Preparation method of fermented aggregate-containing crispy pastry

A technology for crispy cakes and aggregates, which is applied in the processing of dough, baking, and baked goods, etc., can solve the problems of waste of resources, environmental pollution of livestock and poultry bones, and low utilization rate of livestock and poultry bones, and achieve the effect of ensuring crispness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

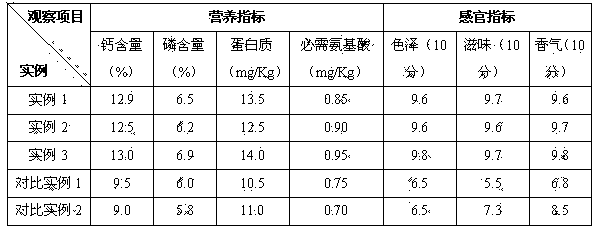

Examples

Embodiment 1

[0026] (1) Take 10Kg of chicken bones, 12Kg of beef bones, and 13Kg of sheep bones. After crushing them, cook them for 30 minutes at a temperature of 146°C and a pressure of 0.3MPa. After cooling, the mass ratio of bone to water is 1:1. Add water and carry out colloidal grinding, and then add compound enzyme according to the weight of the bone. The amount of enzyme added is 450,000 U / kg of cellulase, 1,000 U / kg of hemicellulase, and 200,000 U / kg of active protease. Mix the enzyme and bone pulp evenly, keep warm at 35°C for 2 hours, and control the ambient humidity at 80%-95%;

[0027] (2) After cooling the slurry in step (1), add according to the weight ratio (mL / Kg): 10 mL of Lactobacillus plantarum, 5 mL of Lactobacillus plantarum subsp. Ferment for 3 days, turn the material during the fermentation, and control the ambient humidity at 65%-88%, to obtain fermented bone pulp;

[0028] (3) Weigh 10 parts of bone pulp, 85 parts of flour, 1 part of NaCl, 0.25 parts of monosodi...

Embodiment 2

[0033] (1) Take 15Kg of chicken bones, 14Kg of beef bones, and 15Kg of sheep bones. After crushing them, cook them for 35 minutes at a temperature of 160°C and a pressure of 0.5MPa. After cooling, the mass ratio of bone to water is 1:1.5 Add water and carry out colloidal grinding, and then add compound enzyme according to the weight of the bone. The amount of enzyme added is 900,000 U / kg of cellulase, 2,000 U / kg of hemicellulase, and 300,000 U / kg of active protease. Mix the enzyme and bone pulp evenly, keep warm at 40°C for 5 hours, and control the ambient humidity at 80%-95%;

[0034] (2) After cooling the slurry in step (1), add according to the weight ratio (mL / Kg): 15mL of Lactobacillus plantarum, 8mL of Lactobacillus plantarum subsp. Ferment for 5 days, turn the material during the fermentation, and control the ambient humidity at 65%-88%, to obtain fermented bone pulp;

[0035] (3) Weigh 15 parts of bone pulp, 90 parts of flour, 2.5 parts of NaCl, 0.45 parts of monoso...

Embodiment 3

[0040](1) Take 13Kg of chicken bones, 13Kg of beef bones, and 14Kg of sheep bones, crush them, and cook them for 33 minutes at a temperature of 150°C and a pressure of 0.4MPa. After cooling, the mass ratio of bone to water is 1:1.2 Add water and carry out colloidal grinding, and then add compound enzyme according to the weight of the bone. The amount of enzyme added is 670,000 U / kg of cellulase, 1,500 U / kg of hemicellulase, and 250,000 U / kg of active protease. Mix the enzyme and the bone pulp evenly, keep it warm at 38°C for 3.5 hours, and control the ambient humidity at 80%-95%;

[0041] (2) After cooling the pulp in step (1), add according to the weight ratio (mL / Kg): 13mL of Lactobacillus plantarum, 7mL of Lactobacillus plantarum subsp. Ferment for 4 days, turn material during the fermentation, and control the ambient humidity at 65%-88%, to obtain fermented bone pulp;

[0042] (3) Add by weight: 13% bone pulp, 87% flour, 2% NaCl, 0.3% monosodium glutamate, 0.25% soda po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com