Rotatable master control module of brushless synchronous motor

A main control module and synchronous motor technology, applied in the direction of the starting device, etc., can solve the problems of high requirements for the installation and control of discrete components, high maintenance rate of mechanical centrifugal switches, and the impact of discrete components, so as to achieve compact structure, solve the destructive effect, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

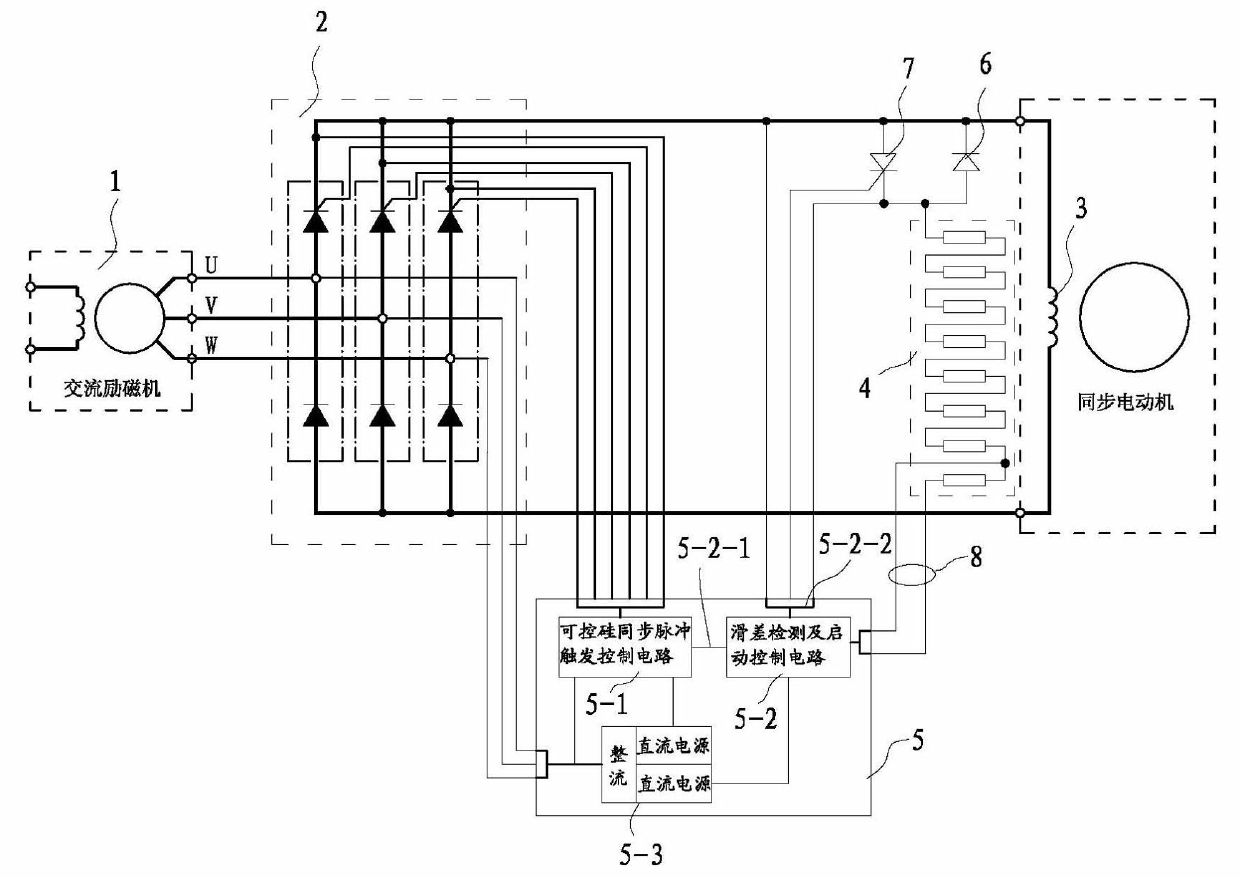

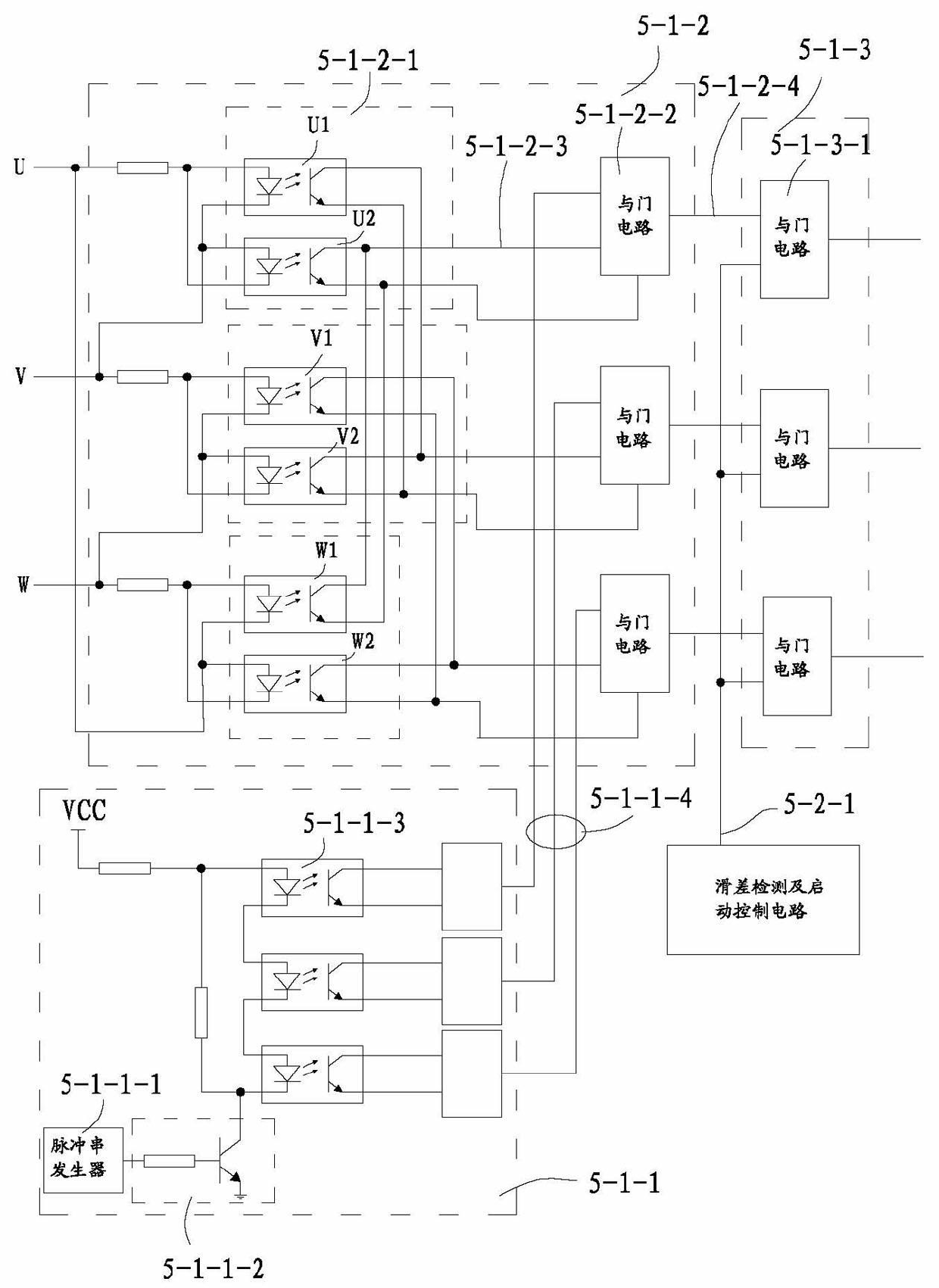

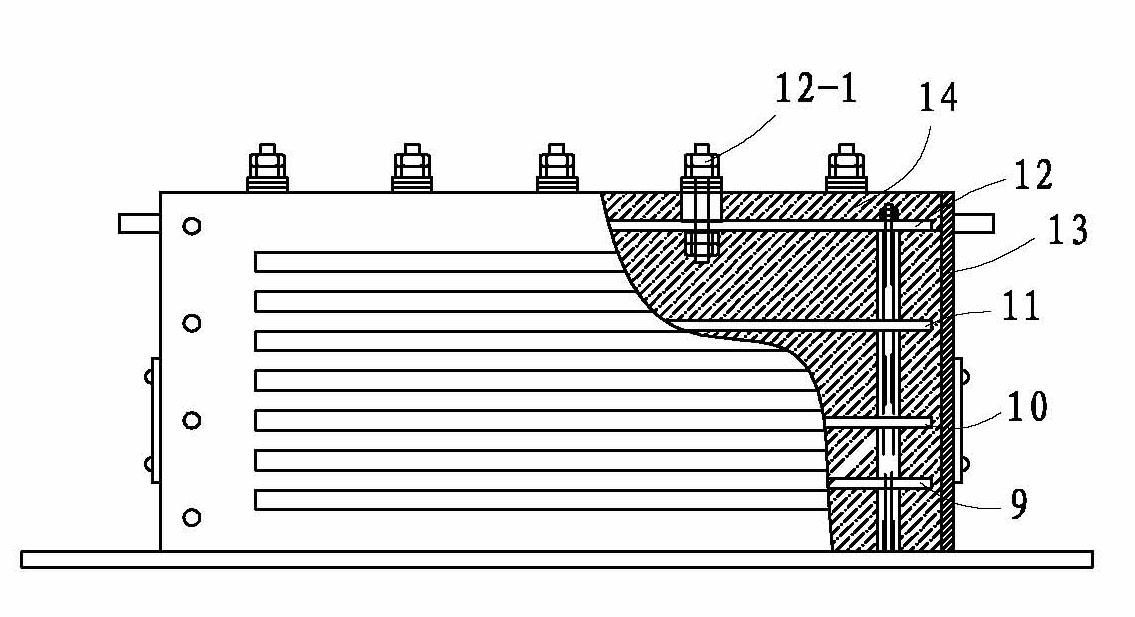

[0013] An embodiment of a brushless synchronous motor rotating main control module, see figure 1 , figure 2 with image 3 , the module includes an AC exciter 1, a silicon controlled rectifier 2, an armature excitation coil 3 in a synchronous motor, a starting resistor 4 and a control logic circuit 5; the silicon controlled rectifier, the control logic circuit and the starting resistor are installed On the rectifying disk of the rotor of the synchronous motor, the silicon controlled rectifier is a three-phase half-controlled bridge rectifier circuit, the starting resistor is composed of a plurality of resistors connected in series, and the three-phase AC output of the AC exciter U, V and W are connected to the input of the thyristor rectifier, and the DC output of the thyristor rectifier is connected to the armature excitation coil, and the control logic circuit includes a thyristor synchronous pulse trigger control circuit 5-1, and the controllable The silicon synchronous p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com