Preparation method for polyacrylamide-acrylic acid-VDT physical-crosslinking high-strength hydrogel

A polyacrylamide and physical cross-linking technology, applied in the field of polymer materials, can solve the problems of less than 1MPa tensile strength, difficult to stabilize hydrogel properties, low hydrogel strength, etc., and achieves low production cost and high toughness molecules. Adsorption function, the effect of excellent molecular adsorption function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

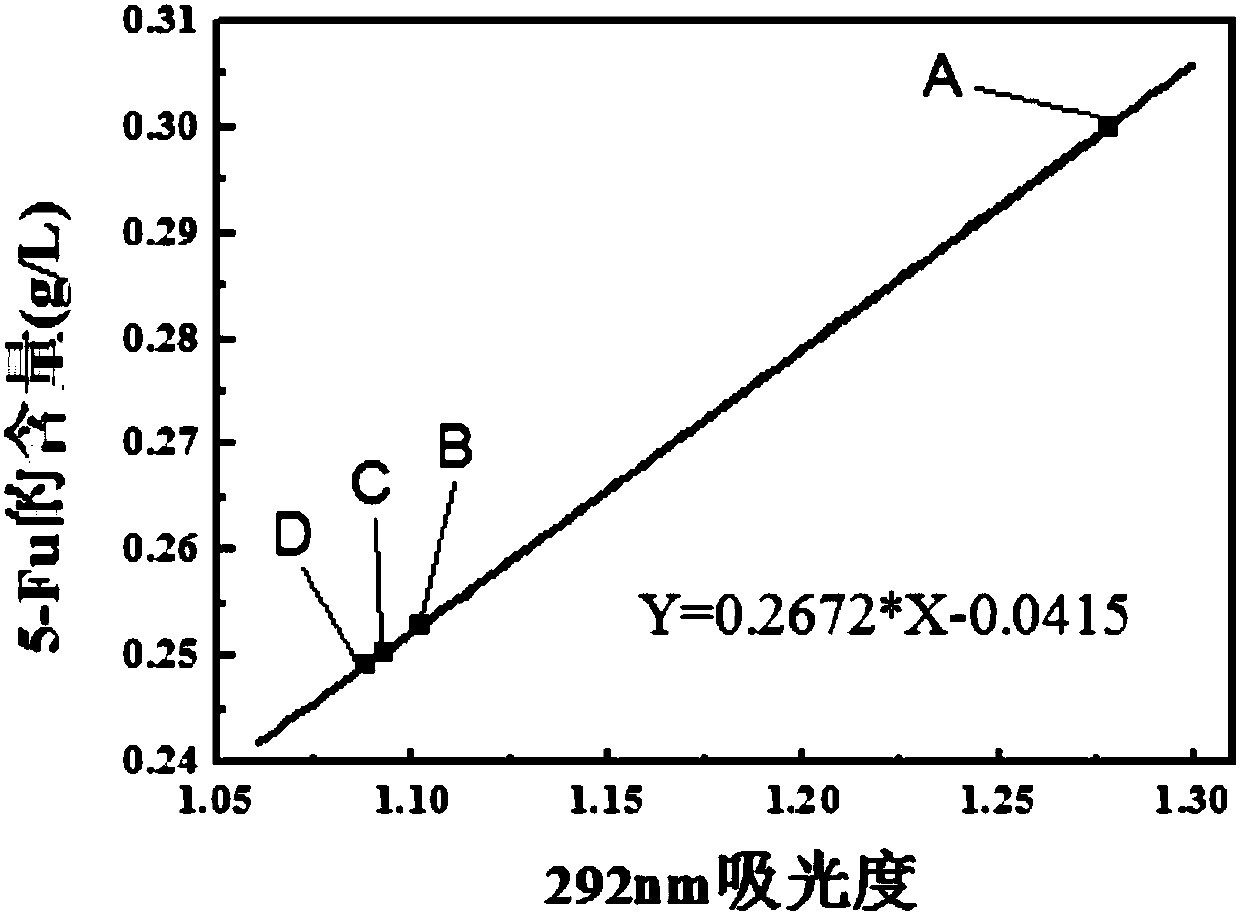

Image

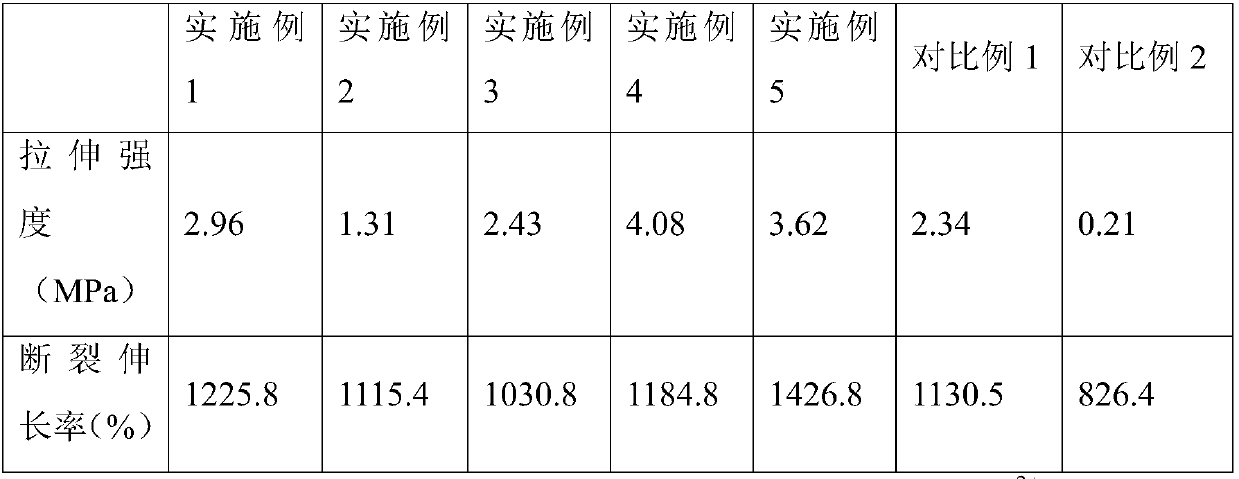

Examples

Embodiment 1

[0033] 1) Weigh 0.05g of VDT into a three-necked flask, add 5ml of dimethyl sulfoxide, stir and dissolve at room temperature, accounting for 0.85wt% of the total of VDT, acrylic acid, and acrylamide;

[0034] 2) Weigh 0.757g of acrylic acid, 4.975g of acrylamide, and 0.008g of ammonium persulfate in a beaker at room temperature, add 5ml of dimethyl sulfoxide to prepare a mixed solution; the concentration of acrylic acid is 1.05mol / L, and the concentration of propylene The amide concentration is 7.0mol / L, and the concentration of ammonium persulfate is 0.0035mol / L;

[0035] 3) Mix the mixed solution in step 2) and the VDT solution in step 1) in an ice-water bath at 0°C and stir evenly. After one hour, add 50 μL of tetramethylethylenediamine to obtain acrylamide-acrylic acid-VDT mixture solution;

[0036] 4) Pour the acrylamide-acrylic acid-VDT mixed solution obtained in step 3) into a glass mold with a polyester film inside, place it in a hot water bath environment at 40°C, an...

Embodiment 2

[0041] 1) Weigh 0.1g of VDT into a three-necked flask, add 5ml of dimethyl sulfoxide, stir and dissolve at room temperature, accounting for 1.75wt% of the total of VDT, acrylic acid, and acrylamide;

[0042] 2) Weigh 0.324g of acrylic acid, 2.132g of acrylamide, and 0.010g of ammonium persulfate in a beaker at room temperature, add 5ml of dimethyl sulfoxide to prepare a mixed solution; the concentration of acrylic acid is 0.45mol / L, and the concentration of propylene The amide concentration is 5.0mol / L, and the concentration of ammonium persulfate is 0.0044mol / L;

[0043] 3) Mix the mixed solution in step 2) and the VDT solution in step 1) in an ice-water bath at 0°C and stir evenly. After one hour, add 40 μL of tetramethylethylenediamine to obtain acrylamide-acrylic acid-VDT mixture solution;

[0044] 4) Pour the acrylamide-acrylic acid-VDT mixed solution obtained in step 3) into a glass mold with a polyester film inside, place it in a hot water bath environment at 50°C, and...

Embodiment 3

[0049] 1) Weigh 0.2g of VDT into a three-necked flask, add 5ml of dimethyl sulfoxide, stir and dissolve at room temperature, accounting for 3.50wt% of the total of VDT, acrylic acid, and acrylamide;

[0050] 2) Weigh 0.757g of acrylic acid, 4.975g of acrylamide, and 0.016g of ammonium persulfate in a beaker at room temperature, add 5.0ml of dimethyl sulfoxide to prepare a mixed solution; the concentration of acrylic acid is 1.05mol / L, The concentration of acrylamide is 7mol / L, and the concentration of ammonium persulfate is 0.0070mol / L;

[0051] 3) Mix the mixed solution in step 2) and the VDT solution in step 1) in an ice-water bath at 0°C and stir evenly. After one hour, add 60 μL of tetramethylethylenediamine to obtain acrylamide-acrylic acid-VDT mixture solution;

[0052] 4) Pour the acrylamide-acrylic acid-VDT mixed solution obtained in step 3) into a glass mold with a polyester film inside, place it in a hot water bath environment at 50°C, and react for 12 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com