Device and method for detecting uniformity of infrared optimal material

A technology of infrared optical materials and detection devices, which is applied in the direction of optical testing of flaws/defects, analysis of materials, instruments, etc., to achieve better material uniformity and accurate evaluation of material uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The double-circumferential spring synchronizer of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

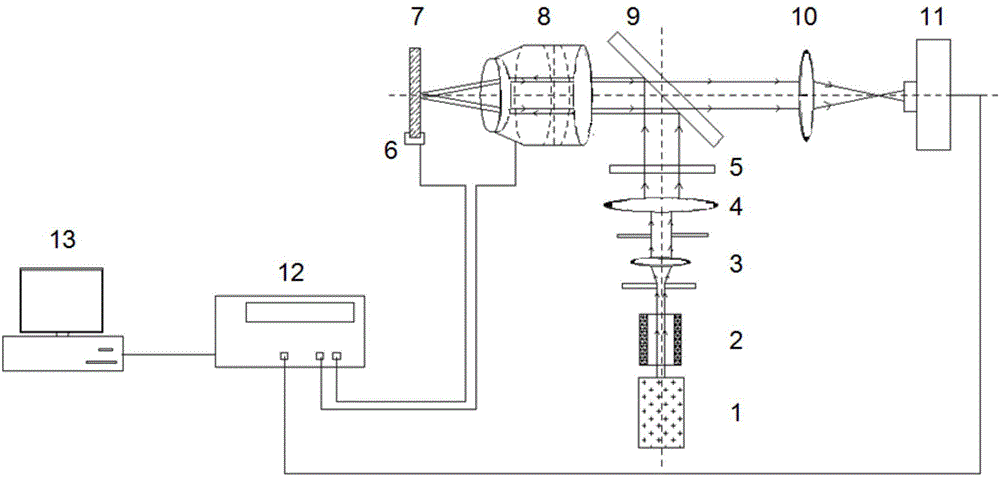

[0034]The technical solution adopted by the present invention to solve the above-mentioned technical problems is: a method and device for detecting the uniformity of visible light opaque infrared optical materials, which is characterized in that it includes an infrared light source 1, a stray light shielding tube 2, a collimating component 3, and a beam expanding component 4. Optical filter group 5, infrared beam splitter 9, infrared zoom lens 8, two-dimensional precision mobile stage 6, condenser lens 10, infrared sensor 11, signal acquisition and controller 12, computer 13.

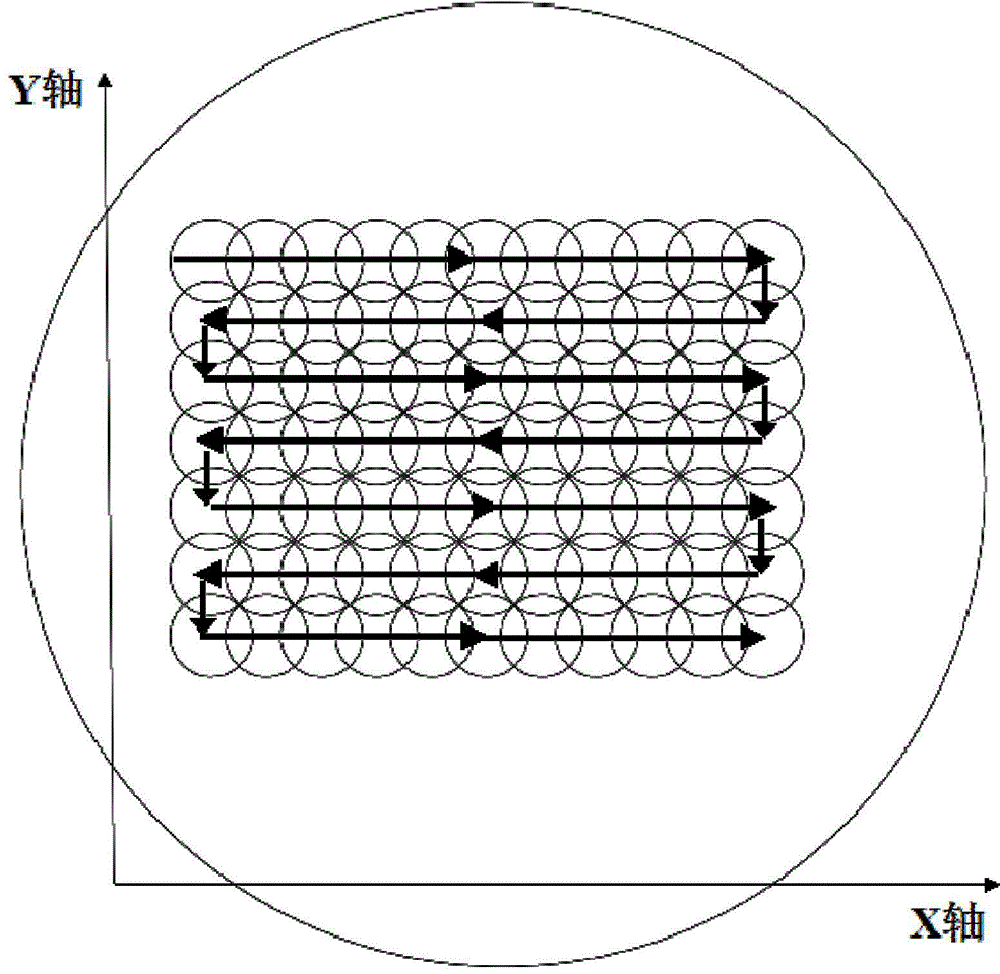

[0035] Infrared light source 1, stray light shielding tube 2, collimating part 3, beam expanding part 4, and filter group 5 are arranged in sequence to form an infrared uniform light source generating device, in which each part s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com