Fracture strength testing device and method of ribbon for automobile safety belt

A technology of breaking strength and testing device, which is applied in the direction of measuring device, strength characteristics, and the use of stable tension/pressure testing material strength, etc., can solve problems such as webbing slipping, and achieve slipping problems, high testing accuracy, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

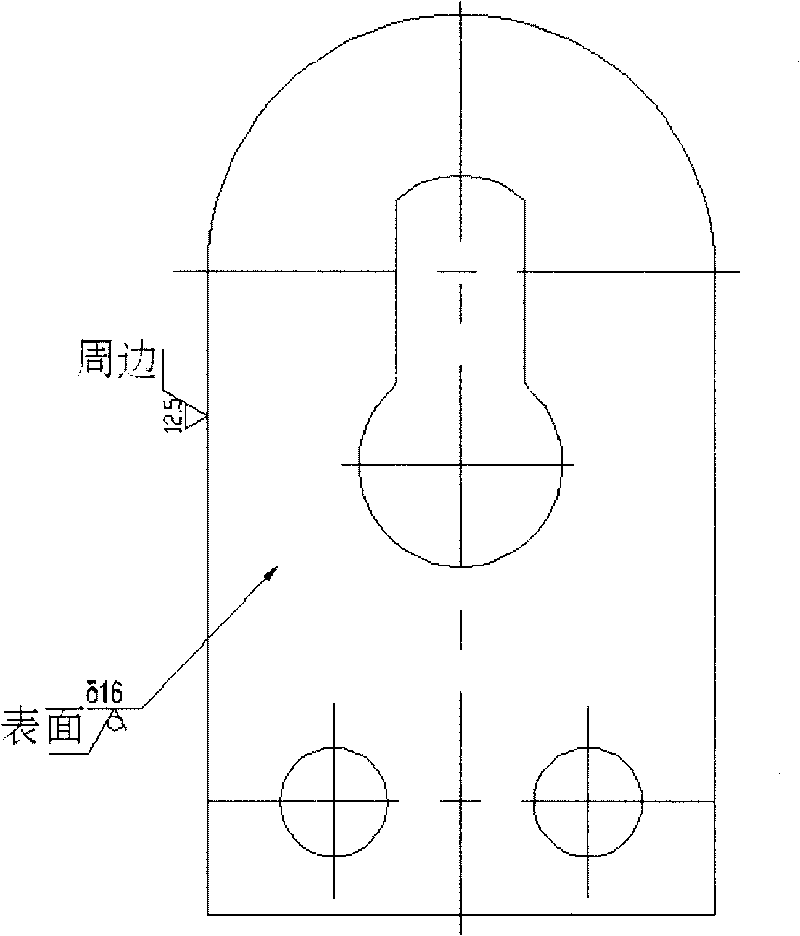

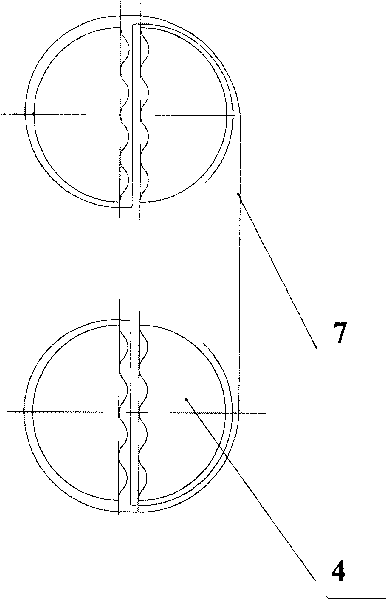

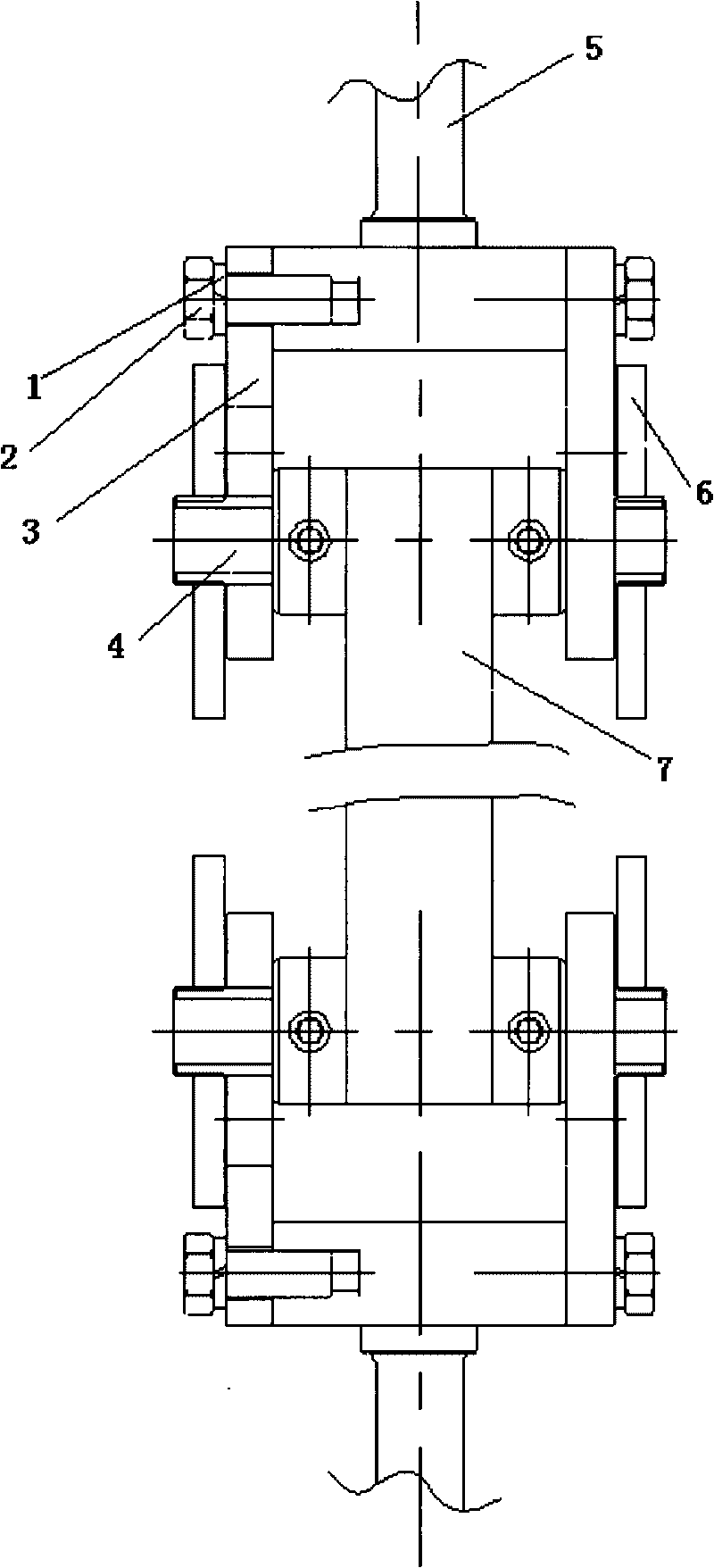

[0036] This embodiment relates to a device and method for testing the breaking strength of webbing used for safety belts. The power part of this program is a common universal testing machine in the laboratory. Two pieces of this device form a group. The connecting end is made according to the interface of the universal testing machine. The device is mainly composed of a load-bearing frame and a locking part that acts as a locking webbing. The buckle clamping platform plays the function of transmitting load and supporting and locking the buckle. The buckle is composed of two parts with a wavy contact surface, and plays the function of locking the webbing. The webbing is wrapped around the buckle in a specific way to ensure that it does not slip during the test. The breaking strength valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com