Three-dimensional measurement method suitable for bright surface

A three-dimensional measurement and bright technology, applied in the field of optical measurement, can solve the problems of coating thickness and uniformity measurement error, spraying and cleaning coating to reduce measurement efficiency, increase the complexity of hardware system, etc. Intervention, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The main steps of the three-dimensional measurement method applicable to bright surfaces of the present invention can be briefly summarized as follows:

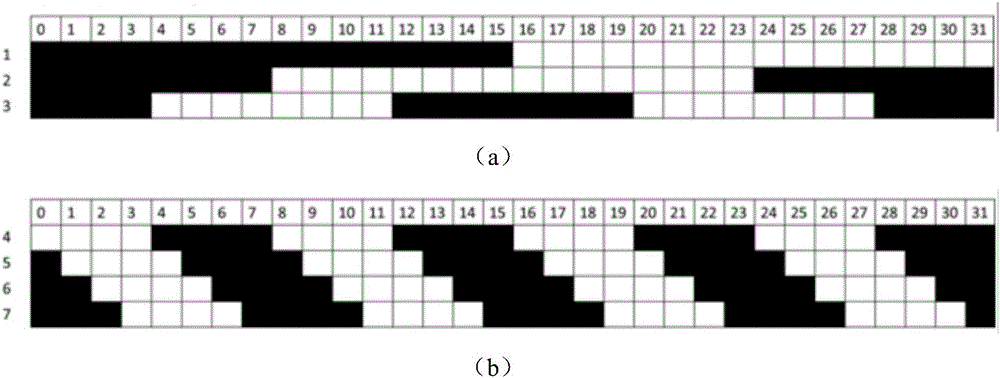

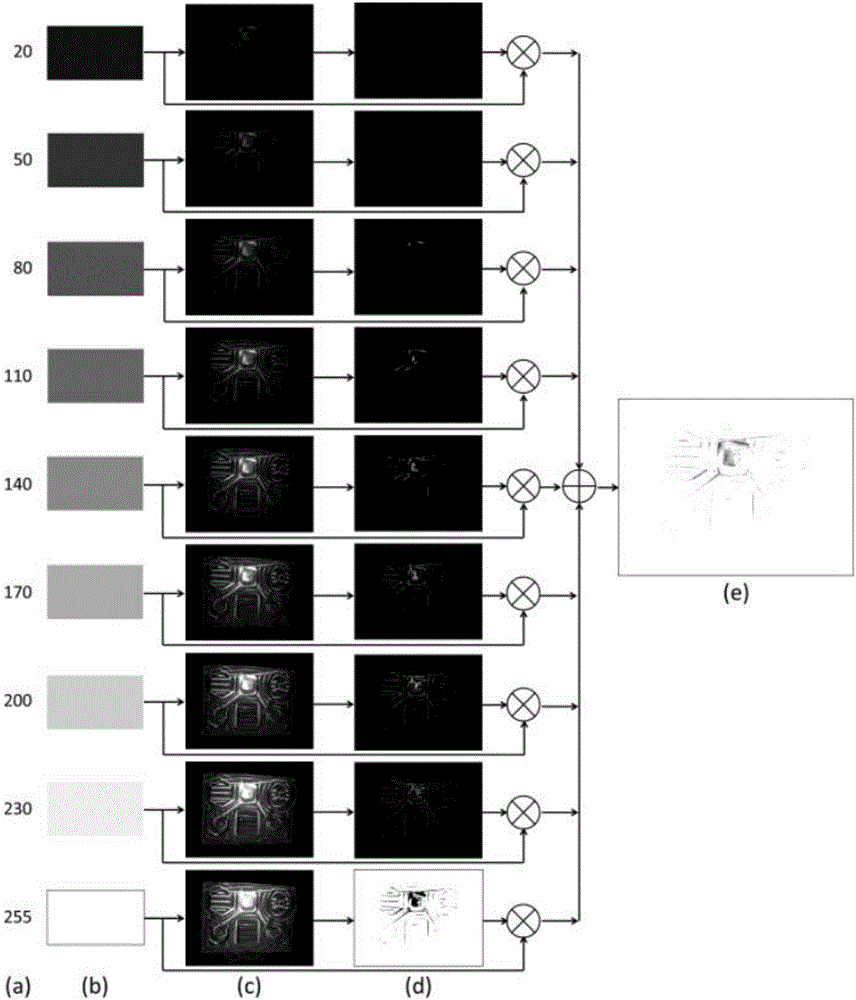

[0045] Step 1: Project a series of uniform light patterns with different gray values to the measured object, and take corresponding uniform light images of the measured object.

[0046] Step 2: Calculate the optimal projected gray value of each pixel to generate the optimal gray value fringe pattern.

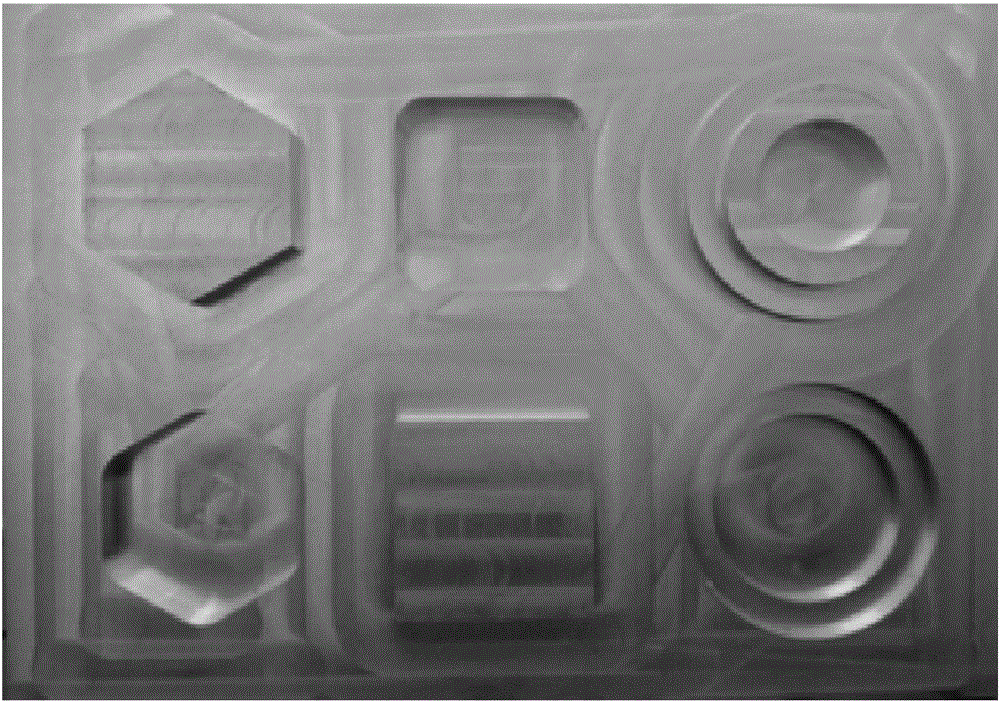

[0047] Step 3: Project the optimal gray value fringe pattern to the measured object, and correspondingly capture the optimal gray value fringe image of the measured object.

[0048] Step 4: Decoding the optimal gray value fringe image, solving the three-dimensional coordinates and surface reconstruction, and recovering the three-dimensional shape of the measured object.

[0049] Specifically, the three-dimensional measurement method applicable to bright surfaces of the present invention includes the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com