Digital printing machine and digital printing system

A digital printing machine and digital printing technology, applied in printing, typewriters, printing devices, etc., can solve the problems of slow printing speed, low efficiency, and small production capacity, and achieve the effect of fast printing speed, high efficiency, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An embodiment of the digital printing machine of the present invention, the digital printing machine may include:

[0052] A frame, a print head, a mobile platform, and at least two workbenches installed on the mobile platform for installing objects to be printed;

[0053] And at least one mobile platform transmission device (such as one, two or more mobile platform transmission devices) connected to the mobile platform for driving the mobile platform to move, and connected to the print head for driving the printing The printing nozzle transmission device for nozzle movement; the mobile platform transmission device and the printing nozzle transmission device are installed on the frame.

[0054]In practical applications, the printing nozzle transmission device can be used to drive the printing nozzle to move left and right; the mobile platform transmission device is used to drive the mobile platform to move back and forth; To drive the mobile platform to move left and r...

Embodiment 2

[0064] In order to facilitate a better understanding of the technical solutions of the embodiments of the present invention, a digital printing machine with a specific structure is used as a more specific description below.

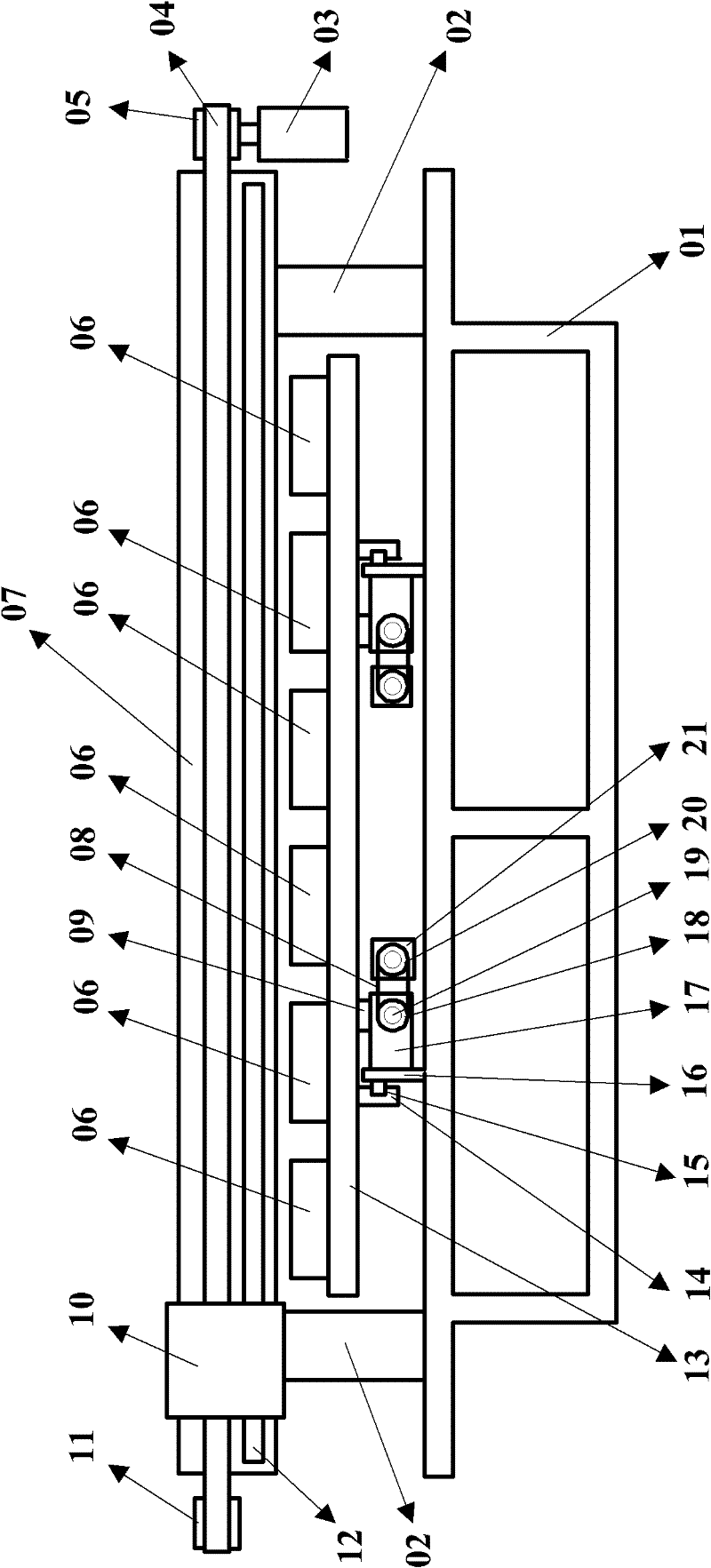

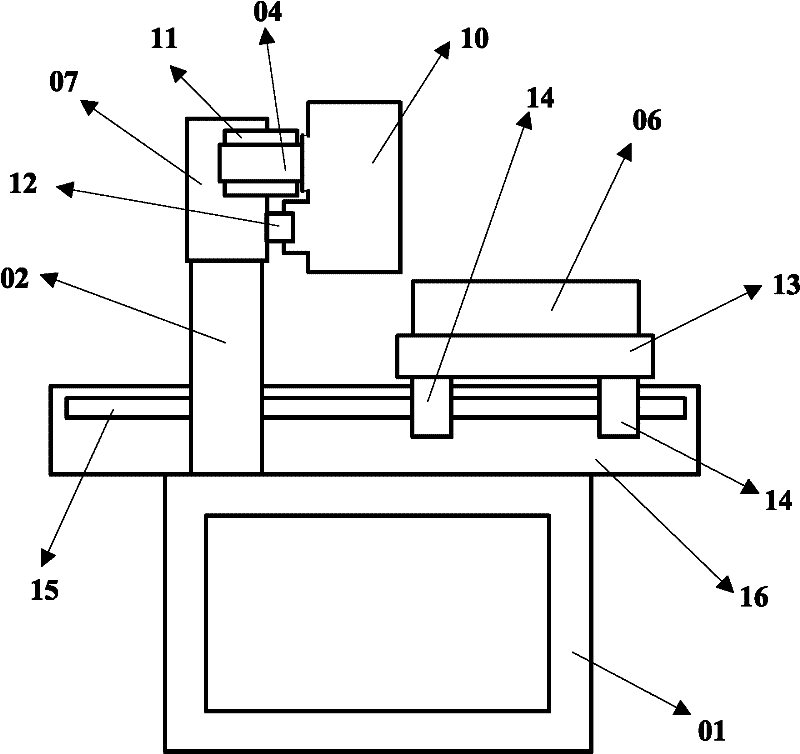

[0065] see figure 1 and figure 2 , figure 1 It is a front view schematic diagram of a digital printing machine structure provided by Embodiment 2 of the present invention; figure 2 It is a schematic side view of the structure of a digital printing machine provided by Embodiment 2 of the present invention.

[0066] The digital printing machine provided in this embodiment may include:

[0067] Frame 01, print nozzle 10, mobile platform 13, at least two workbenches 06 ( figure 1 In the example, there are 6 workbenches);

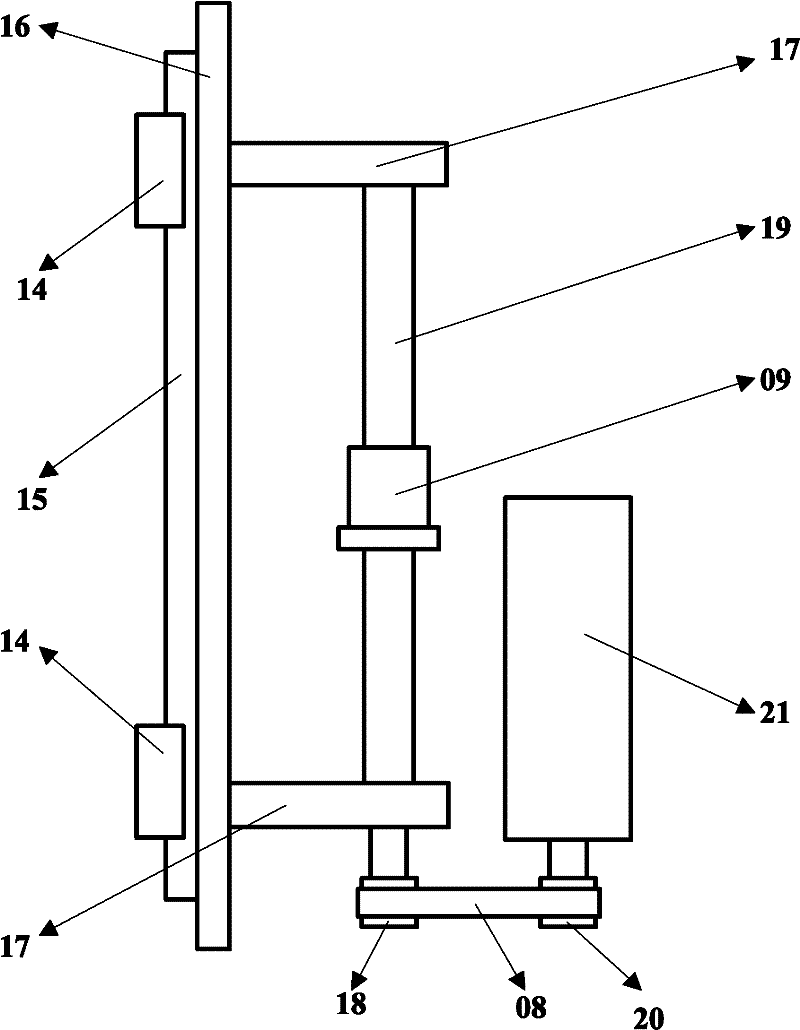

[0068] The mobile platform 13 is connected to be used to drive at least one mobile platform transmission device ( figure 1 2 in the example), the print head transmission device connected to the print head 10 for driving the print he...

Embodiment 3

[0085] A digital printing system provided by an embodiment of the present invention may include: a digital printing machine 410, and a control device 420 for controlling the digital printing machine 410 to perform digital printing;

[0086] Among them, the digital printing machine 410 may include:

[0087] Frame, print nozzle, mobile platform, at least two workbenches installed on the mobile platform for installing objects to be printed; and at least one mobile platform transmission device connected to the mobile platform for driving the mobile platform to move (For example, it can be one, two or more mobile platform transmission devices), the print nozzle transmission device connected with the print nozzle to drive the print nozzle to move; the mobile platform transmission device and the print nozzle transmission device are installed on the frame superior.

[0088] In practical applications, the printing nozzle transmission device can be used to drive the printing nozzle to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com