Single-phase AC motor starting method

A single-phase AC motor and starting method technology, which is applied to the starter of a single single-phase induction motor, motor generator/starter, etc., can solve the problems of affecting the service life of the motor, potential safety hazards of the motor, and high production costs, and achieve extension Long service life, improved reliability, and large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

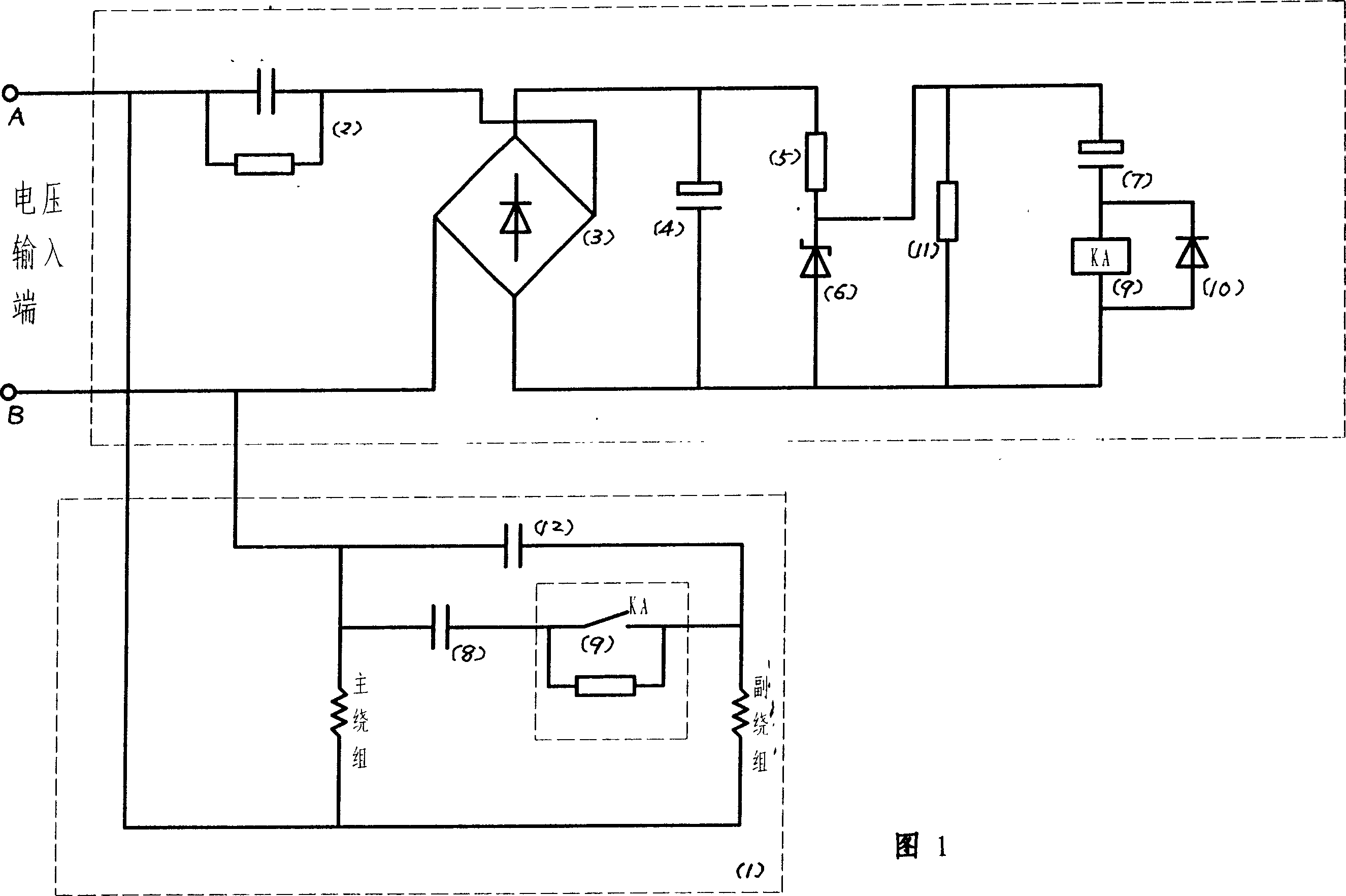

[0020] Example 1. A starting method for a single-phase AC motor, the designed circuit is shown in Figure 1. The method connects a circuit together with the winding circuit (1) of the motor to the single-phase AC mains in parallel, comprising the following steps:

[0021] (1) Design a resistor-capacitor parallel circuit (2) connected to one end A of the AC mains power to step down the AC mains power;

[0022] (2) Install a rectifier circuit (3) between the output terminal of the resistor-capacitor parallel circuit (2) and the other end B of the AC mains to rectify the AC to DC;

[0023] (3) A filter capacitor (4) is connected in parallel at the output end of the rectification circuit (3) to make the DC output more stable;

[0024] (4) On the filter capacitor (4), the voltage stabilizing circuit connected in parallel by the resistor (5) and the voltage regulator tube (6) is connected in series to stabilize the voltage;

[0025] (5) connect the series circuit of the coil of la...

Embodiment 2

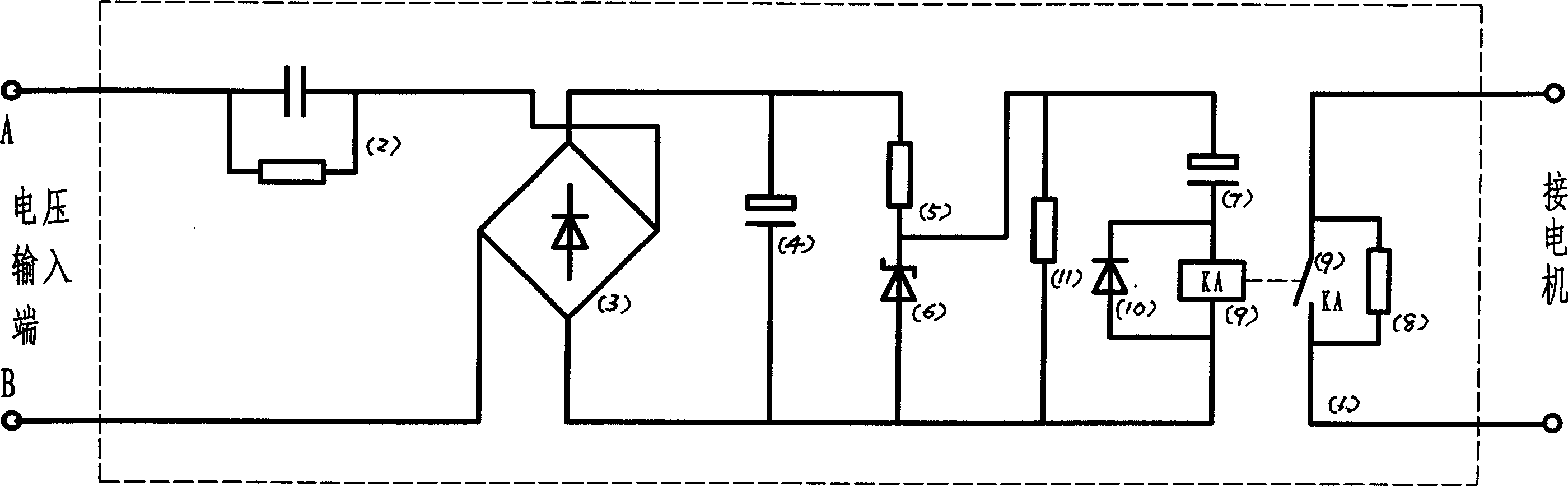

[0028] Example 2. A method for starting a single-phase AC motor, such as figure 2 shown. In the method, a circuit and the winding circuit (1) of the motor are connected in parallel to the single-phase AC commercial power. A normally open contact of its relay (9) and the starting element are connected in the winding circuit (1) of the motor.

[0029] Embodiments 1 and 2 avoid using a centrifugal switch, the circuit is simple, the production cost can be significantly reduced, and the reliability can be improved. It can greatly improve the starting performance and effectively prolong the service life of the motor. Its production cost can be reduced to about one-third of the past. It can be widely used in the starting of single-phase AC motors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com