Preparation method of porous sound absorption structure composite material

A technology for composite materials and products, which is applied in the field of composite material preparation, can solve problems such as poor control of pore size, quantity and arrangement, unstable sound absorption performance of materials, failure of sound absorption layer peeling, etc., to achieve product size The effect of high stability, light weight and fast printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

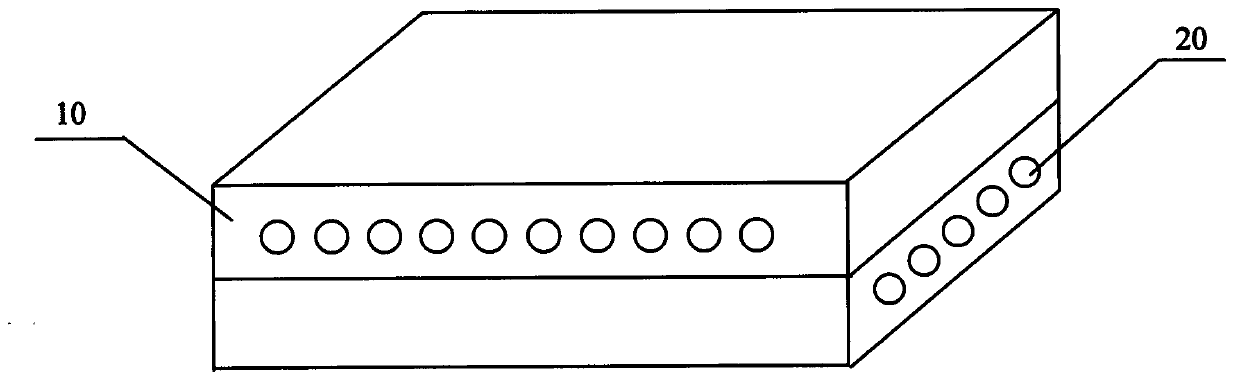

Embodiment 1

[0024] (1) Clean the mold and apply a release agent;

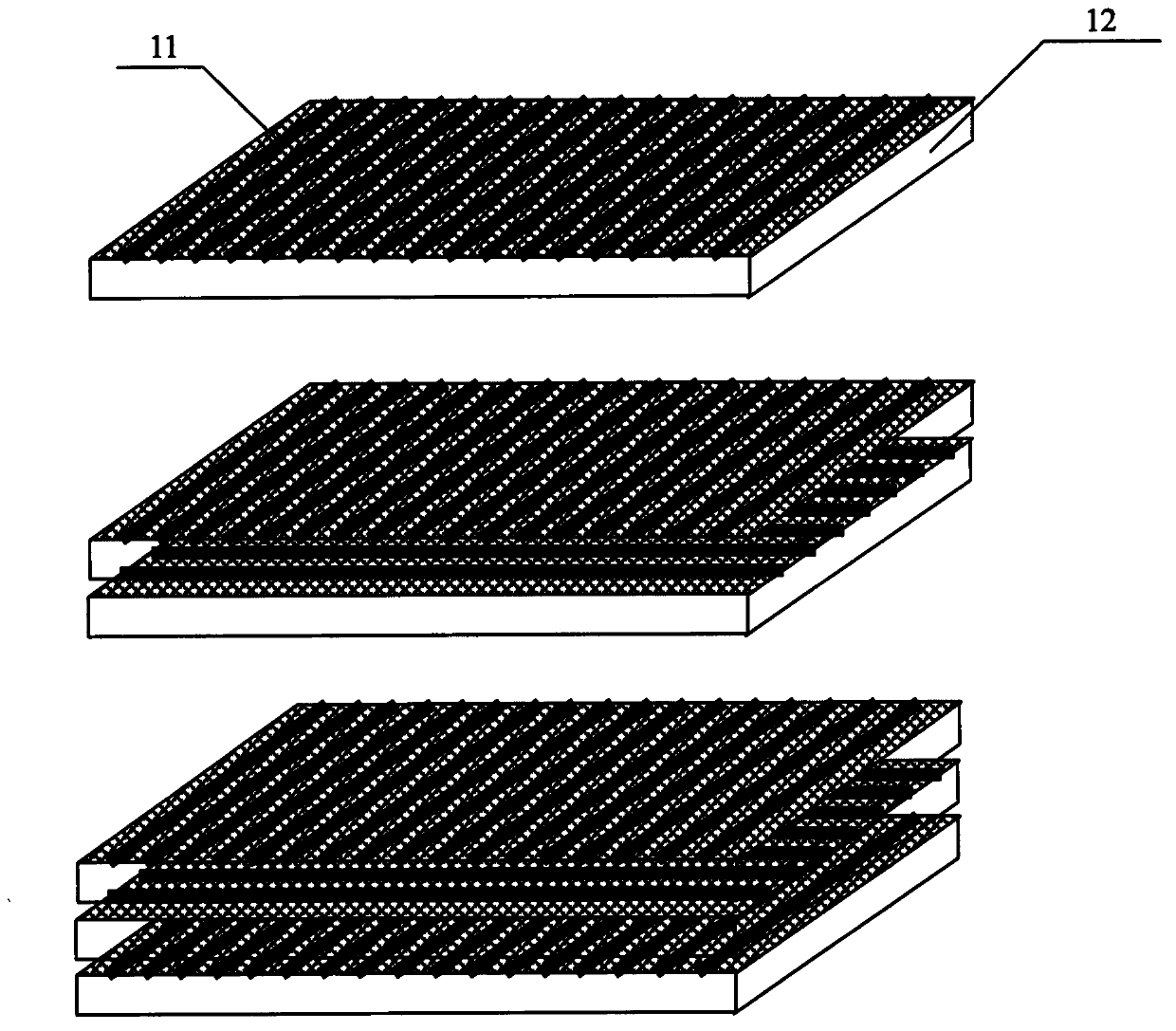

[0025] (2) Lay 3 layers of pre-woven glass fiber cloth with a content of 40% on top of each other. Between each layer, 3D printers use wax materials to print 10 inter-layers on the high-performance fiber cloth with an area of 210mm×297mm. Parallel three-dimensional straight pipes, the position of the pipes between two adjacent layers is spatially orthogonal, the pipe diameter is 3mm, and the distance between the centerlines of two adjacent prefabricated pipes is 4mm;

[0026] (3) Place the prefabricated part in the mold, close the mold and fix it, inject epoxy resin, and adopt molding process to form;

[0027] (4) curing demoulding, trimming the glass fiber reinforced epoxy resin matrix composite material that makes;

[0028] (5) Place the product in an oven and heat it at a temperature of 40°C;

[0029] (6) Take out the product after 45 minutes to obtain a porous sound-absorbing structure composite material the size o...

Embodiment 2

[0031] (1) Clean the mold and apply a release agent;

[0032] (2)) The carbon fiber with a content of 15% and the glass fiber with a content of 35% are pre-woven and placed in layers, a total of 5 layers, each layer is made of 3D printers using PLA environmental protection materials with an area of 210mm×297mm 40 parallel three-dimensional straight pipes are printed on the high-performance fiber cloth. The pipe positions between two adjacent layers are spatially orthogonal, the diameter of the pipes is 1 mm, and the distance between the centerlines of the prefabricated pipes on two adjacent layers is 2 mm;

[0033] (3) Place the prefabricated part in the mold, close the mold and fix it, inject epoxy resin, and adopt molding process to form;

[0034] (4) curing demoulding, trimming the obtained high-performance fiber reinforced epoxy resin-based composite material;

[0035] (5) Place the product in an oven and heat it at a temperature of 180°C;

[0036] (6) Take out the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com