Space wedge type centrifugal clutch capable of rapidly acting, dual clutch transmission with clutch and operation method thereof

A centrifugal clutch and fast action technology, applied in the direction of automatic clutches, clutches, components with teeth, etc., can solve the problems of high hydraulic automatic transmission production cost, high energy consumption for shifting, complex structure, etc., and achieve sensitive and fast action response , high transmission efficiency and high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

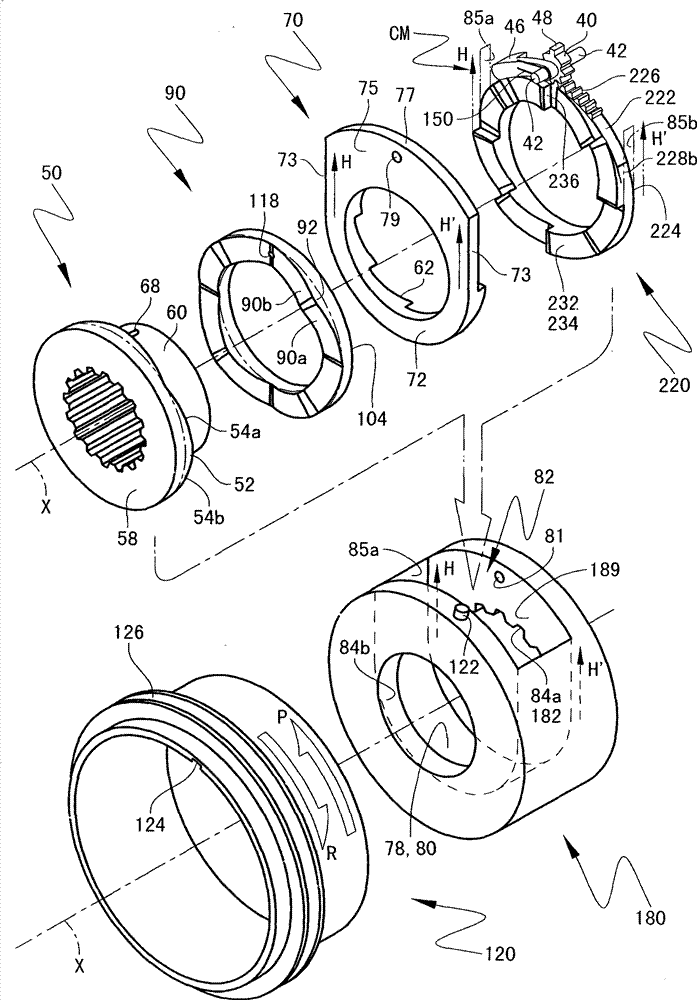

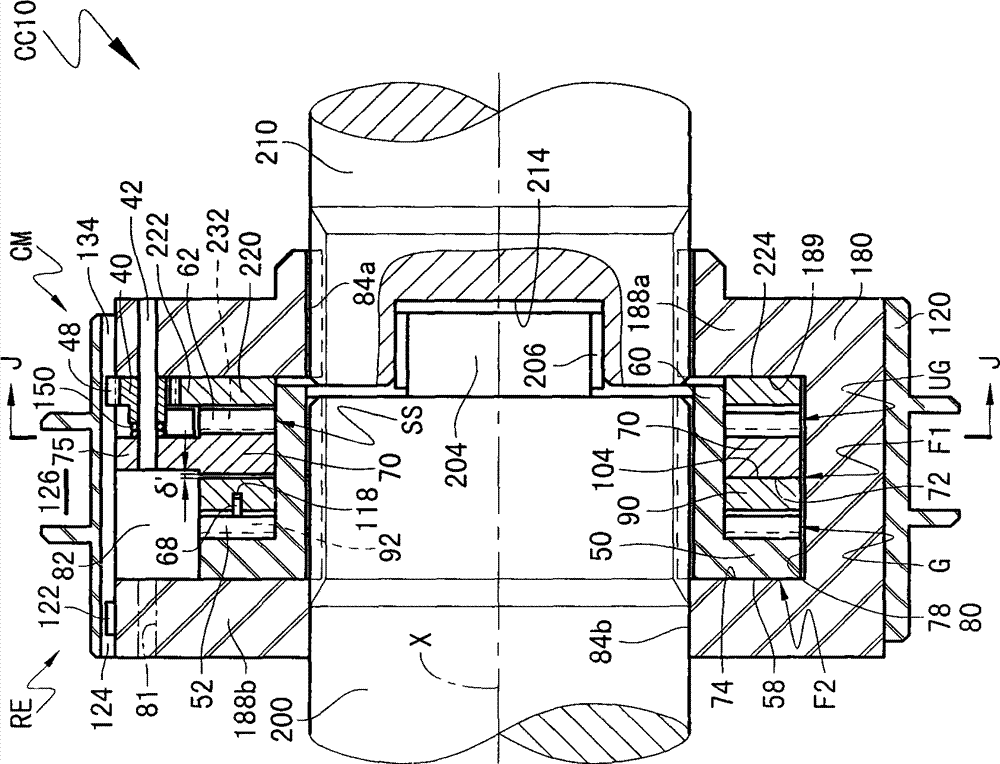

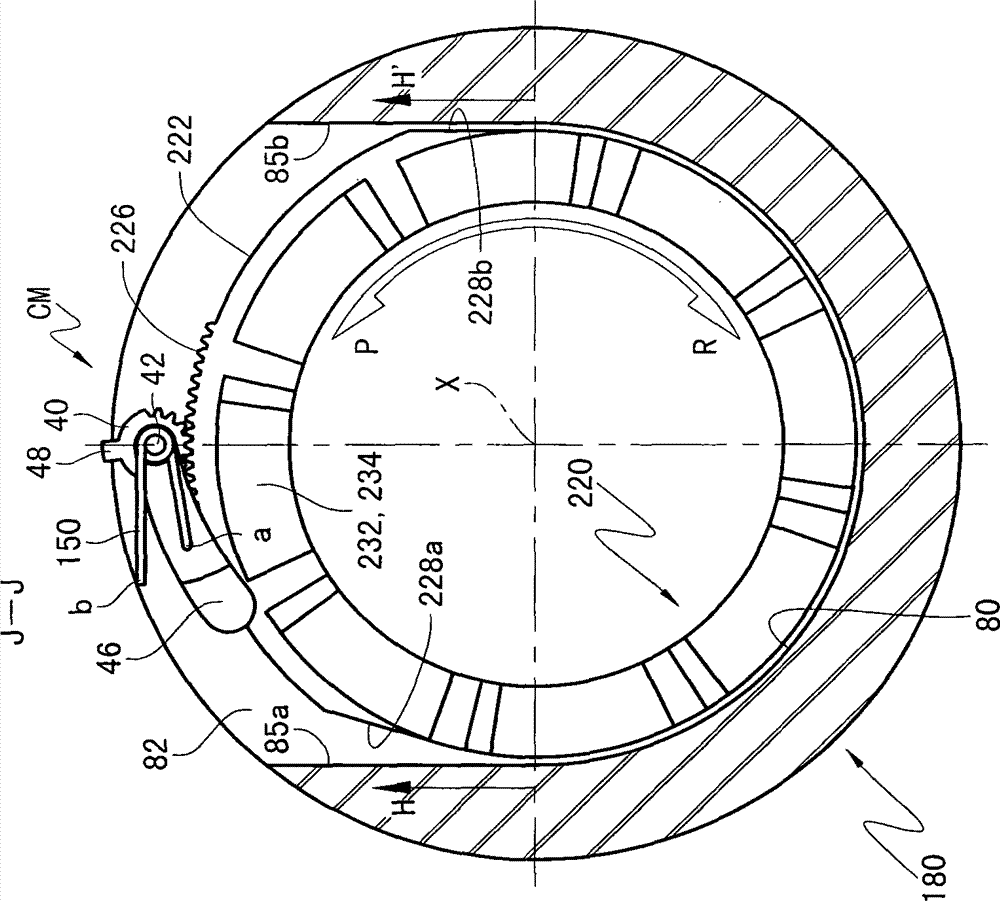

[0044] Embodiment 1: Single-switch type fast-acting spatial wedging centrifugal clutch CC10

[0045] Figure 1~3 Shown is a first embodiment of the present invention, which includes a force limiting element 180 formed around the axis X and having an axial force sealing function. The force limiting element 180 is preferably an annular pocket-shaped member, and the axial middle part of the inner peripheral surface 84 formed around the axis X is coaxially provided with a disc-shaped annular circumferential groove that is preferably planar. 78. The inner surface of about half of the circumferential groove 78 preferably extends to the outer peripheral surface of the force limiting element 180 along two mutually parallel tangential directions H and H′, and forms a rectangular inlet 82 with equal cross-section. The radially inner surface 80 of the circumferential groove 78 thus extends into a non-closed inner radial surface with a U-shaped cross-sectional shape and forms two mutual...

Embodiment 2

[0090] Embodiment 2: Multi-switching type fast-acting spatial wedging centrifugal clutch CC20

[0091] Such as Figure 5-6 As shown, the second embodiment is a direct modification of the first embodiment.

[0092] First, in order to realize small-diameter wheel-shaft transmission, the second shaft 210 is eliminated, and the gear teeth 168 are directly formed on the outer peripheral surface of the end flange 187 extending from the outer end surface of the disk-shaped end portion 188b.

[0093] Secondly, in order to obtain multi-switching capability, the centrifugal actuation mechanism CM is modified into a pin-slot guide rod mechanism. Wherein, all rod-shaped bases of the guide rod 20 are slidably disposed in the radial reference straight guide groove 22 on the support end surface 189 , and optimally do not contact the support end surface 224 . The outer peripheral surface of the arc-shaped block 26 located at the radially outer end of the guide rod 20 is provided with a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com