Binocular vision three-dimensional morphology measurement method based on time and space constraints

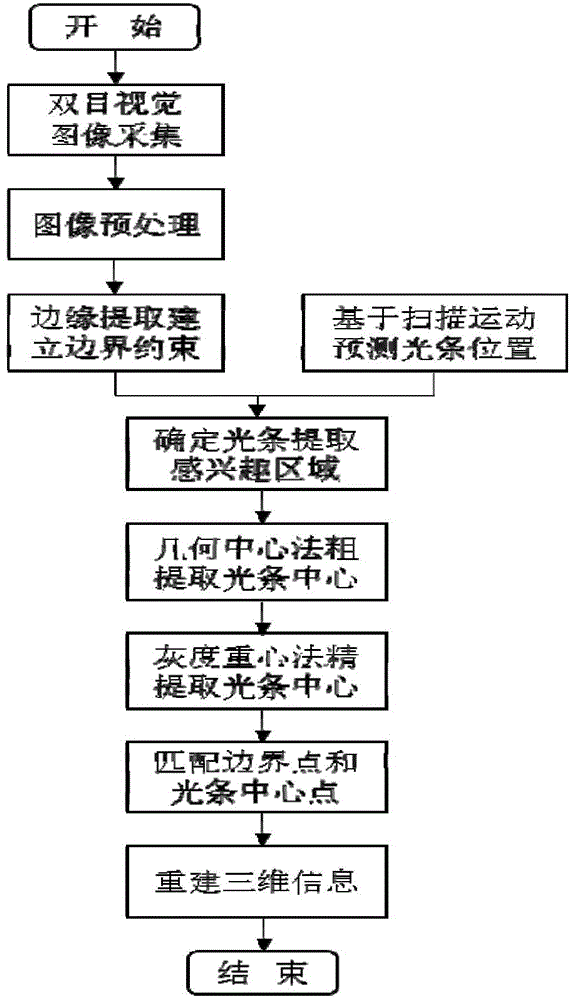

A technology for binocular vision measurement and three-dimensional topography, which is used in measurement devices, instruments, optical devices, etc., can solve the problems of incomplete edge information extraction and inaccurate measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

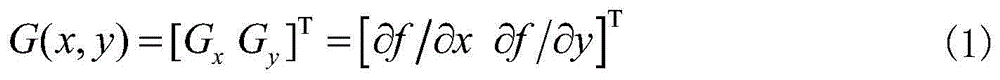

Method used

Image

Examples

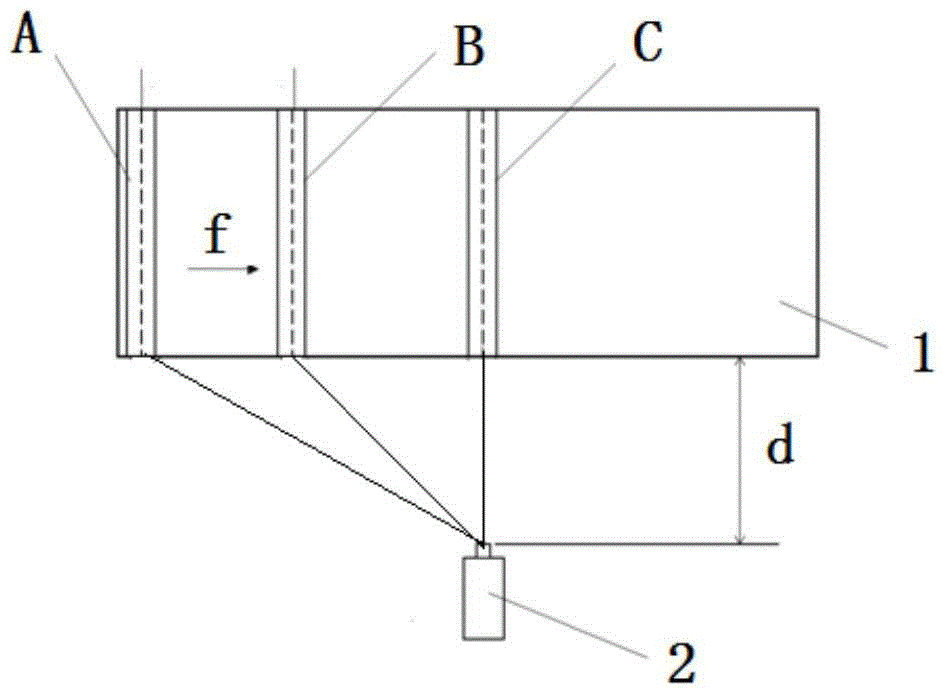

Embodiment 1

[0042] Embodiment 1, the present invention adopts two left and right cameras respectively equipped with wide-angle lenses to capture a light strip image. The camera model is viewworks VC-12MC-M / C 65 camera, resolution: 4096×3072, image sensor: CMOS, frame rate: full frame, maximum 64.3fps, weight: 420g. The wide-angle lens model is EF 16-35mm f / 2.8L II USM, the parameters are as follows, lens focal length: f=16-35, APS focal length: 25.5-52.5, aperture: F2.8, lens size: 82×106. The shooting conditions are as follows: the picture pixel is 4096×3072, the focal length of the lens is 17mm, the object distance is 750mm, and the field of view is about 800mm×800mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com