Al-Ga-In-Sn-Zn alloy as well as preparation method and application thereof

An alloy and metal technology, applied in the field of Al-Ga-In-Sn-Zn alloy and its preparation, can solve the problems of difficulty in meeting the power requirements of automobiles, low hydrogen production rate and hydrogen production rate of the alloy, etc. Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0032] The preparation of embodiment 1-4Al-Ga-In-Sn-Zn alloy

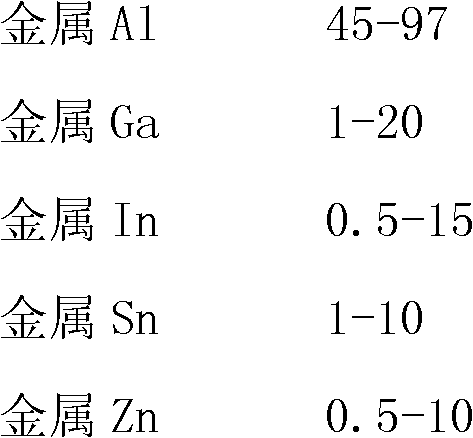

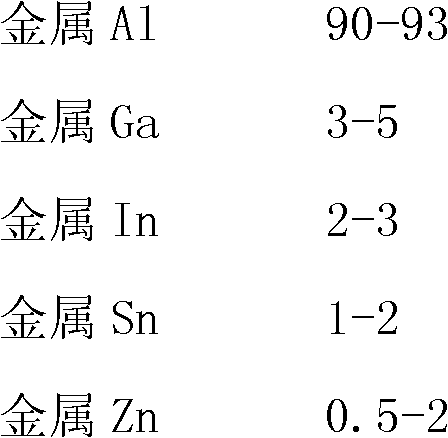

[0033] (1) The alloy composition is shown in Table 1:

[0034] The mass percent (wt%) of the aluminum alloy constituent elements of Table 1 Example 1-4

[0035]

[0036] (2) Preparation process:

[0037] Raw materials are various high-purity powders, Al, In, Sn, Zn particle diameters are all 99%, Ga is bulk material, added in liquid state (melting point: 29.76), purity >99%. Under the protection of argon, use a planetary ball mill for ball milling, and the ball milling parameters are as follows: the ball-to-material ratio is 5:1; the ball milling time is 12 hours; the rotational speed is 500 r / min.

[0038] (3) Hydrogen production rate index:

[0039] The aluminum alloys prepared in Examples 1-4 react violently in ice water and generate a large amount of hydrogen. The hydrogen production rate is shown in Table 2.

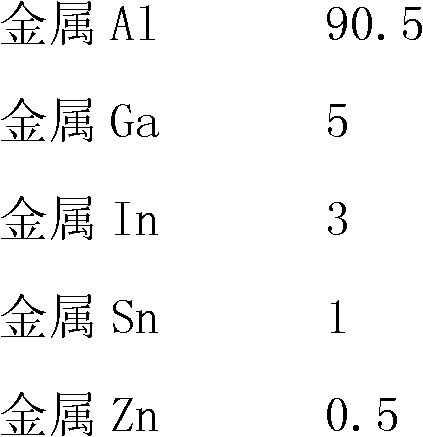

[0040] The hydrogen production rate of table 2 embodiment 1-4 aluminum alloy

[0041]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com