the lead screw motor. The lead screw 43 is driven to rotate by the lead screw motor, and then drives the printing platform 42 to move. During the printing process, the printing platform 42 can freely rise / fall. The control mechanism 3 is controlled by a microprocessor, and the control mechanism 3 is respectively connected with the exposure mechanism 2, the printing mechanism 3 and the liquid holding mechanism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com