Light-cured printing equipment and method

A printing device and light curing technology, applied in the field of 3D printing technology, can solve the problems of unfavorable working life and energy consumption of two-photon lasers during printing, and achieve the effect of fast printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0038] The invention can be embodied in various forms, some examples of which are described below.

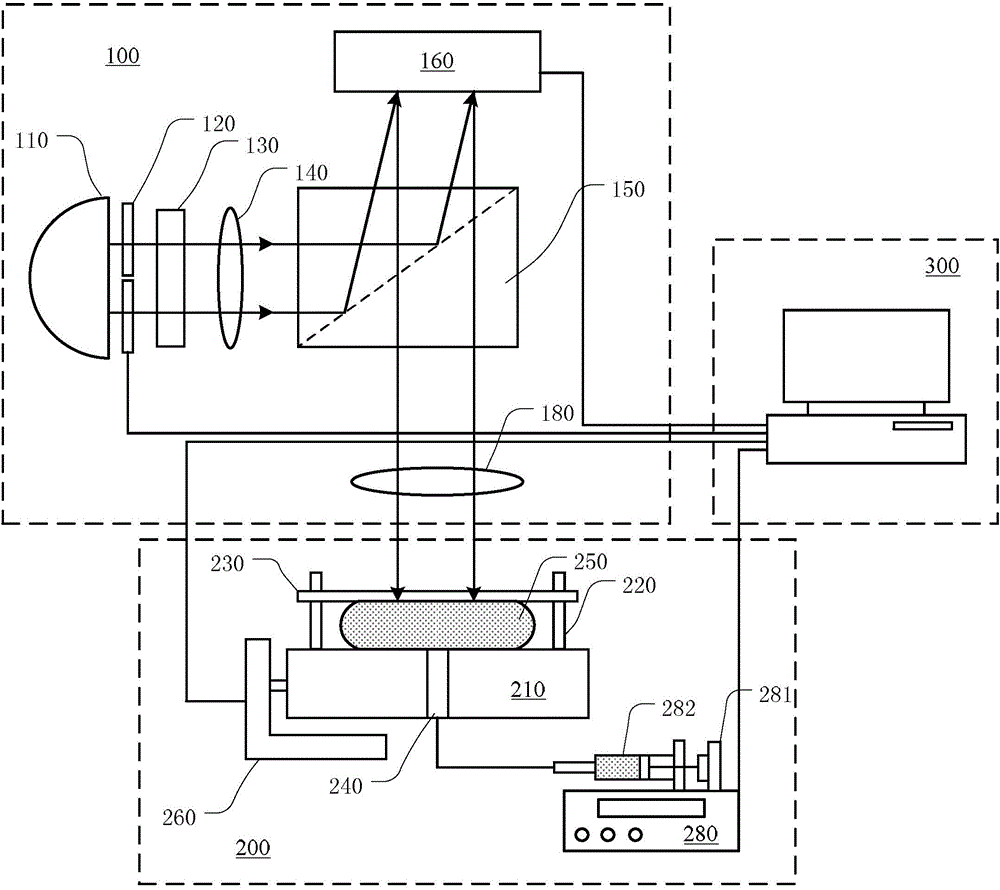

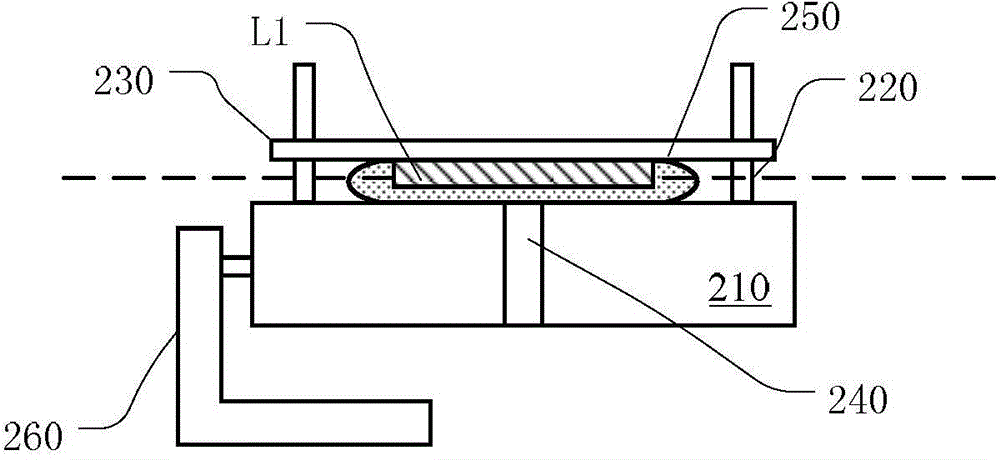

[0039] figure 1 A schematic diagram of the basic structure of a photocuring printing device according to an embodiment of the present invention is shown. The photocuring printing device includes a digital projection unit 100 , a photosensitive hydrogel curing unit 200 and a computer control unit 300 .

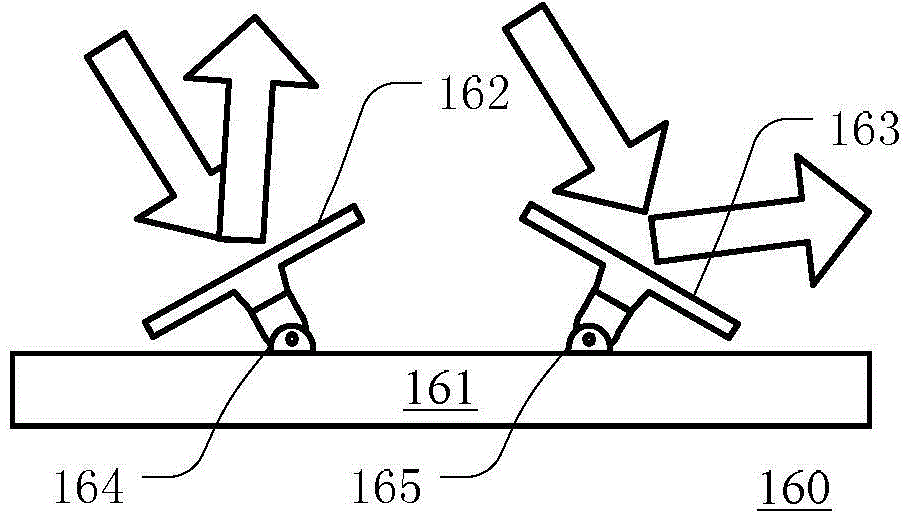

[0040]The digital projection unit 100 includes an ultraviolet (UV) light source 110 , a shutter 120 , a filter 130 , a condenser 140 , a total internal reflection (TIR) prism 150 , a digital micromirror device (DMD) 160 and a projection lens 180 . UV light is emitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com