Morphology registration analysis-based method for detecting precision of precise main shaft rotation

A rotary precision and precision technology, applied in the direction of measuring devices, measuring/indicating equipment, instruments, etc., can solve problems such as complex test systems and test processes, expensive standard outer circle contours, etc., and achieve the effect of simple measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

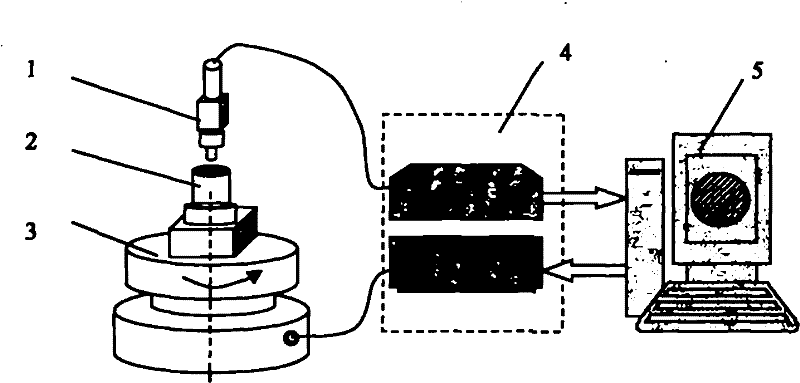

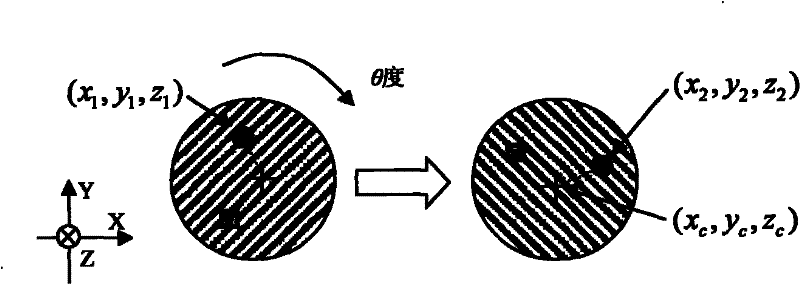

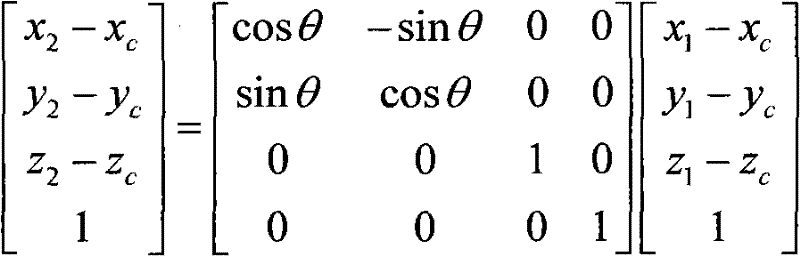

[0012] For a preferred embodiment of the present invention, see figure 1 with figure 2 , first, the surface sample 2 is installed on the precision spindle 3 to be measured, and the position of the surface sample 2 is adjusted so that it is near the center of rotation of the precision spindle 3 to be measured; two, the surface microtopography measurement sensor 1 is adjusted relative to the surface sample 2, so that the measurement range of the surface micro-topography measurement sensor 1 covers the center of rotation position when the surface sample 2 rotates with the precision spindle 3 to be measured; 3. The control system 4 controls the precision spindle 3 to be measured to a certain angular position ( Such as to the 0° position or the origin position), a surface topography map is measured by the surface micro-topography measurement sensor 1; the control system 4 controls the precision spindle 3 to be measured to an angle θ position (which can be uniformly distributed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com