3D printed controllable porous hydroxyapatite bioceramic stent and preparation method thereof

A technology of porous hydroxyapatite and hydroxyapatite, applied in bone implants, additive processing, etc., can solve the problems of low efficiency and achieve low viscosity, good fluidity, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Add the hydroxyapatite powder to the premix of resin, dispersant, defoamer and other additives until the powder reaches 40vol%, use zirconia grinding balls with a diameter of 3-5mm, the ball-to-material ratio is 1:2, and the rotation speed 100r / min, ball milling for 4h to prepare hydroxyapatite slurry for photocuring printing.

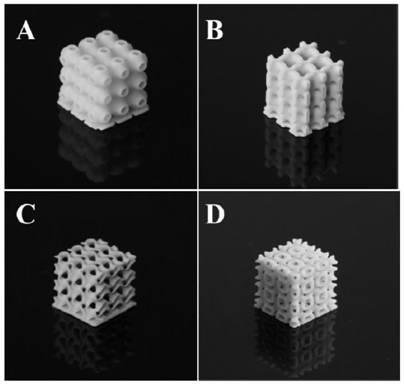

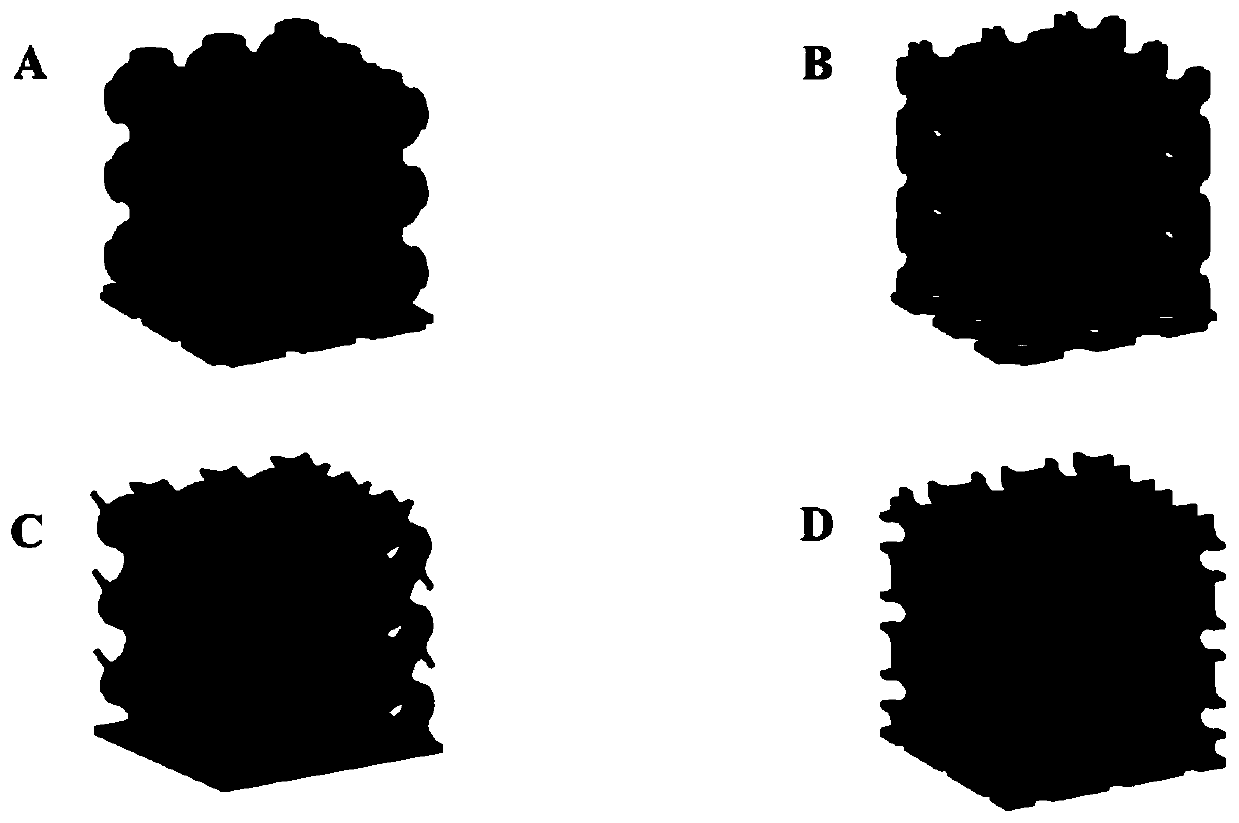

[0031] 2. Use the Magics three-dimensional mapping software to draw a p-cell model with a bionic TPMS structure and a theoretical porosity of 85%, such as figure 2 As shown in A.

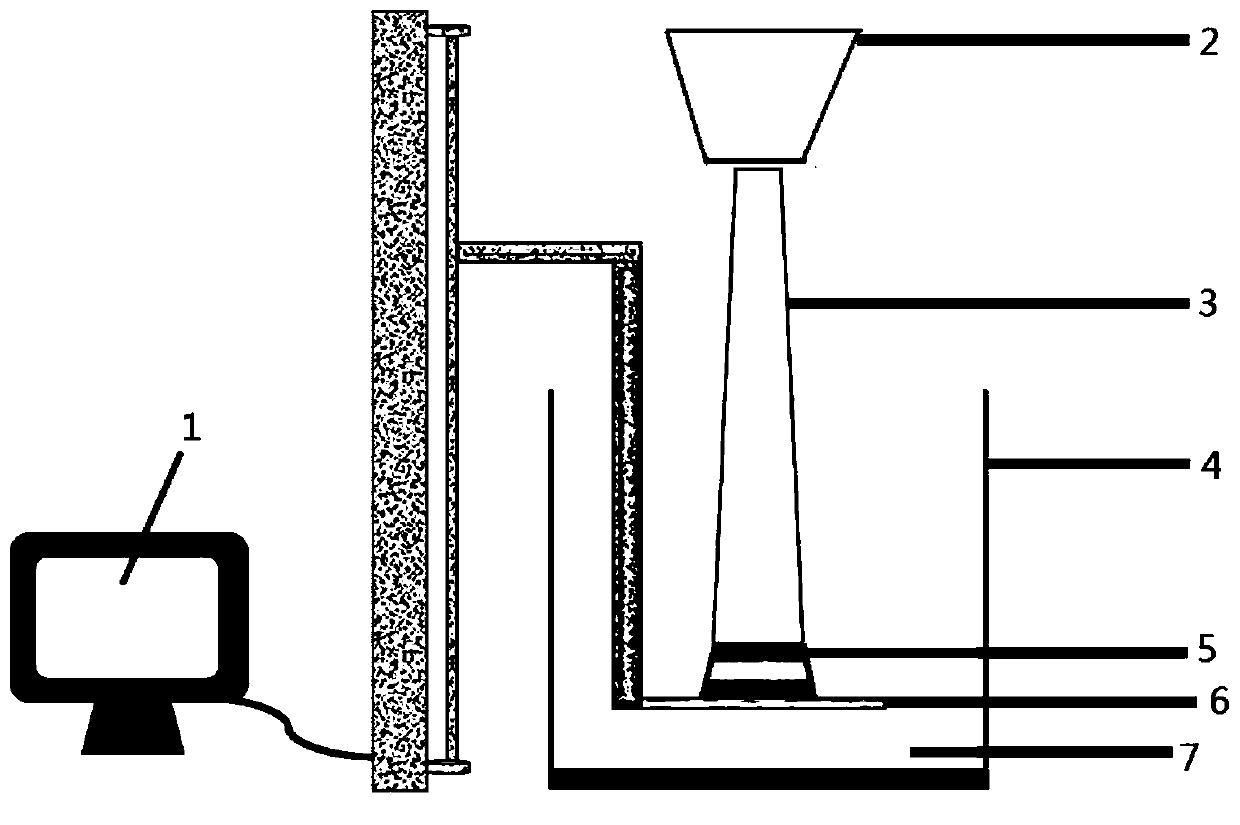

[0032] 3. Put the hydroxyapatite ceramic-resin slurry under the DLP light curing machine for printing, the wavelength is 405nm, and the light intensity is 10000μw / cm 2, The thickness of the printing layer is 50 μm, the exposure time of the first layer is 3s, and the exposure time of the single layer is 1s, and the printing is accumulated and formed layer by layer.

[0033] 4. Put the printed ceramic green body into an ordinary pressureless muffle furnace for deg...

Embodiment 2

[0036] 1. Add the hydroxyapatite powder to the premix of resin, dispersant, defoamer and other additives until the powder reaches 40vol%, use zirconia grinding balls with a diameter of 3-5mm, the ball-to-material ratio is 1:2.5, and the speed 110r / min, ball milling for 6h to prepare hydroxyapatite slurry for photocuring printing.

[0037] 2. Use the Magics 3D mapping software to draw the S-14 model with a bionic TPMS structure and a theoretical porosity of 85%, such as figure 2 Shown in B.

[0038] 3. Put the hydroxyapatite ceramic-resin slurry under the DLP light curing machine for printing, the wavelength is 405nm, and the light intensity is 10000μw / cm 2,The thickness of the printing layer is 50 μm, the exposure time of the first layer is 5s, and the exposure time of the single layer is 1s, and the printing is accumulated layer by layer.

[0039] 4. Put the printed ceramic green body into an ordinary pressureless muffle furnace for degreasing and sintering. The temperatur...

Embodiment 3

[0042] 1. Add the hydroxyapatite powder to the premix of resin, dispersant, defoamer and other additives until the powder reaches 45vol%, use zirconia grinding balls with a diameter of 3-5mm, the ball-to-material ratio is 1:3, and the rotation speed 120r / min, ball milling for 6h to prepare hydroxyapatite slurry for photocuring printing.

[0043] 2. Use Solidworks three-dimensional drawing software to draw a G-yroid model with a bionic TPMS structure and a theoretical porosity of 90%, such as figure 2 C shows.

[0044] 3. Put the hydroxyapatite ceramic-resin slurry under the DLP light curing machine for printing, the wavelength is 405nm, and the light intensity is 10000μw / cm 2, The thickness of the printing layer is 50 μm, the exposure time of the first layer is 2s, and the exposure time of the single layer is 2s, and the printing is accumulated and formed layer by layer.

[0045] 4. Put the printed ceramic green body into an ordinary pressureless muffle furnace for degreasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com