Fan-type motor centrifugal switch

A centrifugal switch and fan technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the length of the rotating shaft, weakening the elasticity of the moving contact reed, destroying the ecological balance, etc., and achieving the effect of enhancing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

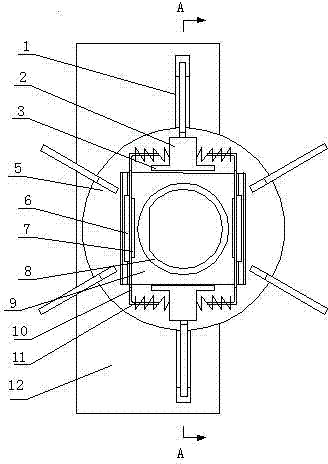

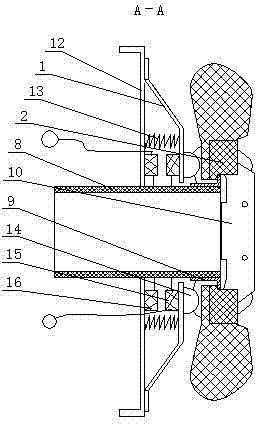

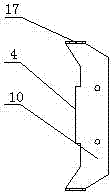

[0020] The centrifugal switch of the fan type motor as shown in the figure is provided with a rotating shaft, and the fan impeller 5 is sleeved axially slidably on the rotating shaft. figure 1 , figure 2 It can be seen that the rotating shaft is an axle sleeve 8, which is more convenient to connect the present invention with the motor shaft during use. The present invention is characterized in that the upper and lower sides of the front side of the fan impeller 5 are provided with two-way spring seats 2, the two-way spring seats 2 are symmetrical and parallel to each other, and the rotating shaft on the front side of the fan impeller 5 is provided with a centrifugal counterweight clamping plate 9. The upper and lower sides of the plate 9 are stuck between the two spring seats 2, so that the fan impeller 5 can only move axially relative to the centrifugal counterweight clamp plate 9, and cannot rotate relatively. It can be seen from the figure that the two spring seats 2 are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com