Vertical double-shaft four-cylinder electro-hydraulic servo testing machine

An electro-hydraulic servo and testing machine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem that anisotropic materials cannot be fully provided, and there is no synchronous feedback in the fast moving state. , can not achieve dynamic fatigue experiments and other problems, to achieve the effect of light weight, compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

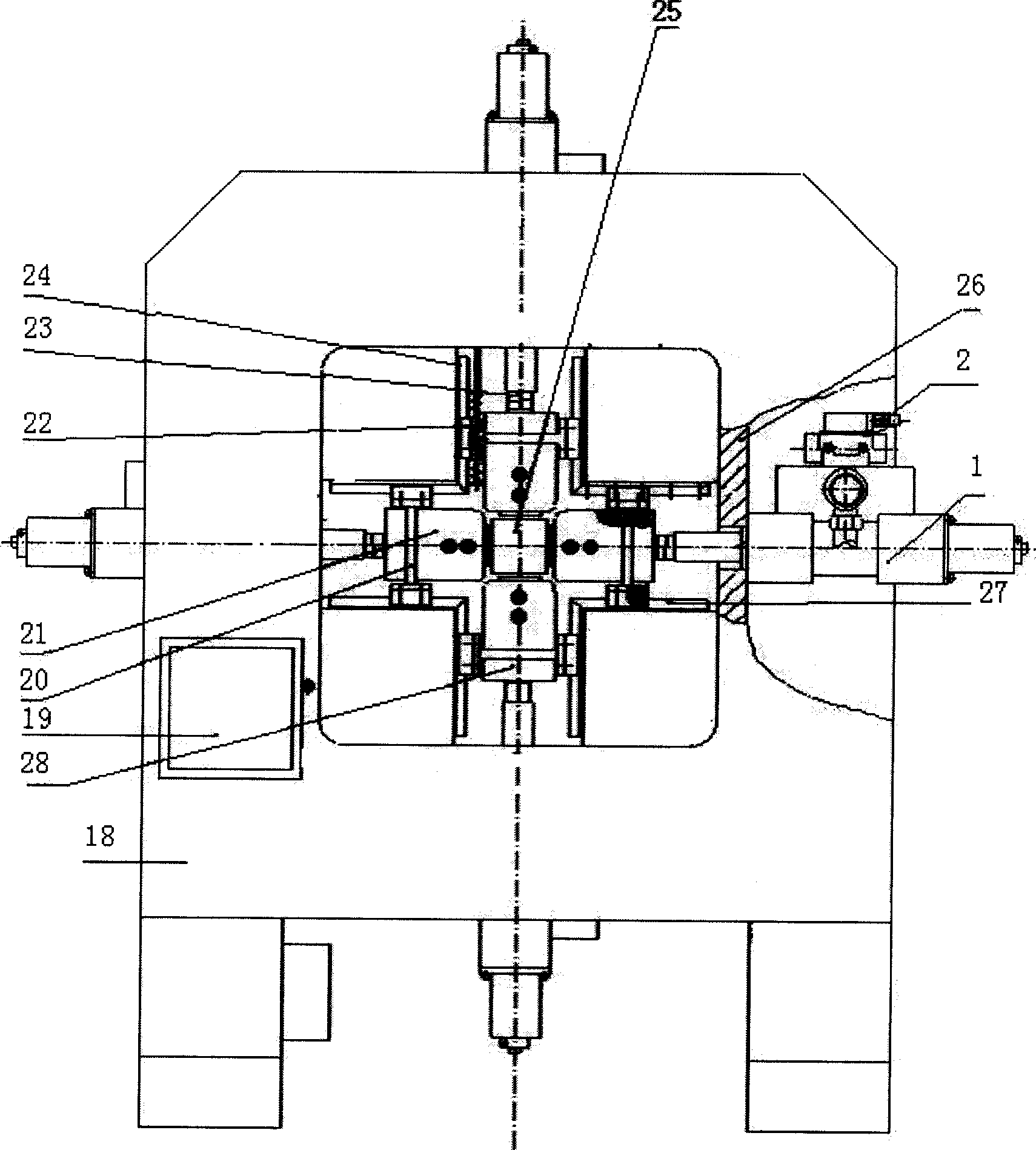

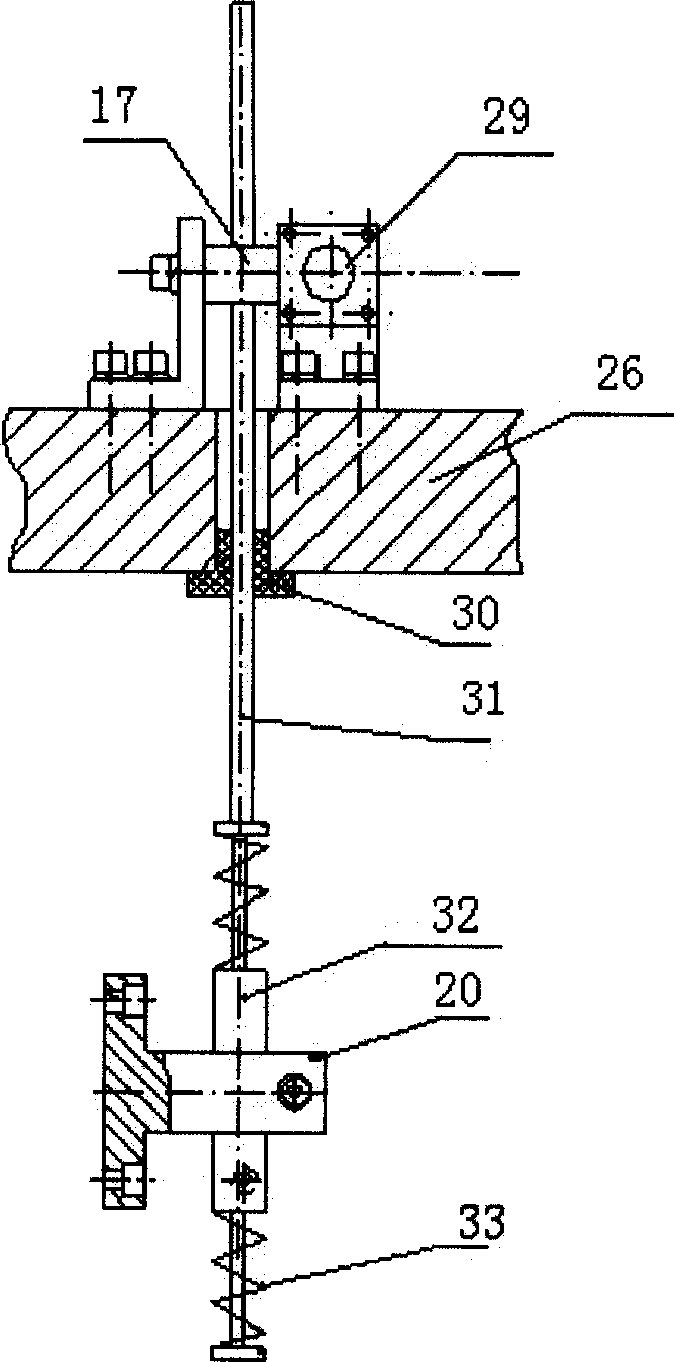

[0017] figure 1 It is a schematic diagram of a vertical main engine provided by the present invention. The main engine includes a main engine frame 26 and a horizontal and vertical loading transmission system, and both the horizontal and vertical loading transmission systems use an electro-hydraulic servo loading transmission system , the electro-hydraulic servo loading transmission system includes a servo cylinder 1, a servo valve, a lock pad 23, a load sensor 28, a hydraulic chuck 21, a hydraulic chuck cylinder 16, a linear guide rail 27, and a guide provided on the hydraulic chuck Plate 20 and position transmission device 22; the piston rod of the servo cylinder is connected to one end of the load sensor 28 through a lock pad 23, and the other end of the piston rod is connected to the hydraulic chuck 21; the hydraulic chuck is passed through the guide plate 20 Sliding on the linear guide rail 27, a position transmission device 22 is installed on the guide plate; wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com