Generating method and generating system for support of additive manufacturing

A technology of additive manufacturing and support system, applied in the field of additive manufacturing, can solve the problems of complex shape design of support structure, difficult to predict the damage of part model, and greater material consumption, so as to reduce printing cost, reduce damage, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

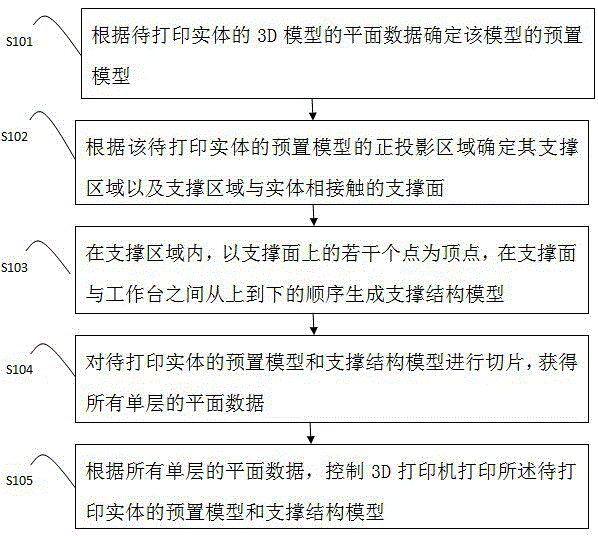

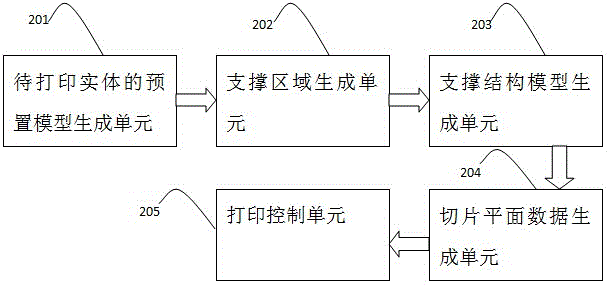

Method used

Image

Examples

Embodiment 1

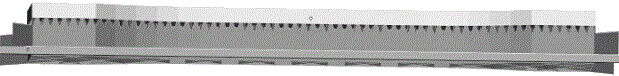

[0062] Such as Figure 4 , Figure 5 As shown, a schematic diagram and a perspective view of a support structure for additive manufacturing disclosed in Embodiment 1 of the present invention, the point support of the support model is tooth-shaped, and several vertices evenly arranged on the support surface cooperate with the point support, After the support structure model is added, slice the preset model of the solid structure and the support structure model, and then control the 3D printer to print the preset model of the solid structure and the support structure model. After the printing is completed, the support structure model is transferred from the solid structure model Remove below. This kind of support structure model is easy to peel off from the solid structure model, and has little damage to the solid structure model, which greatly improves the printing quality of the parts.

Embodiment 2

[0064] Such as Figure 6 As shown, the front view of a support structure for additive manufacturing disclosed in Embodiment 2 of the present invention, the bracket support of the support structure is similar to a rhombus, and it is closely and orderly arranged in the direction of the entity to be printed, and its point support is in the shape of a tooth , and several vertices on the support surface are matched with the point support. After the support structure model is added, slice the preset model of the solid structure and the support structure model, and then control the 3D printer to print the preset model and the support structure model of the solid structure. The supporting structure model, after the printing is completed, remove the supporting structure model from under the solid structure model. This kind of support structure can not only achieve less damage after being stripped from the solid structure model, but also has a hollow design, which has less loss of mater...

Embodiment 3

[0066] Such as Figure 7 As shown, the front view of a support structure for additive manufacturing disclosed in Example 3 of the present invention, its implementation is the same as in Example 2, the difference is that the bracket support of the support structure is in the shape of a rhombus, but it is not limited thereto. Its geometric shape can be three-dimensional or flat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com