Automatic monitoring method for printing machine ink-jet head and device thereof

An automatic monitoring and inkjet head technology, applied in printing devices, printing and other directions, can solve the problem that the monitoring method cannot be directly applied to inkjet printers, affecting the printing quality, etc., to achieve easy implementation and operation, good work stability, and processing. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

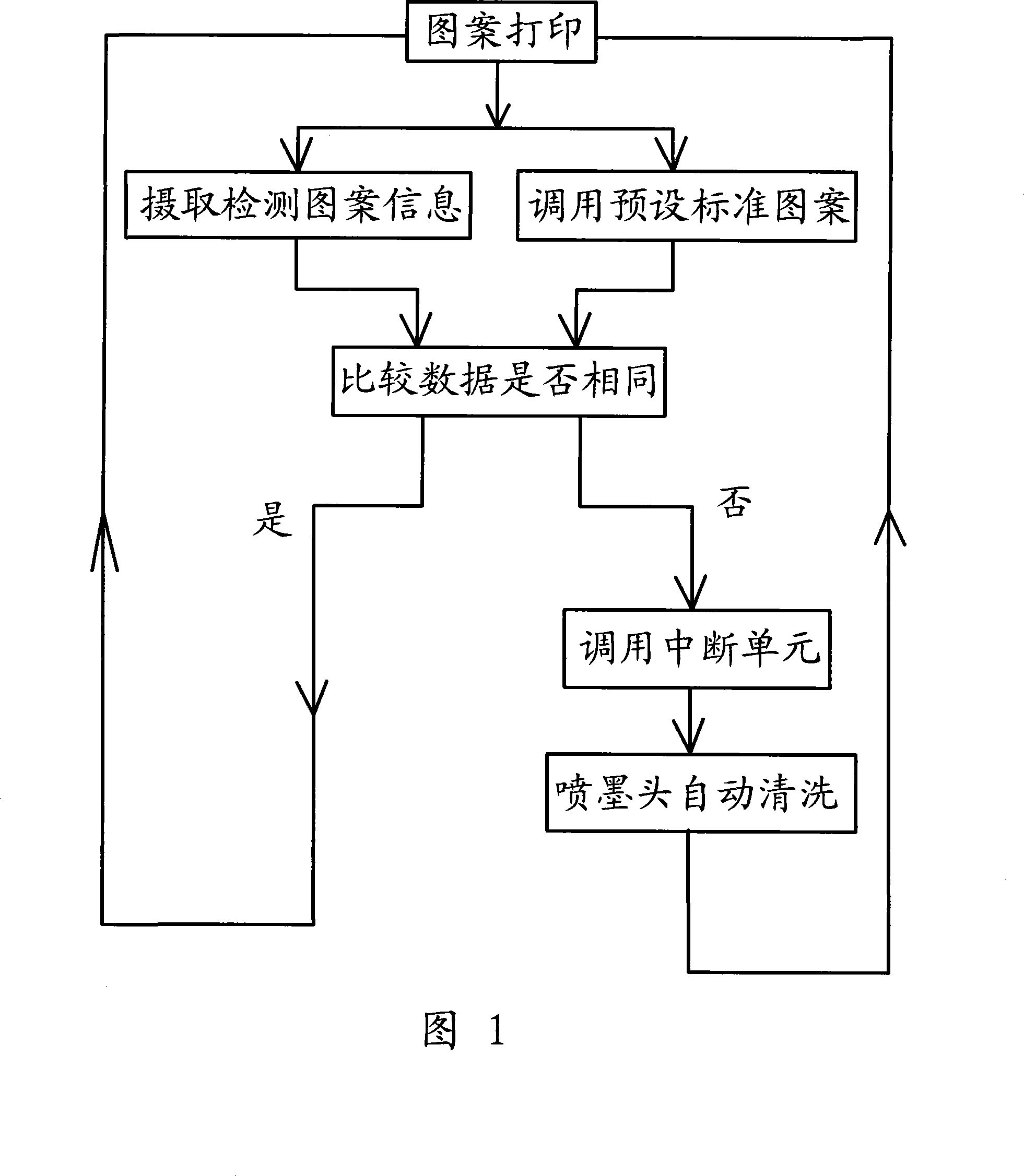

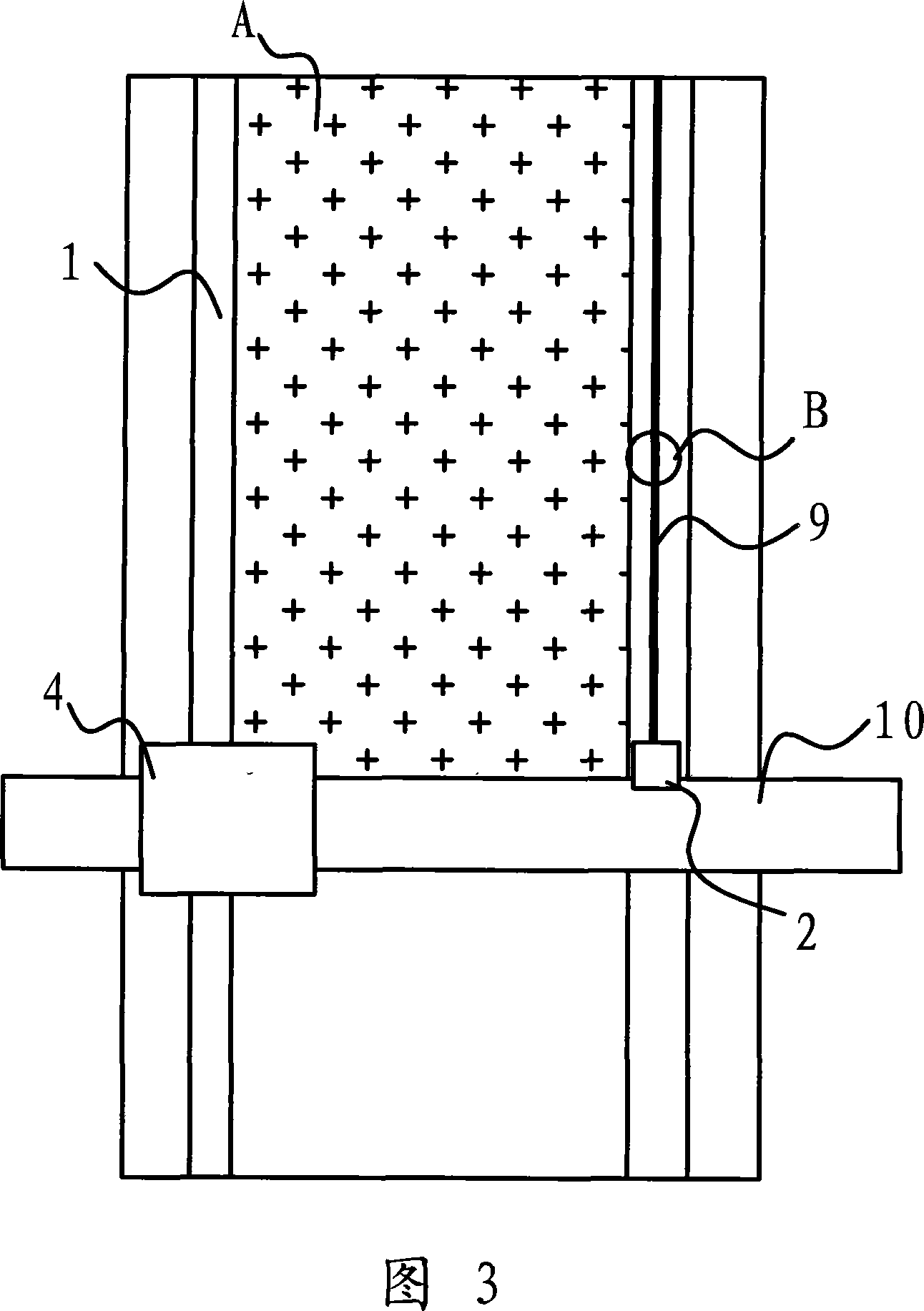

[0034] As shown in Figure 1, the automatic monitoring method of the inkjet head of this printer is realized through the following process: A. In the process of printing the pattern, the printer prints out the pre-set strips simultaneously on the edge of the printing medium. B. The detection head synchronously collects the detection pattern information printed by the inkjet head on the edge of the printing medium; C. Combines the collected detection pattern information with the pre-stored standard pattern information For comparison, if the two are consistent, the printer will continue to print; if they are inconsistent, the printer will interrupt the printing operation, and move the inkjet head out of the printing area to clean the inkjet head. After the cleaning process is completed, move the inkjet head Go back to the printing area and perform the printing operation again.

[0035] The above-mentioned automatic cleaning process of the inkjet head and the mutual switching of t...

Embodiment 2

[0042] As shown in Figure 4, in this embodiment, in step C, the cleaning of the inkjet head is powered by compressed air, and the ink is forced to flow out of the inkjet head for a period of time to clean the inkjet head. Wait for a while after completion before moving the inkjet head back to the print area.

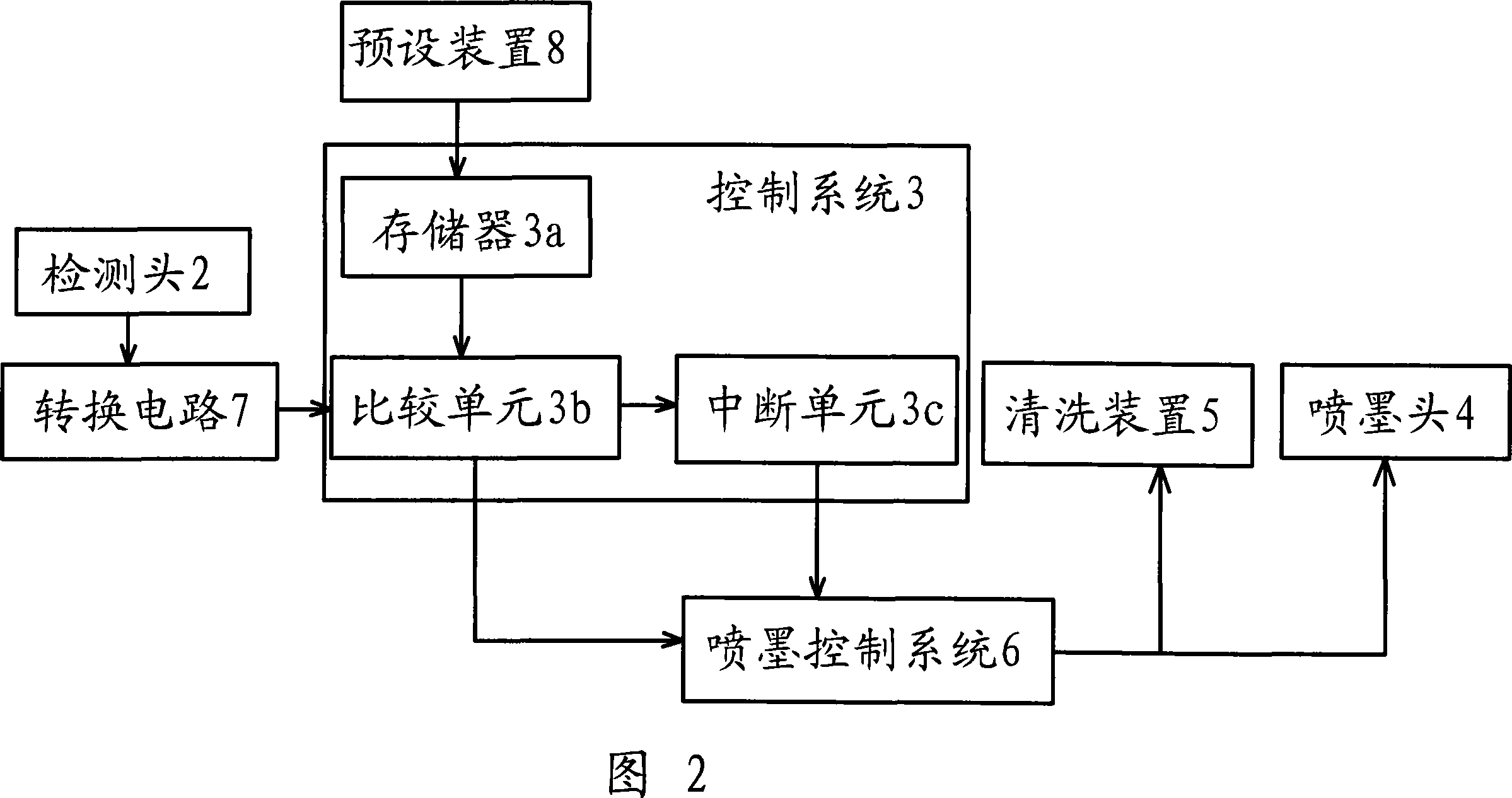

[0043] The interrupt unit 3c is connected to the inkjet head 4 through the cleaning device 5 . Since the inkjet head 4 is cleaned by flushing, in this embodiment, the interruption unit 3 c is connected to the cleaning device 5 , and the cleaning device 5 is connected to the inkjet head 4 through the inkjet control system 6 . When the inkjet head 4 stops printing operation, the ink control system 6 is controlled by the cleaning device 5 to flush the inkjet head 4 with ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com