Centrifugal switch suitable for motor driving

A centrifugal switch, motor-driven technology, used in electrical switches, motor generators/starters, circuits, etc., can solve the problems of unstable opening and closing of contacts, large impact force, easy damage, etc., to improve convenience, The effect of improving the service life and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

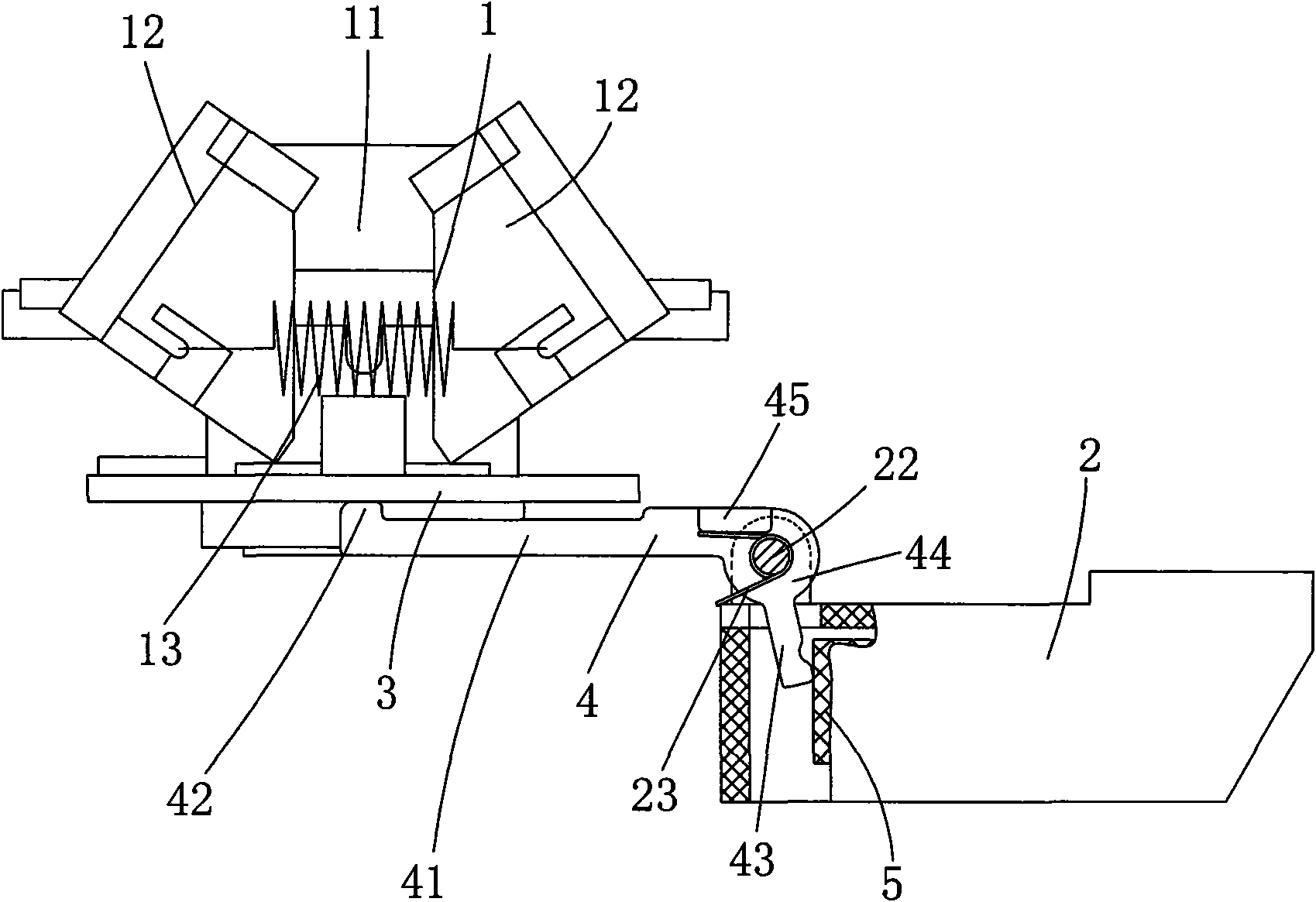

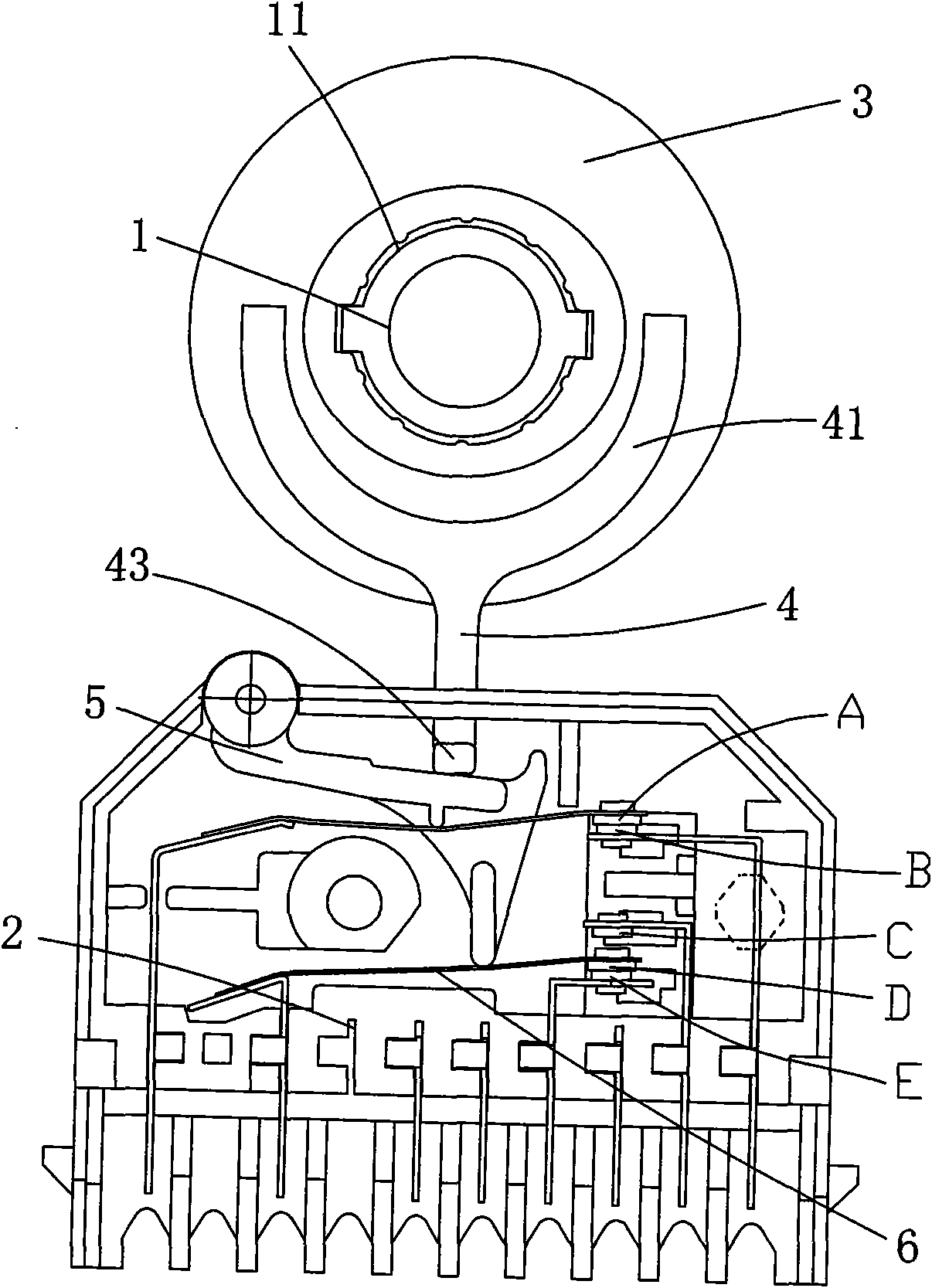

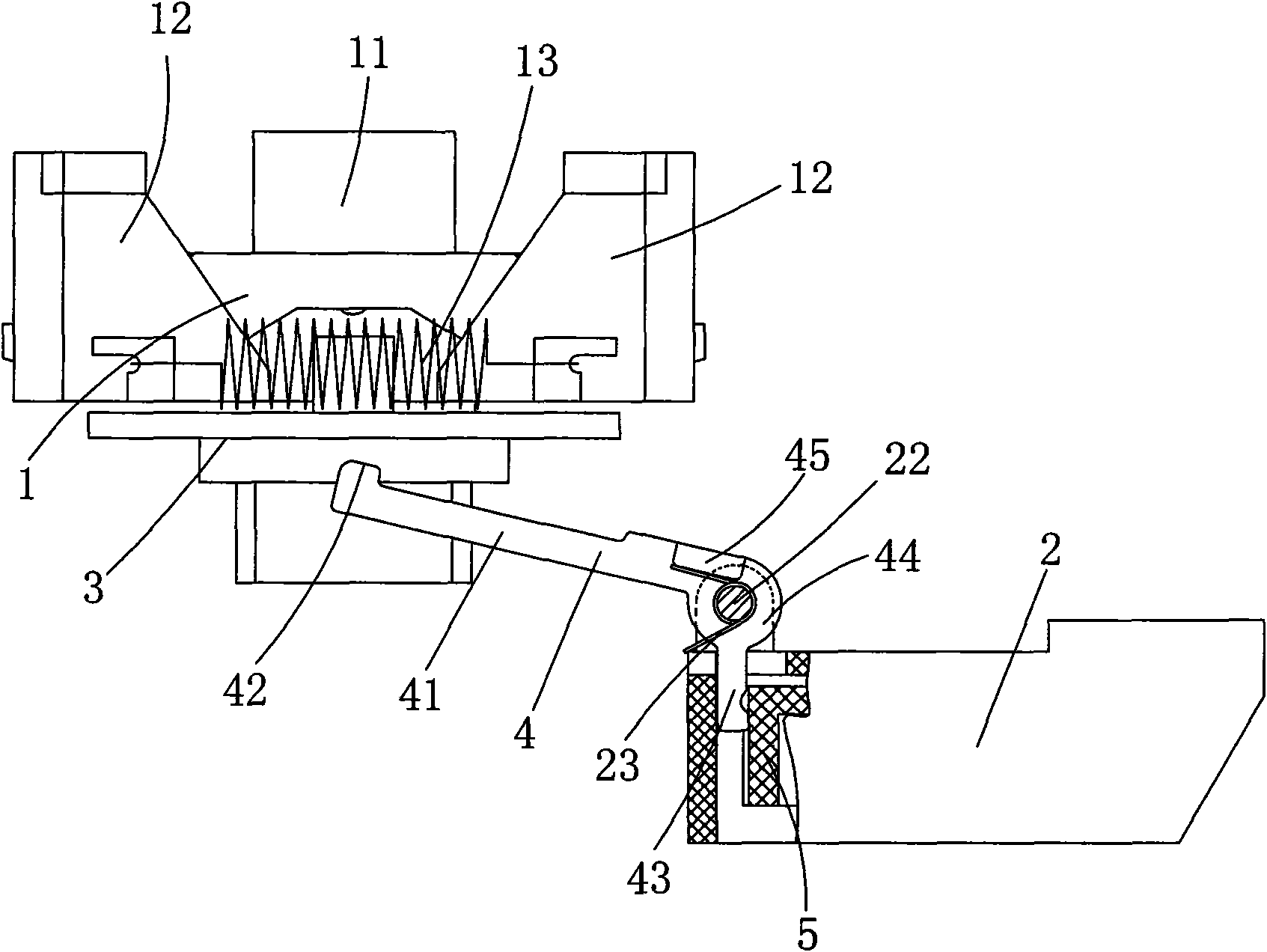

[0023] Such as figure 1 , figure 2 As shown, a centrifugal switch suitable for motor drive consists of two parts: the centrifuge 1 and the wire box body 2 . The centrifuge 1 is installed on the rotating shaft of the motor, and the wire box body 2 is installed on the end cover of the motor.

[0024] The structure of a general centrifuge 1 includes a drive seat 11 that is plugged and matched with the motor shaft. The upper cross arms of the drive seat 11 are symmetrically hung with counterweights 12, and tension springs 13 are hung between the counterweights 12. The tension springs 13 control The counterweight body 12 leans inward against the cage; and the bottom side of the counterweight body 12 is hooked to both sides of the sliding sleeve 3; as the rotation speed of the motor increases, the counterweight body 12 overcomes the centrifugal force of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com